Graphene in Next-Gen Solar Thermal Collectors

Unlocking Ultra-Efficient Solar Energy Conversion with Graphene

As the world transitions toward clean and renewable energy, solar power continues to dominate global investment and innovation. While photovoltaic (PV) systems convert sunlight directly into electricity, solar thermal collectors capture solar radiation as heat — an approach vital for water heating, industrial processes, and space heating.

However, traditional solar thermal materials face limitations in absorptivity, thermal stability, and energy retention efficiency. This is where graphene, the atom-thin carbon material known for its exceptional thermal conductivity and broadband light absorption, offers a revolutionary improvement.

With graphene’s integration, next-generation solar thermal collectors can achieve higher efficiency, lower heat loss, and improved durability, enabling a new standard in sustainable energy harvesting.

Why Graphene Matters in Solar Thermal Systems

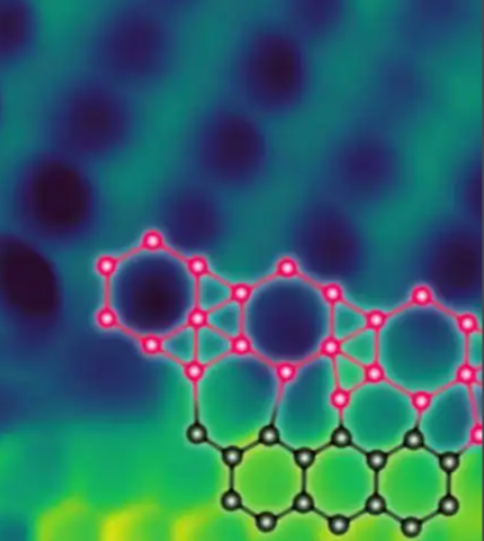

Graphene is a two-dimensional sheet of sp²-bonded carbon atoms arranged in a honeycomb lattice. Its unique structure results in properties highly desirable for solar energy applications:

| Property | Typical Value | Relevance to Solar Thermal Systems |

|---|---|---|

| Thermal conductivity | up to 5000 W/m·K | Rapid heat transfer and uniform temperature distribution |

| Optical absorption | ~2.3% per layer (broadband) | Excellent solar spectrum absorption |

| Emissivity | Tunable (0.03–0.9) | Enables selective absorption control |

| Chemical stability | Up to 600°C in air | Resistant to oxidation and degradation |

| Mechanical strength | 200× stronger than steel | Long-lasting coatings and films |

These attributes make graphene and its derivatives — particularly graphene oxide (GO) and reduced graphene oxide (rGO) — ideal for improving solar absorbers, heat exchangers, and thermal storage systems.

1. Enhancing Solar Absorptivity with Graphene Coatings

Broadband Light Absorption

Graphene exhibits exceptional absorption across the UV, visible, and infrared spectra, making it ideal for solar energy harvesting. Even a single layer absorbs ~2.3% of incident light — a significant amount considering its atomic thinness. When used as a nanocomposite coating, it enables nearly total solar absorption with minimal reflection losses.

Graphene-Based Selective Absorber Coatings

In advanced solar thermal collectors, selective surfaces must absorb sunlight efficiently while minimizing infrared emission (heat loss). Graphene, with tunable emissivity, can be engineered to act as a “spectrally selective” layer.

Studies show that graphene-coated aluminum and copper substrates achieve solar absorptance > 95% and thermal emittance < 10%, outperforming traditional black chrome or TiNOx coatings.

Advantages

-

High stability under intense solar radiation

-

Reduced oxidation and surface degradation

-

Lightweight, flexible application for flat or curved collectors

Applications:

-

Flat-plate solar collectors

-

Parabolic trough receivers

-

Solar tower absorbers

2. Graphene Nanofluids for Enhanced Heat Transfer

Another cutting-edge innovation is the use of graphene-based nanofluids — fluids containing dispersed graphene or graphene oxide nanosheets — to significantly improve heat transfer performance in solar thermal systems.

Why Nanofluids Work

Traditional heat transfer fluids like water, ethylene glycol, or oil have relatively low thermal conductivities.

By adding a small amount of graphene nanoparticles (0.01–0.1 wt%), the fluid’s effective thermal conductivity can increase by 20–40%, enabling faster heat transport and better energy utilization.

Experimental Data

-

0.05 wt% graphene in water increased thermal conductivity by ~30%.

-

rGO/ethylene glycol mixtures showed a 25% higher convective heat transfer coefficient in solar collector loops.

-

Temperature uniformity improved, reducing hot spots and efficiency losses.

Researchers from Nanyang Technological University demonstrated that graphene nanofluids increased solar collector efficiency by 15–20% compared to base fluids.

