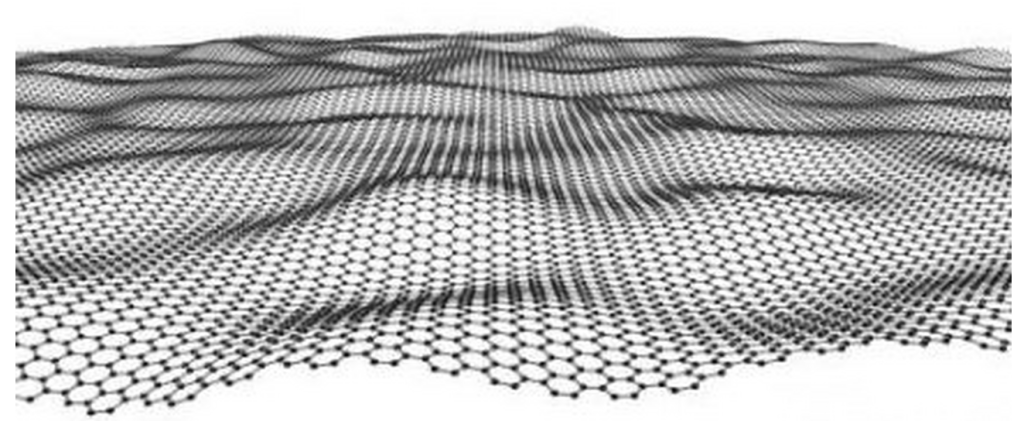

Graphene in High-Temperature Resistant Coatings

Graphene, with its outstanding thermal stability, high thermal conductivity, oxidation resistance, and exceptional mechanical strength, has emerged as a vital additive in high-temperature resistant coatings. These coatings are designed to protect materials and components from extreme heat, oxidation, and thermal fatigue, making them indispensable in industries such as aerospace, automotive, metallurgy, and power generation.

How Graphene Enhances High-Temperature Coatings

- High Thermal Conductivity

- Graphene has a thermal conductivity of up to 5300 W/m·K, enabling efficient heat dissipation and reducing localized overheating.

- Example: Graphene coatings on jet engine blades evenly distribute heat, preventing thermal stress and extending service life.

- Oxidation Resistance

- Graphene forms a dense barrier that prevents oxygen and moisture from penetrating, protecting the underlying material from oxidation.

- Example: Graphene coatings on steel furnace linings significantly reduce oxidation, improving durability in high-temperature environments.

- Thermal Stability

- Graphene remains stable at temperatures exceeding 600°C in air and up to 3000°C in inert conditions.

- Example: Reactors coated with graphene can withstand extreme thermal cycles without degradation.

- Mechanical Strength

- With a tensile strength of 130 GPa, graphene enhances the structural integrity of coatings, preventing cracking under thermal expansion and contraction.

- Example: Graphene-reinforced coatings on bridge components prevent thermal fatigue and extend their operational lifespan.

- Lightweight Material

- Graphene-based coatings offer the same or better performance as traditional ceramic or metallic coatings while being significantly lighter.

- Example: Aircraft thermal barrier coatings with graphene reduce overall weight, improving fuel efficiency and heat resistance.

Key Applications of Graphene High-Temperature Coatings

1. Aerospace

- Use: Protects components such as turbine blades, exhaust nozzles, and heat shields from extreme heat and oxidation.

- Example: A commercial jet engine equipped with graphene-coated turbine blades demonstrated increased oxidation resistance and a reduction in thermal fatigue.

2. Automotive

- Use: Applied to exhaust systems, turbochargers, and engine components to protect against heat-induced corrosion and wear.

- Example: Graphene coatings on exhaust manifolds improve thermal resistance and extend component lifespans under high-temperature conditions.

3. Metallurgy and Industrial Furnaces

- Use: Protects furnace linings, kilns, and steel production equipment from thermal degradation and scaling.

- Example: In a steel plant, graphene coatings on high-temperature furnaces reduced heat loss and energy consumption by 15%.

4. Power Generation

- Use: Applied to turbines, boilers, and heat exchangers in coal, nuclear, and gas power plants to improve thermal efficiency and prevent oxidation.

- Example: A nuclear power facility used graphene coatings on turbine blades, resulting in enhanced performance and reduced downtime.

5. Infrastructure

- Use: Used in the construction of bridges, tunnels, and steel structures to protect against high temperatures and environmental factors.

- Example: A suspension bridge utilized graphene high-temperature coatings to prevent corrosion and heat damage to steel girders.

Advantages of Graphene-Based High-Temperature Coatings

- Exceptional Heat Resistance

Graphene coatings maintain integrity and performance under extreme thermal conditions. - Superior Thermal Management

High thermal conductivity prevents overheating and reduces thermal fatigue. - Oxidation Protection

Acts as a barrier against oxygen and reactive species, extending the lifespan of materials. - Lightweight and Durable

Graphene provides advanced protection without adding significant weight. - Cost-Effective

Reduces maintenance costs and increases efficiency by improving durability and heat tolerance.

Future Directions for Graphene High-Temperature Coatings

- Improved Dispersion Techniques

Research into better dispersion of graphene in coating matrices to ensure uniform and optimal performance. - Cost Reduction

Developing cost-effective graphene production processes to make high-temperature coatings more affordable for mass adoption. - Hybrid Coatings

Combining graphene with ceramics or metals to create composite coatings with enhanced properties for extreme environments. - Eco-Friendly Solutions

Designing graphene-based coatings with minimal environmental impact and low VOC emissions. - Advanced Applications

Exploring the potential of graphene coatings in cutting-edge fields like hypersonic vehicles and space exploration.

Conclusion

Graphene high-temperature coatings provide unmatched thermal and mechanical protection, enabling industries to operate efficiently under extreme conditions. As production technologies improve, these coatings are expected to become a cornerstone of thermal management solutions across aerospace, automotive, metallurgy, and beyond. Their lightweight nature, durability, and cost-saving potential make them a transformative innovation for modern industry.