Graphene Membranes for Gas Separation: Tuning Selectivity at the Atomic Scale

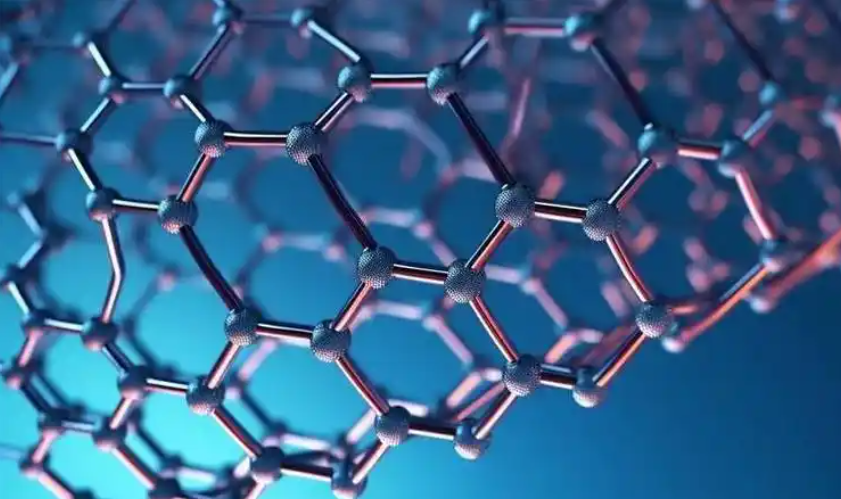

Gas separation is critical for industries ranging from natural gas processing and hydrogen production to carbon capture and semiconductor manufacturing. Traditional membranes often face a trade-off between permeability and selectivity. Graphene-based membranes, especially graphene oxide (GO) and nanoporous graphene, offer a game-changing solution due to their atomic thickness and tunable pore structures.

🔹 1. Why Graphene is Ideal for Gas Separation

-

One-atom-thick layer = minimal resistance

-

Precise control of pore size down to sub-nanometer scale

-

Functionalizable surfaces for selectivity tuning

-

High chemical and thermal stability

🔹 2. Types of Graphene Membranes

a. Nanoporous Graphene (NG)

-

Single-layer graphene etched with pores

-

Ultra-selective for H₂/CH₄, CO₂/N₂, etc.

-

Lab-scale fabrication with ion beam or oxidative etching

b. Graphene Oxide (GO) Laminates

-

Stacked GO sheets form selective nanochannels

-

Tune interlayer spacing with chemical crosslinking or reduction

-

More scalable for industrial applications

🔹 3. Targeted Gas Separation Applications

-

Hydrogen Purification

-

H₂/CH₄ or H₂/CO₂ for fuel cells and ammonia production

-

-

Natural Gas Upgrading

-

CO₂ removal, N₂ rejection

-

-

Air Separation

-

O₂/N₂ purification

-

-

Carbon Capture

-

Post-combustion CO₂/N₂ capture from flue gas

-

🔹 4. Recent Research and Industrial Progress

-

MIT: Demonstrated selective H₂ transport through NG

-

University of Manchester: Graphene sieves for precise molecular separation

-

EnerVenue & Samsung: Exploring GO for clean H₂ projects

-

G2O Water: Developing GO membranes for both water and gas filtration

🔹 5. Key Challenges

-

Pore engineering reproducibility

-

Mechanical stability under pressure

-

Large-scale fabrication of defect-free sheets

-

Membrane fouling and long-term performance

Graphene membranes represent a revolutionary platform for ultra-selective, energy-efficient gas separation. As manufacturing technologies improve, these atomically-thin materials will play an essential role in clean energy, climate solutions, and advanced industrial processing.