Graphene in Thermal Management – Heat Spreading and Conductive Films

As electronic devices become increasingly powerful and compact, the need for efficient thermal management has never been greater. Excess heat generated by high-performance electronics can lead to reduced efficiency, shortened lifespan, and potential failure of components. Effective thermal management is crucial for maintaining optimal performance, particularly in devices such as smartphones, laptops, electric vehicles (EVs), and wearable technologies.

Graphene, with its remarkable thermal conductivity and flexibility, is emerging as a leading material in thermal management solutions. In this article, we will explore how graphene is used in heat spreading and conductive films, and why it’s becoming an essential material for modern thermal management applications.

1. Why Thermal Management Matters

Effective thermal management plays a critical role in a wide range of applications:

-

Electronics: As devices become more powerful, they generate more heat. Without efficient heat dissipation, this heat can damage internal components and reduce the performance and reliability of the device.

-

Electric Vehicles (EVs): EVs rely on large battery packs that produce substantial amounts of heat. Efficient thermal management is required to maintain battery health, optimize charging cycles, and ensure overall vehicle safety.

-

Wearable Devices: Small electronics such as smartwatches and fitness trackers also need effective thermal management, despite limited space for heat dissipation.

-

Aerospace and Defense: In high-tech sectors, managing heat in powerful systems and communication devices is critical for ensuring the stability and longevity of components.

2. Graphene’s Role in Thermal Management

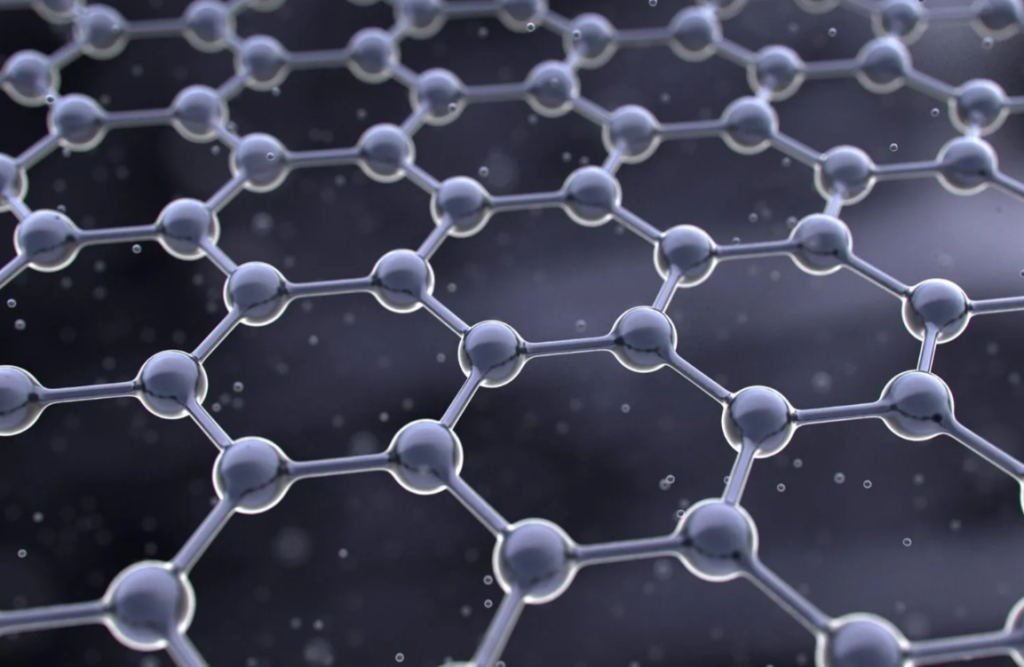

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. Its extraordinary properties—such as high thermal conductivity, mechanical strength, and lightweight nature—make it an ideal material for thermal management applications.

2.1 Heat Spreading with Graphene

In many electronic devices, heat tends to accumulate in specific regions, especially around high-performance components like microprocessors, power transistors, and LEDs. Without efficient heat spreading, localized heat buildup can cause these components to overheat, affecting their performance and longevity.

Graphene, with its ultra-high thermal conductivity, can spread heat uniformly across the surface, ensuring that no one area gets excessively hot. This is particularly important in compact devices where traditional heat sinks or fans might not be practical.

2.2 Graphene Conductive Films

Graphene-based conductive films are being used to enhance thermal dissipation in a variety of devices. These films can be applied directly to the surface of electronic components or integrated into thermal interface materials (TIMs). The films act as thermal bridges, conducting heat away from heat-sensitive components and distributing it over a larger area.

Graphene conductive films are especially useful in situations where traditional materials, such as copper or aluminum, are either too bulky, too heavy, or inefficient in dissipating heat. The thinness and flexibility of graphene films make them ideal for use in thin and flexible electronics like smartphones or wearables.

