Graphene in Wearable Electronics: Flexibility Meets Functionality

👕 Introduction: The Rise of Smart Wearables

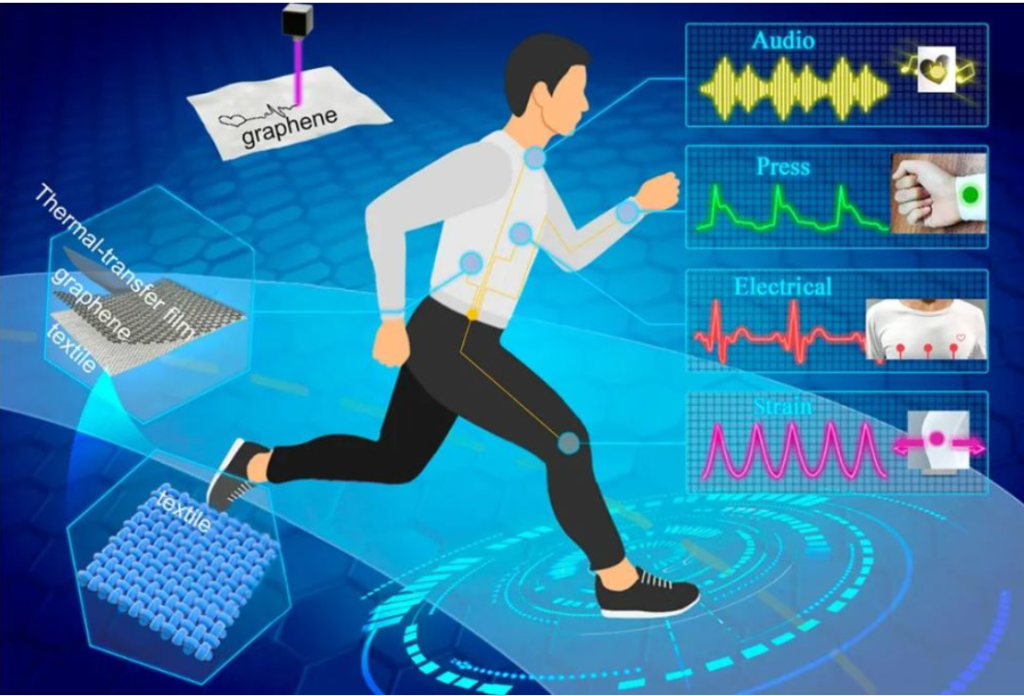

The market for wearable electronics is expanding rapidly, transforming everyday items—watches, clothing, glasses—into smart, responsive, and interactive systems. However, traditional electronic components are often bulky, rigid, or energy-inefficient.

To unlock the next generation of ultra-flexible, lightweight, and durable devices, researchers and manufacturers are increasingly turning to graphene as the material of choice.

⚙️ Section 1: Why Graphene for Wearables?

Graphene’s unique combination of properties makes it ideal for wearables:

| Property | Benefit in Wearables |

|---|---|

| High electrical conductivity | Enables sensors, circuits, electrodes |

| Mechanical flexibility | Conforms to fabric, skin, curved surfaces |

| Optical transparency | Great for smart displays and sensors |

| Lightweight (0.77 mg/m²) | No added burden to wearable items |

| Biocompatibility | Suitable for skin contact and implants |

| Thermal conductivity | Keeps devices cool and safe to touch |

These properties help graphene outperform metals like silver and copper in many wearable scenarios.

🧵 Section 2: Key Applications in Wearable Electronics

-

Smart Textiles and E-Fabrics

-

Conductive graphene inks screen-printed onto fabrics

-

Washable, stretchable circuit networks

-

Applications: health monitoring shirts, motion-detecting sleeves

-

-

Flexible Graphene Sensors

-

ECG, EEG, EMG monitoring patches

-

Sweat, temperature, strain, and pressure detection

-

Ultra-thin film sensors for wristbands or skin patches

-

-

Graphene-Based Energy Storage

-

Flexible supercapacitors and microbatteries

-

Integrated into watches, clothing, gloves

-

Fast-charging and safe operation under bending

-

-

Wearable Displays

-

Transparent conductive films for OLED/LED

-

Graphene-based touch interfaces

-

Smart glasses and AR/VR visors

-

-

Wireless & EMI Shielding Layers

-

Graphene as flexible antenna material

-

Reduces electromagnetic interference from other devices

-

🔬 Section 3: Example Devices in Development

| Device | Graphene Component | Functionality |

|---|---|---|

| ECG Shirt | Printed graphene ink traces | Monitors heartbeat and stress levels |