Applications:

-

Direct absorption solar collectors (DASC)

-

Parabolic concentrators

-

Hybrid PV–thermal (PV/T) systems

3. Reduced Graphene Oxide (rGO) for Selective Absorber Surfaces

Tunable Optical and Thermal Properties

Reduced Graphene Oxide (rGO) bridges the gap between insulating GO and conductive graphene. By adjusting the reduction degree, rGO’s optical absorption and emissivity can be optimized for solar thermal applications.

rGO films exhibit:

-

Strong solar absorptivity (0.95–0.97)

-

Low emissivity (~0.05–0.10)

-

Excellent adhesion and thermal stability

These films can be deposited on metals or ceramics using low-cost techniques like spray coating, dip coating, or chemical reduction — ideal for scalable solar collector manufacturing.

Case Study

An rGO–Al₂O₃ composite coating demonstrated:

-

10% efficiency improvement under 1-sun irradiation;

-

Reduced radiative heat loss at elevated temperatures (~200°C);

-

Stable optical performance after 1000 heating cycles.

4. Graphene-Enhanced Phase Change Materials (PCMs)

To maintain heat supply during cloudy periods or at night, solar thermal systems rely on phase change materials (PCMs) for energy storage.

However, PCMs typically have low thermal conductivity, limiting charging and discharging speed.

Adding graphene drastically improves performance:

-

Graphene-doped paraffin shows 3–5× higher heat transfer rate.

-

Thermal conductivity of PCM–graphene composites can reach 2–3 W/m·K, compared to ~0.2 W/m·K for pure paraffin.

-

Enhanced energy storage density and temperature stability.

These PCMs can store heat for solar water heaters, domestic heating, and industrial thermal reservoirs, providing consistent energy supply even without sunlight.

5. Durability and Environmental Benefits

Graphene-based coatings and fluids also contribute to longer operational lifetimes and sustainability:

-

Corrosion resistance: Graphene forms impermeable barriers against oxygen and moisture, protecting metal components from degradation.

-

Anti-fouling and anti-dust properties: Graphene coatings reduce surface contamination, maintaining optical efficiency.

-

Non-toxic and recyclable: Graphene is carbon-based and environmentally friendly compared to traditional metallic or ceramic nanoparticles.

Together, these features make graphene solar collectors low-maintenance and eco-conscious, aligning with global sustainability goals.

6. Comparative Performance Overview

| Material Type | Solar Absorptivity | Emissivity | Efficiency Gain | Durability |

|---|---|---|---|---|

| Traditional black chrome | 0.90 | 0.18 | Baseline | Moderate |

| TiNOx coating | 0.94 | 0.10 | +10% | Good |

| Graphene coating | 0.96–0.98 | 0.05–0.08 | +15–20% | Excellent |

| Graphene nanofluid (0.05 wt%) | — | — | +10–15% thermal efficiency | — |

These data reflect peer-reviewed experimental findings, highlighting graphene’s clear performance edge.

7. Real-World Applications and Emerging Projects

Residential Solar Water Heaters

Graphene-coated absorbers enhance heating speed and thermal retention, especially under intermittent sunlight conditions.

Countries like India and China have begun pilot projects using graphene-enhanced selective coatings for domestic hot-water systems.

Industrial Solar Heating

In industrial-scale collectors, graphene nanofluids improve thermal energy capture and transport, reducing system footprint and improving scalability.

Hybrid PV–Thermal (PV/T) Panels

Graphene films are used to cool photovoltaic cells, recovering waste heat while improving electrical output — leading to total system efficiency above 80%.

Desalination and Solar Steam Generation

Graphene aerogels and membranes serve as photothermal absorbers that efficiently convert sunlight into heat for water purification and desalination — a promising area for off-grid communities.

8. Challenges and Future Directions

| Challenge | Description | Research Focus |

|---|---|---|

| Uniform dispersion | Graphene sheets tend to agglomerate in fluids. | Use surfactants or surface functionalization. |

| Scalability | Large-scale coating or nanofluid production is still expensive. | Develop roll-to-roll coating and green synthesis. |

| Stability under long-term sunlight | Prolonged UV exposure may degrade surface quality. | Protective overcoats or hybrid ceramic composites. |

| Cost-performance optimization | Graphene price remains higher than metal oxides. | Using reduced graphene oxide or composites. |

As production technology matures and costs decline, graphene solar thermal materials are expected to become mainstream in both residential and industrial applications within the next decade.

9. The Future of Graphene Solar Thermal Collectors

The integration of graphene into solar thermal systems is driving a paradigm shift from passive collectors to highly efficient, multifunctional energy harvesters. Future designs may feature:

-

Self-cleaning, anti-reflective graphene coatings;

-

Integrated thermal sensors for system optimization;

-

Hybrid graphene nanofluids combining heat and electrical energy generation.

The result will be solar thermal systems that are not only more efficient but also smarter, more durable, and environmentally sustainable.

Graphene is redefining what’s possible in solar thermal energy.

By enabling superior solar absorption, heat transfer, and durability, it positions solar thermal collectors as key players in the clean energy transition.

From domestic water heating to industrial-scale heat recovery, graphene-enhanced technologies deliver higher performance while reducing material and maintenance costs.

As research and industrial adoption continue to accelerate, graphene-based solar thermal systems are poised to become a cornerstone of next-generation renewable energy infrastructure.

Graphene doesn’t just capture sunlight — it captures the future of sustainable energy.