Graphene in High-Barrier Food Packaging: Extending Shelf Life with Nanotechnology

Food packaging has always been about more than just containment—it is about preserving freshness, extending shelf life, and ensuring safety. Traditional materials like plastics, aluminum foils, and multilayer films offer decent protection, but they face challenges such as permeability to oxygen, moisture, and gases, which can lead to spoilage.

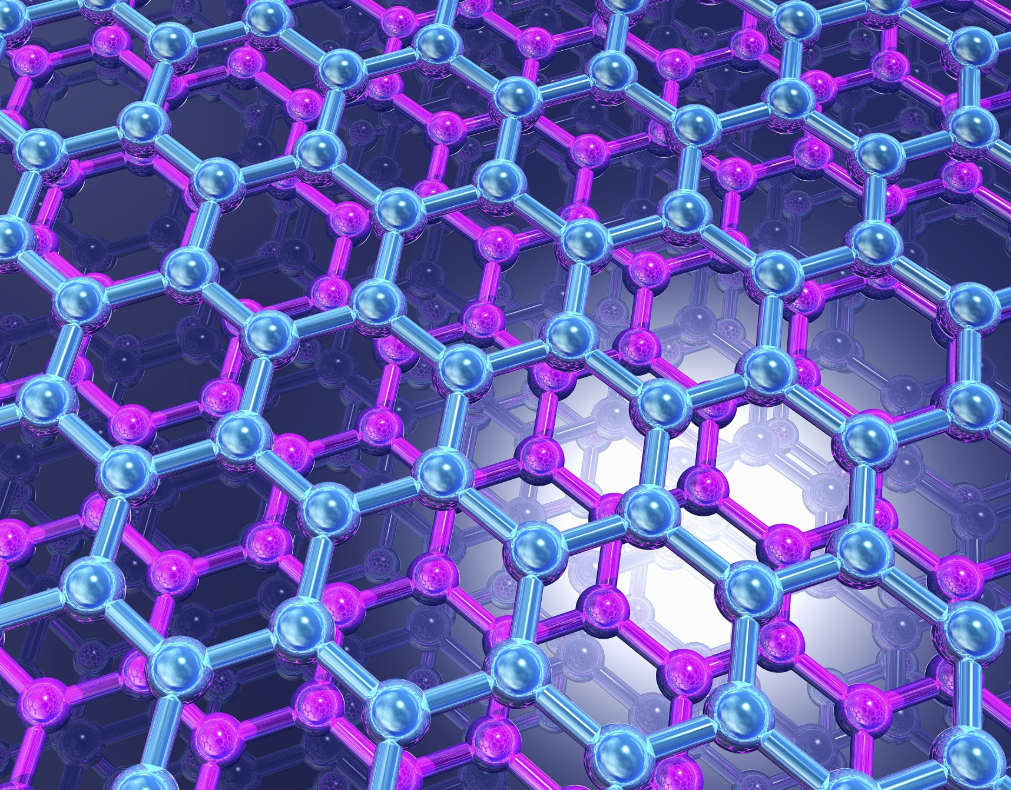

Enter graphene, a nanomaterial renowned for its exceptional barrier properties, mechanical strength, and antimicrobial activity. Its potential to transform food packaging into a high-performance, sustainable solution is attracting significant attention from both researchers and the food industry.

Why Barrier Properties Matter in Food Packaging

Effective packaging should provide:

-

Oxygen Barrier: Oxygen accelerates oxidation and bacterial growth in food.

-

Moisture Barrier: Controlling water vapor prevents sogginess or dehydration.

-

Gas Selectivity: Keeping out carbon dioxide or nitrogen where necessary.

-

Light Protection: UV rays can degrade nutrients and flavors.

Current materials often require multilayer plastic films, increasing waste and recycling complexity. Graphene’s ultra-thin yet impermeable structure offers a breakthrough alternative.

Graphene’s Advantages in Food Packaging

1. Exceptional Gas Barrier Properties

-

A monolayer of graphene is virtually impermeable to gases like oxygen and carbon dioxide.

-

Even when used in small concentrations within polymer composites, graphene dramatically reduces gas transmission rates.

2. Mechanical Reinforcement

-

Graphene nanosheets strengthen polymer films, making them more resistant to tearing, punctures, and wear.

-

Thinner yet stronger packaging materials reduce plastic usage.

3. Antimicrobial Activity

-

Graphene oxide (GO) and reduced graphene oxide (rGO) show antibacterial effects, reducing microbial contamination.

-

This feature is especially useful in meat, dairy, and fresh produce packaging.

4. Thermal Stability & UV Protection

-

Graphene absorbs UV light, protecting food from photo-degradation.

-

It improves the heat resistance of films, useful for microwave or sterilization processes.

5. Sustainability

-

By extending shelf life, graphene-based packaging reduces food waste, a major contributor to global carbon emissions.

-

Lightweight packaging lowers transportation costs and environmental footprint.

Applications of Graphene in Food Packaging

-

Modified Atmosphere Packaging (MAP)

-

Combining graphene-polymer films with MAP can maintain optimal oxygen and CO₂ balance for perishable foods like meat and vegetables.

-

-

Active & Smart Packaging

-

Graphene sensors integrated into packaging can detect freshness, pH changes, or spoilage gases, giving real-time quality monitoring.

-

-

Edible Coatings

-

Graphene oxide dispersed in edible polymers can form thin, transparent coatings on fruits or bakery products, slowing moisture loss.

-

-

Sustainable Plastic Alternatives

-

Blending graphene with biodegradable polymers (PLA, starch-based films) improves performance without relying on petroleum plastics.

-

Research & Industry Progress

-

Graphene Nanoplatelets in PET Films: Studies show oxygen permeability can be reduced by up to 70% with low graphene loading.

-

Graphene Oxide in Chitosan Films: Demonstrates antimicrobial and moisture barrier properties for fresh produce packaging.

-

Startups & Industry Collaborations: Companies are exploring commercial graphene-polymer nanocomposites for packaging with higher recyclability.

Challenges & Considerations

-

Cost & Scalability: Producing high-quality graphene at industrial scale must become more affordable.

-

Food Safety Regulations: Graphene’s interaction with food must be thoroughly evaluated for toxicology and migration limits.

-

Processing Compatibility: Packaging lines must adapt to incorporate graphene-based materials.

Graphene could revolutionize food packaging by enabling lightweight, durable, high-barrier, and intelligent packaging systems. While challenges in cost and regulation remain, rapid progress in graphene composites, scalable synthesis, and smart packaging integration points toward commercial adoption in the next decade.

If successful, graphene-enhanced packaging will not only extend shelf life but also reduce food waste, improve safety, and contribute to a sustainable food supply chain.