| Motion Sensor Gloves | Graphene film-based strain sensors | Detects gestures for VR/AR input |

| Smart Watch | Graphene supercapacitor | Power source with fast charging |

| E-Patch for Skin | Graphene biosensor | Measures pH, sweat, temperature in real-time |

| Smart Mask | Graphene filter + sensor | Filters particles and measures respiration |

These devices are already moving from lab to commercial pilot stage, with several launched in Asia and Europe.

🏭 Section 4: Manufacturing Methods for Wearable Graphene Devices

Graphene can be applied to fabrics and substrates via:

-

Inkjet printing

-

Spray coating

-

Roll-to-roll printing

-

Electrospinning

-

Laser scribing

-

Vacuum filtration on textiles

Common substrates include cotton, polyester, silk, PET, polyimide, and TPU.

Key manufacturing factors:

| Factor | Desired Property |

|---|---|

| Flake size | Small for smooth printing |

| Surface chemistry | Must bond with polymers |

| Ink viscosity | Tuned for print head type |

| Flexibility | Survives >1000 bending cycles |

| Washability | Survives 10–30 washing cycles |

🧪 Section 5: Lab Test Case – Graphene Strain Sensor Patch

Test Parameters:

-

Substrate: TPU film

-

Graphene: RGO dispersion (GR-XFZ20)

-

Sensor range: 0.1–30% strain

-

Response time: < 150 ms

-

Cyclic stability: > 5000 cycles

Result:

-

Linear piezoresistive response

-

Robust skin adhesion

-

Stable under bending, twisting, and washing

Applications: Fitness tracking, motion analysis, injury recovery

🌍 Section 6: Real-World Use Cases and Partnerships

-

University of Manchester x Vollebak

-

Graphene Jacket with thermoregulation and anti-bacterial layers

-

-

Huawei

-

Patented graphene cooling layers in smartwatches and phones

-

-

Graphene Flagship (EU)

-

R&D funding for flexible bio-electronic skin patches

-

-

Ningbo GrapheneRich NanoTech

-

Offers pre-dispersed RGO inks and pastes for flexible electronics

-

🔮 Section 7: Challenges and Opportunities

| Challenge | Opportunity |

|---|---|

| Ink stability | Use functionalized graphene or surfactants |

| Device durability | Develop multilayer encapsulation |

| Mass production | Adopt roll-to-roll coating systems |

| Power integration | Combine with flexible energy storage |

| Biocompatibility | Use high-purity RGO with surface modification |

As wearable devices require continuous sensing and wireless data transfer, graphene’s multifunctionality becomes increasingly valuable.

📦 GrapheneRich Wearable Solutions

At GrapheneRich NanoTech, we offer:

-

Water-dispersed graphene inks for fabric and film printing

-

Flexible conductive pastes for textile integration

-

Customized formulations for screen printing, spray coating, or slot-die methods

-

Surface-treated RGO with low resistance and strong adhesion

Support includes:

-

Printable viscosity range: 80–1500 cps

-

Customization for cotton, polyester, polyimide substrates

-

Optional stretch or wash durability enhancements

🧪 Free samples and testing support available.

📩 Contact: graphenerich.com | WhatsApp: +86 136 1588 2924

📈 Conclusion: Enabling the Next Generation of Smart Living

Graphene’s combination of electrical conductivity, flexibility, and lightweight performance makes it indispensable in the future of wearable electronics. From health monitoring to fashion, graphene is not just a material—it’s an enabler of human-centric innovation.

If you’re developing wearable devices, contact us to explore how GrapheneRich solutions can help you bring products from prototype to market—smarter, faster, and better.