Graphene in Smart Surface Coatings: Enhancing Durability and Performance in Smart Manufacturing

Introduction

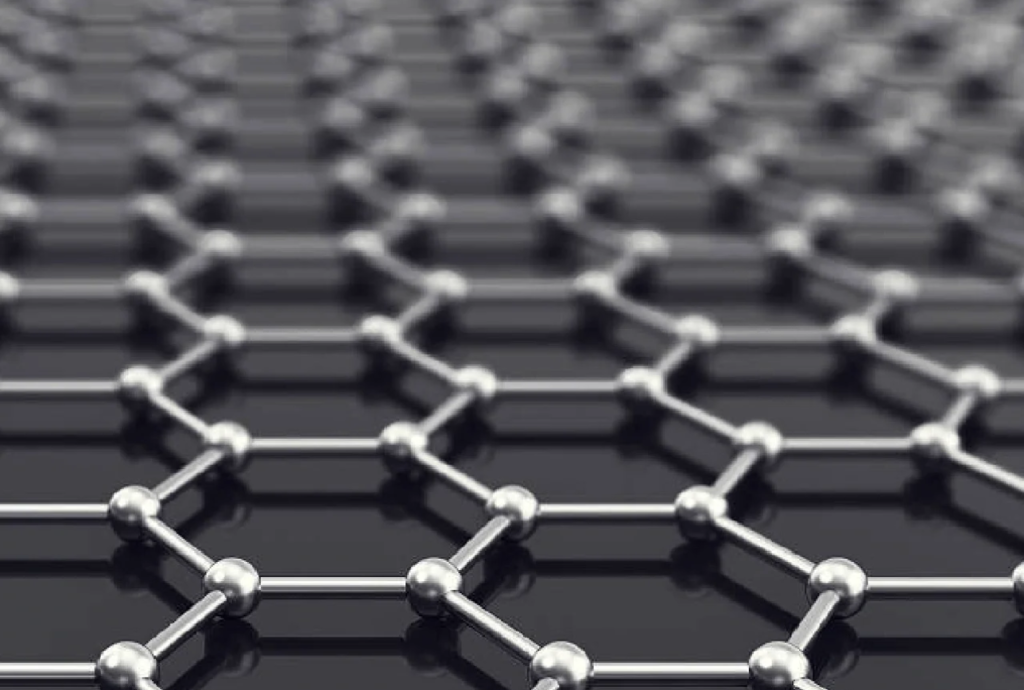

In the era of smart manufacturing, industries are constantly seeking advanced materials to improve the durability, efficiency, and sustainability of their products. Graphene, a one-atom-thick layer of carbon, has emerged as a game-changing material due to its exceptional strength, conductivity, and chemical resistance. One of its most promising applications is in smart surface coatings, where it enhances corrosion resistance, wear resistance, and overall performance of mechanical components.

This article explores how graphene-based coatings are revolutionizing surface protection in various industries, their advantages over traditional coatings, and their potential impact on the future of smart manufacturing.

1. Why Use Graphene in Smart Surface Coatings?

Graphene is an ideal material for protective coatings due to its unique physical and chemical properties:

- Superior Corrosion Resistance: Graphene forms a dense, impermeable barrier that protects surfaces from oxidation, moisture, and chemical damage.

- Outstanding Wear Resistance: Its ultra-high hardness and lubrication properties reduce surface friction, extending the lifespan of mechanical components.

- Thermal and Electrical Conductivity: Ideal for heat dissipation and anti-static applications in high-tech environments.

- Lightweight and Flexible: Graphene-based coatings maintain high strength without adding significant weight to machinery.

- Self-Cleaning and Hydrophobic Properties: Prevents dust, dirt, and water accumulation, reducing maintenance efforts.

These properties make graphene coatings highly desirable for automotive, aerospace, electronics, energy, and industrial manufacturing applications.

2. Key Applications of Graphene in Smart Coatings

(1) Corrosion-Resistant Coatings for Machinery and Equipment

Corrosion is a major concern in manufacturing plants, offshore facilities, and chemical industries. Traditional coatings often degrade over time, exposing machinery to environmental damage.

- Graphene-enhanced coatings create a strong protective layer that blocks moisture and oxygen penetration.

