Graphene in Self-Healing Coatings: Redefining Surface Protection

From bridges and ships to pipelines, aircraft, and consumer electronics, coatings play a critical role in protecting materials from corrosion, wear, and environmental damage. However, conventional coatings eventually degrade, crack, or delaminate, leading to high maintenance costs and safety risks.

This challenge has driven researchers to develop self-healing coatings—advanced materials that can repair themselves when damaged. Among the many approaches, graphene has emerged as a revolutionary additive, enhancing both the durability and the healing efficiency of coatings.

With its exceptional barrier properties, mechanical strength, electrical conductivity, and chemical tunability, graphene is redefining the possibilities for self-healing protective coatings across industries.

Why Graphene in Self-Healing Coatings?

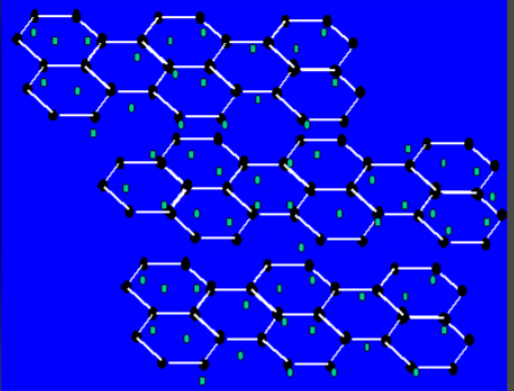

Graphene, a one-atom-thick sheet of carbon atoms, offers unique advantages:

-

Impermeability: Almost impermeable to gases and liquids, preventing corrosion agents like oxygen and water from reaching the substrate.

-

Mechanical Strength: Enhances the structural integrity of coatings.

-

Electrical Conductivity: Enables electrochemical self-healing processes.

-

High Surface Area: Provides abundant active sites for functionalization.

-

Chemical Flexibility: Easily modified with healing agents, polymers, or nanoparticles.

These properties make graphene an ideal multifunctional component in coatings designed to protect and heal simultaneously.

Mechanisms of Self-Healing in Graphene Coatings

Graphene contributes to self-healing coatings in multiple ways:

1. Physical Barrier Protection

Graphene nanosheets act as tortuous pathways, blocking corrosive species from penetrating coatings. Even before healing is triggered, graphene slows down damage progression.

2. Chemical Healing Agents

Graphene can be functionalized with healing molecules, microcapsules, or polymer networks that release active agents when cracks form, repairing the damage.

3. Electrochemical Healing

Graphene’s conductivity allows coatings to trigger localized electrochemical reactions that rebuild protective layers when exposed to external stimuli (e.g., electric fields or moisture).

4. Thermal and Photothermal Effects

Graphene absorbs light and heat efficiently. When embedded in coatings, it can activate self-healing polymers via localized heating, closing cracks and restoring structure.

Applications of Graphene Self-Healing Coatings

1. Corrosion Protection

Pipelines, offshore platforms, and ships face aggressive corrosive environments. Graphene-enhanced self-healing coatings:

-

Provide long-term corrosion resistance.

-

Reduce the need for costly re-coating and maintenance.

-

Extend the lifetime of metal infrastructure.

2. Aerospace and Automotive Coatings

Aircraft and vehicles require lightweight, durable coatings. Graphene enables:

-

Resistance to wear, oxidation, and weathering.

-

Self-repair of microcracks, reducing structural risks.

-

Longer maintenance intervals.

3. Electronics and Consumer Devices

Smartphones, laptops, and wearable electronics benefit from graphene coatings that:

-

Protect against scratches and moisture.

-

Heal minor damage autonomously.

-

Improve device lifespan.

4. Medical and Biomedical Devices

Graphene-based biocompatible coatings can be applied to implants and medical instruments, offering:

-

Self-healing antibacterial layers.

-

Resistance to body fluid corrosion.

-

Extended device safety and performance.

5. Energy Systems

Graphene self-healing coatings are also being explored for:

-

Solar panels and wind turbines, protecting surfaces from UV and moisture.

-

Battery casings, improving safety and stability.

Case Studies and Research Highlights

-

University of Manchester: Developed graphene oxide-based coatings with enhanced corrosion resistance and autonomous crack healing.

-

Indian Institute of Technology: Created graphene-polymer hybrid coatings that self-heal under UV light.

-

European Union Horizon Projects: Invested in graphene-based protective coatings for marine and industrial applications.

These breakthroughs demonstrate how graphene is moving from laboratory concepts to real-world solutions.

Benefits of Graphene in Self-Healing Coatings

-

Extended Lifetime: Coatings repair themselves, reducing replacement needs.

-

Reduced Maintenance Costs: Lower downtime and repair frequency for infrastructure and equipment.

-

Sustainability: Longer-lasting coatings reduce waste and resource use.

-

Safety Improvements: Protects critical systems like aircraft, pipelines, and energy devices.

-

Versatility: Applicable across industries, from construction to electronics.

Market Potential

The global smart coatings market is projected to surpass USD 15 billion by 2030, with self-healing coatings being a major growth segment.

At the same time, the graphene market is rapidly expanding, expected to exceed USD 3 billion by 2030, with coatings as a key application area.

The combination of these two markets suggests significant opportunities for graphene-based self-healing coatings in both industrial and consumer applications.

Challenges and Considerations

-

Scalability: Producing uniform graphene coatings on large surfaces is still challenging.

-

Cost: High-quality graphene remains expensive compared to traditional materials.

-

Standardization: Industry standards for self-healing graphene coatings are still developing.

-

Durability Testing: Long-term real-world performance requires more validation.

-

Environmental Impact: Safe disposal and recycling of graphene composites must be addressed.

Addressing these hurdles is crucial for large-scale commercialization.

Future Outlook

Graphene in self-healing coatings is moving from research to application, with future directions including:

-

Stimuli-Responsive Coatings: Triggering healing through heat, light, or electrical signals.

-

Graphene–Polymer Hybrids: Combining mechanical flexibility with chemical healing.

-

Large-Scale Industrial Adoption: Pipelines, ships, and aircraft coatings.

-

Smart Infrastructure: Coatings that not only heal but also sense damage and report structural health.

-

Eco-Friendly Coatings: Sustainable graphene composites with minimal environmental impact.

In the near future, graphene self-healing coatings could become standard for high-value industries, combining protection, intelligence, and sustainability.

Self-healing coatings represent a major leap in material science, offering a way to repair damage before failure occurs. Graphene, with its exceptional barrier, mechanical, and conductive properties, has emerged as a game-changer in this field.

From corrosion-resistant pipelines to scratch-healing smartphones, graphene-enhanced coatings promise longer lifespans, lower costs, and greater safety. While challenges remain in cost, scalability, and durability, ongoing research and industrial investment are paving the way for graphene-based smart coatings to enter mainstream use.

In the coming decade, we can expect to see graphene self-healing coatings transform industries and contribute significantly to a more sustainable and resilient future.