Graphene in Multi-Functional Protective Coatings: Fire, Corrosion, and EMI Shielding in One Solution

Protective coatings are indispensable in modern industries, safeguarding materials and structures from fire hazards, corrosion, and electromagnetic interference (EMI). Traditionally, separate coatings or treatments are required to address these challenges—fire-retardant paints, anti-corrosion primers, and EMI shielding layers. However, managing multiple coatings increases cost, weight, complexity, and maintenance needs.

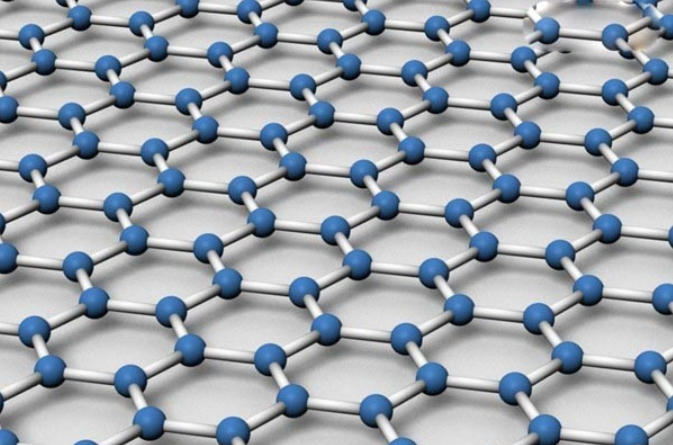

Enter graphene, the wonder material made of a single atomic layer of carbon atoms. With its unmatched mechanical strength, chemical resistance, thermal stability, and electrical conductivity, graphene offers the potential to combine multiple protective functions into a single coating system. By integrating graphene into paints, polymers, and composites, industries can create lightweight, durable, and multifunctional protective coatings that simultaneously resist fire, prevent corrosion, and shield against EMI.

Why Graphene for Multi-Functional Coatings?

Graphene brings a unique blend of properties that no conventional material can match:

-

Thermal Stability → Withstands temperatures above 600°C, enhancing fire resistance.

-

Barrier Protection → Impermeable to gases and liquids, preventing corrosion.

-

Electrical Conductivity → Enables EMI shielding and antistatic performance.

-

Mechanical Strength → Reinforces coatings, improving adhesion and durability.

-

Lightweight Nature → Provides protection without adding bulk—critical for aerospace and automotive industries.

-

Eco-Friendly Potential → Reduces reliance on toxic flame retardants and heavy metals.

This multi-dimensional performance makes graphene an ideal additive for next-generation protective coating systems.

Mechanisms of Graphene in Protective Coatings

1. Fire Resistance

-

Thermal Barrier Effect: Graphene layers slow down heat transfer and flame spread.

-

Char Formation: Promotes protective char layers in polymer matrices, reducing flammability.

-

Synergistic Performance: Works well with traditional flame retardants, lowering the required dosage of toxic chemicals.

2. Corrosion Protection

-

Impermeable Shield: Prevents oxygen, water, and chloride ions from penetrating coatings.

-

Tortuous Path Effect: Graphene dispersions create a maze that slows down corrosive agent diffusion.

-

Reinforcement: Enhances coating toughness, reducing microcracks that lead to corrosion.

3. EMI Shielding

-

Electrical Conductivity: Graphene absorbs and reflects electromagnetic waves.

-

Lightweight EMI Layers: Replaces bulky metal-based EMI shields.

-

Dual Functionality: Provides EMI protection while maintaining corrosion and fire resistance.

Industrial Applications

1. Aerospace and Aviation

-

Aircraft fuselage and interior panels require lightweight coatings with fire safety and EMI shielding.

-

Graphene coatings reduce the risk of fire in cabins, protect against corrosion in harsh climates, and shield avionics from electromagnetic radiation.

2. Automotive and Electric Vehicles (EVs)

-

EVs need fire-retardant coatings for battery packs, anti-corrosion protection for chassis, and EMI shielding for sensitive electronics.

