Graphene Oxide Coatings for Antibacterial Surfaces: Made in China for Public Health

Introduction

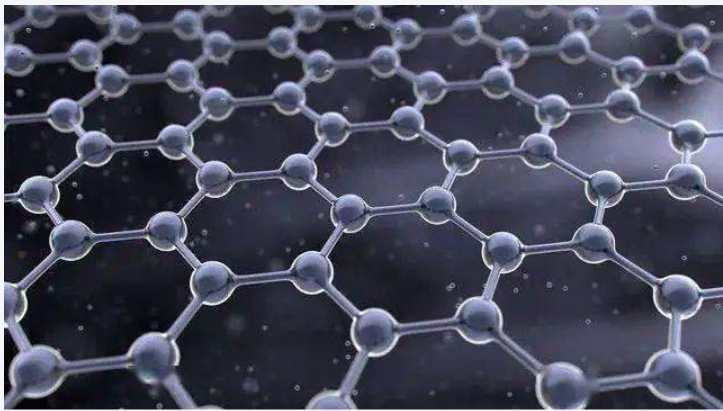

In the wake of global health crises and increasing awareness of antimicrobial resistance, surface hygiene has become a key frontier in public health. Among the various innovations, graphene oxide (GO)-based antibacterial coatings have emerged as a cutting-edge solution. Leveraging graphene oxide’s high surface area, functional oxygen groups, and unique interaction with microbial membranes, these coatings are now being mass-produced and applied across multiple sectors in China, from schools and hospitals to public transit and consumer goods.

This article explores the science behind GO antibacterial coatings, their industrialization in China, and how they are shaping a safer and smarter environment.

1. Why Graphene Oxide?

Unique Properties for Antimicrobial Action:

-

High surface area enables large contact with microbial cells

-

Oxygen-containing functional groups (–COOH, –OH, –C=O) disrupt cell membranes

-

Sharp edges of GO nanosheets physically puncture bacterial walls

-

Oxidative stress induction damages microbial DNA and proteins

Compared to traditional antibacterial agents (e.g., silver nanoparticles, quaternary ammonium), GO is:

-

Metal-free

-

Long-lasting

-

Non-leaching

-

Safe under ambient use

2. Real-World Applications in China

China is leading in the mass production and integration of GO-based coatings into end products. Below are some impactful implementations:

A. Antibacterial Paints and Wall Coatings

-

Used in hospitals, classrooms, and nursing homes

-

Offers 99.9% bacterial inactivation within 2 hours

-

Manufacturers: Suzhou Graphene Tech, Jiangsu Graphite Valley, Ningbo Advanced Materials

Case Study: A pediatric hospital in Jiangsu reported a 35% reduction in surface-level infection rates after coating high-contact areas with GO-enhanced wall paint.

B. Face Masks and Personal Protective Equipment (PPE)

-

GO integrated into melt-blown layers of masks or as spray-on surface coatings

-

Offers antiviral performance, especially against influenza and coronavirus families

-

Enhanced filtration efficiency without compromising breathability

Several GO-masks were trialed during the 2022–2023 flu season in Shanghai and Guangzhou, with promising performance in pilot studies.

C. School Desks and Educational Tools

-

GO-based antimicrobial coatings applied to desktops, writing tools, lab equipment

-

Helps reduce cross-contamination in crowded classrooms

-

Supports a safer learning environment without chemical disinfectants

A middle school in Hangzhou applied GO coatings to 80 classrooms; microbial swab counts dropped 70% over a semester compared to uncoated rooms.

D. Touchscreen Devices and Public Transportation

-

Applied to ATM machines, ticket kiosks, elevator buttons, mobile phones

-

Offers transparent, durable, and self-sanitizing surfaces

-

Industrial partners: Beijing Metro pilot project, Shenzhen smart terminal suppliers

3. Industrialization: Made-in-China Capability

A. Manufacturing of GO

China has built a robust supply chain for high-purity graphene oxide:

-

Raw material: Graphite flakes from Shandong and Heilongjiang

-

Synthesis: Modified Hummers’ method in large reactors

-

Concentration control: 0.1–10 mg/mL aqueous dispersions

-

Dispersibility: Enhanced using biocompatible surfactants (e.g., XFZ20 series)

Key players: GrapheneRich NanoTech (Ningbo), Six Carbon (Shenzhen), TimesNano (Chengdu)

B. Integration Into Coatings

-

GO is blended with polymer resins, epoxy, PU, or acrylic matrices

-

Sprayable or brushable formats enable easy field application

-

Final coatings pass ISO 22196 antimicrobial surface tests

Production lines in Zhejiang and Jiangsu now offer custom coatings for medical and consumer use.

4. Mechanisms of Antimicrobial Activity

| Mechanism | Description |

|---|---|

| Membrane Disruption | GO nanosheets interact with lipid membranes, leading to rupture |

| Oxidative Stress | Generates reactive oxygen species (ROS) that damage DNA and proteins |

| Enzyme Deactivation | Interferes with microbial metabolic pathways |

| Contact-Kill Surface | Requires no leaching, microbes perish upon contact |

Unlike chemical disinfectants, GO coatings do not degrade over time and maintain efficacy without constant reapplication.

5. Regulatory and Safety Aspects

China National Standards In Progress

-

Drafting of GO-based coating safety and performance standards began in 2022

-

Led by Tsinghua University, ShanghaiTech, and Ministry of Industry

-

Guidelines expected to include:

-

Maximum particle size

-

Biocompatibility and toxicity testing

-

Environmental release assessment

-

Early toxicological data suggest GO is safe in surface-applied formats, with minimal dermal or inhalation absorption risk.

6. Market Potential and Growth Trends

-

Estimated domestic demand for GO antibacterial coatings in China reached ¥1.2 billion (USD $160 million) in 2024

-

Expected CAGR > 25% through 2028

-

Driven by:

-

Aging population and hospital upgrades

-

School hygiene campaigns

-

Smart city deployment of public safety technologies

-

Export-ready coatings are being promoted in ASEAN, Middle East, and Europe through CE-certified partners.

7. Future Outlook

Innovations Ahead:

-

Smart Coatings: Combining GO with sensors for real-time pathogen detection

-

Self-healing Films: GO-based polymers that repair surface damage automatically

-

Multifunctional Layers: GO + AgNP + ZnO for enhanced antiviral and antibacterial synergy

-

Photothermal Coatings: Using GO’s light-absorbing properties to activate self-sterilization under sunlight

Conclusion

Graphene oxide coatings are no longer laboratory novelties—they are real, scalable, and being manufactured at volume in China. With a growing track record in public health, education, transport, and consumer safety, these coatings represent the next frontier of smart, safe, and sustainable antimicrobial materials.

Chinese companies are not only producing GO, but are actively integrating it into functional, compliant, and affordable solutions. As demand grows for contact-kill and passive protection surfaces, GO coatings are poised to become a standard in hygiene engineering worldwide.