3. Advantages of Graphene in Thermal Management

3.1 Ultra-High Thermal Conductivity

One of graphene’s standout properties is its extremely high thermal conductivity—around 5000 W/m·K. For comparison, copper has a thermal conductivity of approximately 400 W/m·K, and aluminum is around 200 W/m·K. This makes graphene one of the best materials for heat spreading and dissipation in modern electronics.

With graphene, heat can be dissipated more efficiently, preventing components from overheating and improving overall device performance.

3.2 Lightweight and Flexible

Unlike traditional heat management solutions, such as metal heat sinks or fans, graphene is lightweight and flexible. This is especially important in applications where space and weight are limited, such as in wearable devices or electric vehicles. The ability to integrate graphene-based solutions into flexible electronics further extends the material’s range of potential applications.

3.3 Enhanced Durability

Graphene is also known for its high mechanical strength, making it resistant to wear and damage. This durability ensures that graphene-based thermal solutions will maintain their effectiveness over time, even under challenging conditions such as high temperatures or thermal cycling.

3.4 Improved Performance

By incorporating graphene into thermal management systems, manufacturers can significantly improve the reliability and performance of devices. Graphene-based solutions allow devices to run cooler and more efficiently, which can result in longer operational lifespans, reduced risk of failure, and increased processing power.

4. Applications of Graphene in Thermal Management

4.1 Thermal Interface Materials (TIMs)

Thermal Interface Materials (TIMs) are used to improve the thermal contact between different components, such as between a microprocessor and a heat sink. Traditional TIMs, like thermal pastes or pads, are effective but can sometimes be inefficient due to their relatively low thermal conductivity.

Graphene-based TIMs outperform traditional materials by improving the heat transfer efficiency between components. By integrating graphene into TIMs, manufacturers can reduce the thermal resistance at the interface, leading to better heat dissipation and more stable device performance.

4.2 Electronics and Semiconductors

Graphene’s excellent thermal properties make it particularly useful for high-performance electronics such as microprocessors, graphics cards, and power transistors. These devices generate a significant amount of heat during operation, which must be dissipated to avoid thermal throttling or component failure. Graphene-based solutions offer a lightweight, cost-effective, and efficient way to manage the heat generated in these devices.

4.3 Electric Vehicles (EVs)

In electric vehicles (EVs), battery packs are one of the most significant sources of heat. Overheating can negatively impact battery performance, lifetime, and safety. By using graphene-based heat spreaders or thermal pads, manufacturers can enhance thermal management in EV battery packs, ensuring that heat is efficiently conducted away from critical areas and evenly distributed across the pack.

4.4 Wearable Devices

Wearable devices such as smartwatches and fitness trackers generate heat despite their small size. Graphene’s flexibility and thinness allow it to be incorporated directly into the device structure, providing efficient heat dissipation without compromising the form factor or weight. This makes graphene-based thermal solutions perfect for next-generation wearables.

4.5 Aerospace and Defense

In the aerospace and defense sectors, the performance of high-powered systems—such as radar equipment, communication systems, and satellite electronics—can be hindered by overheating. Graphene-based solutions are being explored as a way to improve thermal management in these high-performance systems, ensuring that they operate at optimal temperatures under extreme conditions.

5. Challenges and Future Directions

While graphene-based solutions offer a multitude of benefits, there are still several challenges that need to be addressed before they can fully replace or outperform traditional thermal management materials.

5.1 Production Scalability

The production of high-quality graphene sheets and films at a large scale remains a significant challenge. Ensuring that graphene can be produced at an economically viable scale while maintaining consistency and quality is key to its widespread adoption in thermal management.

5.2 Integration with Existing Systems

Integrating graphene-based solutions into existing systems, such as traditional heat sinks or battery packs, can be technically challenging. The material properties of graphene, such as its nano-scale structure, may require advanced fabrication techniques to ensure compatibility with other materials.

5.3 Cost

Although graphene is increasingly affordable, the cost of incorporating it into thermal management systems can still be high, especially in comparison to traditional materials like copper or aluminum. Further research and development into cost-effective production techniques will be necessary to bring the price down for mass-market applications.

Graphene has emerged as a revolutionary material in the field of thermal management. Its exceptional thermal conductivity, lightweight nature, and flexibility make it a perfect solution for heat spreading and conductive films in high-performance applications across a wide range of industries, from electronics and wearables to electric vehicles and aerospace.

As production methods improve and costs decrease, the use of graphene in thermal management will become more widespread, offering superior performance and reliability compared to traditional materials. The future of thermal management lies in the innovative use of graphene, helping to keep electronic devices running efficiently and extending their lifespans.