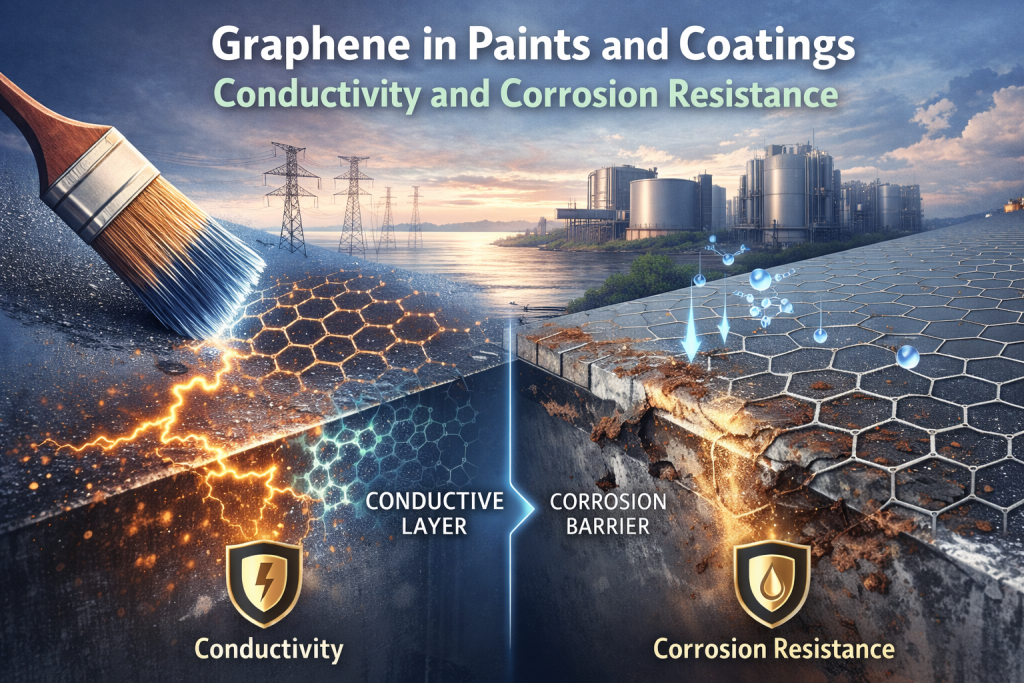

Graphene in Paints and Coatings

Enhancing Conductivity and Corrosion Resistance Through Advanced Material Design

Why Graphene Is Transforming Coating Technology

Paints and coatings have traditionally been designed for decoration and basic protection.

Today, industrial and infrastructure applications demand far more:

-

Long-term corrosion resistance

-

Controlled electrical conductivity

-

Reduced coating thickness

-

Extended service life in harsh environments

Graphene has emerged as a key functional material enabling coatings to move from passive protection to active performance systems.

What Makes Graphene Suitable for Coatings?

Graphene is a two-dimensional carbon material with:

-

Extremely high aspect ratio

-

Excellent chemical stability

-

Superior barrier properties

-

Electrical conductivity when properly networked

In coatings, graphene does not simply act as a filler—it becomes a structural and functional element within the coating matrix.

Conductivity Enhancement in Graphene-Based Coatings

How Graphene Enables Conductivity

Graphene sheets overlap to form:

-

Lateral conductive pathways

-

Distributed conductive networks across the coating surface

Unlike traditional conductive fillers:

-

Graphene can deliver conductivity at moderate loading

-

Conductivity is often more uniform and stable

Typical applications target:

-

Static dissipation (10⁵–10⁹ Ω/sq)

-

Surface grounding

-

Sensor-enabled coatings

Comparison with Conventional Conductive Fillers

| Material | Typical Loading | Conductivity Stability | Impact on Coating |

|---|---|---|---|

| Carbon Black | High (10–20 wt%) | Moderate | Increased viscosity |

| Metal Powders | Medium–High | High | Weight & corrosion risk |

| Graphene | Low–Medium (1–5 wt%) | High | Minimal thickness impact |

Graphene enables conductivity without sacrificing coating integrity.

Corrosion Resistance: Graphene’s Core Advantage

Corrosion protection is where graphene delivers its strongest value.

Barrier Effect Against Corrosive Species

Graphene sheets create a tortuous diffusion path that:

-

Slows penetration of water, oxygen, and ions

-

Reduces coating permeability

-

Delays corrosion initiation at the substrate

Even at low loading, graphene dramatically enhances:

-

Salt spray resistance

-

Humidity resistance

-

Long-term barrier stability

Improved Adhesion and Mechanical Integrity

Graphene also:

-

Enhances coating cohesion

-

Improves adhesion to metal substrates

-

Reduces microcrack formation during thermal cycling

This leads to longer-lasting corrosion protection, especially in thin coatings.

Graphene Oxide vs Reduced Graphene in Coatings

| Property | Graphene Oxide (GO) | Reduced Graphene |

|---|---|---|

| Dispersion | Excellent | Moderate |

| Waterborne Compatibility | Very high | Limited |

| Conductivity | Low–Moderate | High |

| Corrosion Protection | Excellent | Excellent |

Design logic:

-

GO for waterborne and anticorrosive primers

-

Reduced graphene for conductive topcoats

-

Hybrid systems for multifunctional coatings

Coating System Compatibility

Graphene can be integrated into:

-

Epoxy anticorrosive coatings

-

Polyurethane topcoats

-

Acrylic and waterborne systems

-

Zinc-rich primers (hybrid designs)

It is particularly effective in thin-film, high-performance coatings.

Application Areas

Graphene-enhanced paints and coatings are increasingly used in:

-

Industrial steel structures

-

Marine and offshore assets

-

Renewable energy infrastructure

-

Battery enclosures and electronics housings

-

Chemical processing equipment

In these applications, longevity and multifunctionality are critical.

Sustainability and Lifecycle Benefits

Graphene supports sustainable coating design by:

-

Reducing coating thickness

-

Extending maintenance intervals

-

Lowering material consumption

-

Improving durability without toxic additives

This aligns with global trends toward low-VOC, long-life coating systems.

Design Considerations for Formulators

To fully realize graphene’s benefits:

-

Ensure proper dispersion and exfoliation

-

Avoid excessive shear that damages sheet structure

-

Balance graphene loading with binder flexibility

-

Validate performance under real environmental conditions

Graphene works best when treated as a design component, not a drop-in additive.

Graphene is redefining what paints and coatings can achieve.

By simultaneously enhancing conductivity and corrosion resistance, graphene enables:

-

Smarter protective systems

-

Longer service life

-

Reduced maintenance costs

As coating performance requirements continue to rise, graphene-based technologies are becoming a strategic material choice, not an experimental option.