-

Graphene coatings provide an integrated solution, reducing overall system weight and improving safety.

3. Marine and Offshore Structures

-

Ships and offshore oil rigs face corrosive seawater, fire hazards, and EMI disruptions.

-

Graphene multi-functional coatings extend service life, improve safety, and cut maintenance costs.

4. Electronics and Telecommunications

-

Smartphones, 5G base stations, and IoT devices require EMI shielding.

-

Graphene coatings act as lightweight conductive shields, while also providing heat and corrosion resistance.

5. Energy Infrastructure

-

Power plants, wind turbines, and solar farms face corrosion, EMI interference, and fire risk.

-

Graphene coatings protect infrastructure while ensuring long-term stability.

6. Defense and Military

-

Tanks, ships, and radar systems need robust multi-protection against harsh environments, fire, and EMI.

-

Graphene coatings reduce weight while providing battlefield resilience.

Case Studies and Research Insights

-

University of Manchester: Developed graphene-based coatings with both anti-corrosion and EMI shielding properties.

-

Korean Research Teams: Demonstrated graphene-polymer composites with excellent fire-retardant performance for aerospace use.

-

European Union Projects: Testing graphene coatings for ship hulls and offshore platforms combining rust resistance and fire safety.

-

Commercial Startups: Emerging companies are developing graphene-based conductive paints for EMI shielding in electronics.

Advantages Over Traditional Coatings

-

Three-in-One Functionality → Fire, corrosion, and EMI protection in one system.

-

Lightweight Solution → Critical for aerospace, EVs, and portable electronics.

-

Durability → Extends maintenance cycles, reducing costs.

-

Environmental Benefits → Reduces use of toxic flame retardants and heavy metals.

-

Customizable → Graphene can be engineered into paints, sprays, epoxies, or polymer composites.

Market Potential

The global protective coatings market is projected to surpass USD 50 billion by 2032, driven by demand in aerospace, automotive, electronics, marine, and energy sectors.

-

EMI Shielding Market → Expected to exceed USD 10 billion by 2030.

-

Fire-Retardant Coatings Market → Growing rapidly due to stricter safety regulations.

-

Anti-Corrosion Coatings Market → Already a USD 40+ billion industry.

By combining these three functionalities, graphene multi-functional coatings could disrupt multiple markets simultaneously.

Challenges and Considerations

-

Dispersion and Uniformity → Achieving even graphene distribution in coatings.

-

Scalability → Large-scale production of high-quality graphene at reasonable cost.

-

Standardization → Lack of universal testing protocols for graphene coatings.

-

Cost vs. Performance → Current costs may limit adoption in low-margin industries.

-

Regulatory Approval → Especially important for aerospace, defense, and medical sectors.

Future Outlook

The future of graphene multi-functional coatings is promising, with several trends expected:

-

Smart Coatings → Graphene coatings that detect fire, corrosion onset, or EMI disturbances and respond dynamically.

-

Hybrid Materials → Graphene combined with ceramics, polymers, or metals for enhanced performance.

-

Mainstream Adoption in EVs → Graphene coatings for battery safety and EMI shielding.

-

Next-Gen Electronics → Graphene conductive coatings as standard for consumer electronics.

-

Sustainable Infrastructure → Bridges, railways, and buildings using graphene protective paints for extended service life.

As graphene costs decrease and production scales up, multi-functional coatings will become standard in industries requiring safety, durability, and high performance.

Graphene in multi-functional protective coatings represents a major leap forward in material science. By combining fire resistance, corrosion protection, and EMI shielding into a single solution, graphene offers unmatched performance for industries ranging from aerospace and automotive to energy and defense.

The ability to replace multiple coatings with one graphene-based layer means reduced costs, lower weight, and simplified maintenance. While challenges remain in scalability, cost, and standardization, the rapid pace of research and commercialization suggests that graphene will soon dominate the protective coatings market.

In the coming years, graphene will not just protect materials from fire and rust but also secure electronics from interference, making it the material of choice for next-generation protective systems.