- Used in marine equipment, industrial pipelines, and aerospace components, graphene coatings prevent rust and extend the lifespan of metal structures.

- Smart manufacturing environments benefit from these coatings by reducing downtime and maintenance costs.

(2) Wear-Resistant Coatings for High-Friction Components

Machinery parts subjected to constant friction and mechanical stress require coatings that reduce wear and tear.

- Graphene coatings act as a lubricant layer, minimizing friction between moving parts.

- Common applications include bearings, gears, turbine blades, and robotic joints.

- Automotive and aerospace industries utilize graphene coatings to improve the longevity of engine parts and braking systems.

(3) Heat Dissipation and Thermal Management Coatings

Heat buildup can damage sensitive components in electronics and industrial machinery. Graphene’s high thermal conductivity makes it an excellent material for heat dissipation coatings.

- Electronics: Used in semiconductor manufacturing, graphene coatings help prevent overheating in processors and circuit boards.

- Energy Sector: Graphene coatings on solar panels and battery components enhance efficiency and prevent heat-related damage.

- Industrial Machinery: Applied to heat exchangers and cooling systems for better thermal management.

(4) Smart Coatings for Anti-Static and Conductive Applications

In environments where static electricity can cause damage, such as electronics manufacturing, pharmaceutical production, and aerospace, graphene coatings provide excellent anti-static properties.

- Prevents dust accumulation and reduces the risk of electrostatic discharge (ESD) damage.

- Ideal for use in cleanrooms, semiconductor fabrication, and high-precision instruments.

- Enhances performance in touchscreen displays, sensors, and IoT devices.

(5) Aesthetic and Self-Cleaning Coatings

Beyond durability, graphene coatings offer enhanced visual appeal and self-cleaning properties for consumer and industrial applications.

- Smart automotive coatings: Improve scratch resistance and hydrophobicity, keeping vehicles cleaner for longer.

- Architectural coatings: Used on building exteriors and glass surfaces to reduce maintenance and increase longevity.

- Textile and fashion industries: Smart graphene coatings add anti-bacterial and moisture-resistant properties to fabrics.

3. Advantages of Graphene Coatings Over Traditional Coatings

| Feature | Traditional Coatings | Graphene-Based Coatings |

|---|---|---|

| Corrosion Protection | Limited, degrades over time | Excellent, long-lasting barrier |

| Wear Resistance | Moderate | High, reduces friction & wear |

| Thermal Conductivity | Low | High, dissipates heat efficiently |

| Conductivity | Limited to metal-based coatings | High, suitable for anti-static applications |

| Weight | Can be heavy | Ultra-lightweight and strong |

| Environmental Friendliness | Contains toxic solvents | Eco-friendly, requires less material |

With these advantages, graphene coatings are poised to replace traditional protective coatings in many industries.

4. Future Market Potential and Industry Adoption

The global graphene coatings market is growing rapidly due to increased demand in automotive, electronics, aerospace, and industrial sectors. Key factors driving adoption include:

- Advancements in nanotechnology: Improved large-scale graphene production is making coatings more accessible and cost-effective.

- Sustainability trends: Graphene coatings reduce the need for toxic anti-corrosion agents and heavy metals.

- Growth in smart manufacturing: More industries are integrating intelligent materials to enhance product longevity and efficiency.

- Expanding use in renewable energy: Graphene coatings are playing a role in improving solar panels, batteries, and fuel cells.

Market forecasts indicate that graphene-based coatings will see exponential growth in the next decade, with adoption spreading across multiple high-tech and industrial applications.

Conclusion

Graphene coatings are transforming smart manufacturing by offering superior protection, durability, and performance. Their ability to resist corrosion, reduce wear, enhance heat dissipation, and provide anti-static properties makes them a revolutionary solution for industrial and consumer applications.

As the technology advances, we can expect graphene-based coatings to replace traditional protective materials, leading to more efficient, cost-effective, and sustainable solutions in industries ranging from automotive and aerospace to electronics and energy.

For companies looking to enhance product performance and longevity, graphene coatings represent the future of smart surface protection. As global adoption increases, businesses that invest in graphene coatings today will gain a competitive edge in the next generation of smart manufacturing.