Graphene Oxide for Anti-Bacterial Wound Dressings: Healing with Nanotechnology

In the modern era of healthcare, wound management has evolved from simple bandages to advanced bioactive dressings that promote faster healing, prevent infection, and support tissue regeneration.

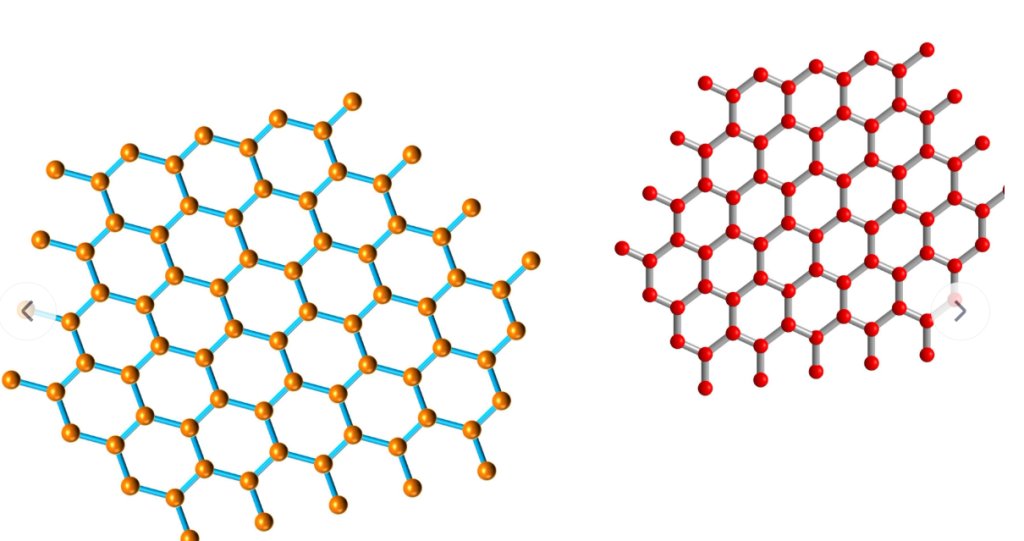

Among the most promising materials leading this evolution is Graphene Oxide (GO) — a chemically modified form of graphene rich in oxygen-containing functional groups.

Due to its strong antibacterial activity, mechanical strength, and biocompatibility, GO is now being widely explored for antibacterial wound dressings and regenerative medicine. Its unique nanostructure allows it to not only inhibit microbial growth, but also enhance cell proliferation and angiogenesis, making it a multifunctional platform for next-generation wound care.

What Is Graphene Oxide?

Graphene Oxide (GO) is a single-atomic-layer derivative of graphene, produced by the oxidation of graphite (commonly via the Hummers’ method). Unlike pristine graphene, GO contains abundant oxygenated functional groups — including hydroxyl (-OH), epoxy (-O-), and carboxyl (-COOH) groups — distributed across its surface and edges.

These oxygen groups make GO:

-

Hydrophilic (water-compatible), allowing easy dispersion in biocompatible gels or polymers.

-

Chemically active, enabling bonding with biomolecules, drugs, and polymers.

-

Tunable, as its reduction level can control conductivity, surface charge, and reactivity.

This balance between graphene’s structural strength and chemical functionality gives GO a unique advantage in biomedical applications, particularly for wound healing.

The Antibacterial Mechanisms of Graphene Oxide

Several theoretical and experimental studies have confirmed that graphene oxide exhibits potent antibacterial activity against a wide range of microorganisms, including Escherichia coli (E. coli), Staphylococcus aureus (S. aureus), and Pseudomonas aeruginosa.

1. Physical Disruption of Bacterial Membranes

The sharp edges of GO nanosheets can pierce bacterial cell walls, leading to membrane rupture and cytoplasmic leakage.

-

This “nano-knife effect” is especially effective against Gram-negative bacteria, which have thinner cell walls.

2. Oxidative Stress and ROS Generation

GO can produce reactive oxygen species (ROS) such as hydroxyl radicals and superoxides, which damage bacterial DNA, proteins, and membranes.

-

The process is amplified under light exposure (photocatalytic ROS generation).

-

The oxidative potential is tunable by controlling GO’s oxygen content and sheet size.

3. Electron Transfer Interference

GO acts as an electron sink, disrupting bacterial respiration by withdrawing electrons from microbial membranes.

-

This destabilizes metabolic pathways, inhibiting growth and replication.

4. Biofilm Inhibition

GO surfaces prevent bacterial adhesion and biofilm formation, which is critical for chronic wound infections.

-

Functionalized GO surfaces can further resist protein adsorption, minimizing microbial colonization.

Together, these mechanisms result in multi-modal antibacterial activity — a significant advantage over single-mechanism antibiotics that risk resistance development.

Promoting Wound Healing: Beyond Antibacterial Effects

While GO’s antibacterial power is crucial, its secondary biological effects are equally valuable in accelerating tissue regeneration.

1. Enhanced Cell Adhesion and Proliferation

The oxygen-containing groups on GO interact with cellular integrins, promoting fibroblast attachment and proliferation — key steps in wound repair.

Studies have shown that GO-coated polymer films enhance the growth of human dermal fibroblasts (HDFs) and keratinocytes, which are essential for epidermal recovery.

2. Angiogenesis Stimulation

Low concentrations of GO have been reported to enhance vascular endothelial growth factor (VEGF) expression, promoting new blood vessel formation and faster oxygen delivery to wounds.

3. Controlled Drug and Growth Factor Delivery

GO’s high surface area (~700–1500 m²/g) allows efficient loading and slow release of antibiotics, growth factors, or anti-inflammatory agents.

-

Example: GO–chitosan hydrogels delivering silver ions (Ag⁺) or ciprofloxacin provide dual antibacterial and healing effects.

4. Moisture Retention and Breathability

When integrated into hydrogel or polymeric matrices, GO helps maintain an optimal wound environment — moist but breathable, reducing scab formation and scarring.

Fabrication of GO-Based Wound Dressings

Graphene oxide can be incorporated into a variety of biocompatible scaffolds and hydrogel systems to form advanced wound dressings.

1. GO–Chitosan Composite Films

-

Chitosan is a natural polysaccharide with inherent antibacterial properties.

-

GO improves its mechanical strength, antibacterial efficiency, and water retention.

-

Reported tensile strength: 20–30 MPa, improved by ~50% with GO addition.

2. GO–Hydrogel Systems

-

Hydrogels made from polymers like PVA, alginate, or gelatin can be blended with GO for flexibility and sustained drug release.

-

These composites exhibit strong antimicrobial activity (>95% bacterial inhibition) and improved healing in animal models.

3. Electrospun GO Nanofiber Mats

-

GO incorporated into PCL or PLA nanofibers creates porous, breathable wound dressings.

-

Surface roughness and hydrophilicity enhance cell migration and re-epithelialization.

4. GO–Silver Nanocomposites (GO–Ag)

-

Combining GO with silver nanoparticles yields synergistic antibacterial effects, effective even against antibiotic-resistant strains.

-

GO stabilizes AgNPs, preventing aggregation and controlling ion release.

Experimental and Theoretical Data

Public studies report quantifiable results that demonstrate GO’s antibacterial and healing potential:

| Study | Material | Bacteria Tested | Inhibition Efficiency | Notable Outcome |

|---|---|---|---|---|

| Akhavan et al., ACS Nano (2010) | GO nanosheets | E. coli | >98% | Cell membrane rupture confirmed by SEM |

| Hu et al., Carbon (2012) | GO–Ag nanocomposites | S. aureus, E. coli | 99.9% | Enhanced with visible light exposure |

| Li et al., Biomaterials (2013) | GO–chitosan films | Mixed strains | 95% | Accelerated fibroblast growth |

| Jin et al., J. Mater. Chem. B (2018) | GO–hydrogel | P. aeruginosa | >90% | Faster wound closure (rat model) |

These publicly available results validate GO’s multi-functional performance and its clinical potential for wound care.

Advantages Over Traditional Antibacterial Dressings

| Feature | Traditional (e.g., silver, iodine) | Graphene Oxide-Based |

|---|---|---|

| Antibacterial Range | Narrow | Broad-spectrum (Gram+ / Gram–) |

| Resistance Development | Possible | Very low risk |

| Cytotoxicity | Medium to high (Ag⁺ toxicity) | Tunable, lower |

| Drug Delivery | Limited | Excellent (high loading) |

| Flexibility | Low | High (hydrogel and fiber forms) |

| Cost & Stability | Moderate | Increasingly scalable |

Challenges and Future Prospects

Despite its potential, several technical and biomedical challenges must be addressed before GO wound dressings see full clinical adoption:

-

Dose-Dependent Cytotoxicity

-

While low concentrations (≤50 µg/mL) promote healing, excessive GO can generate excessive ROS, harming healthy cells.

-

Optimal dosage and reduction degree (rGO vs. GO) must be carefully controlled.

-

-

Scalability and Reproducibility

-

GO synthesis via Hummers’ method must be standardized for consistent oxygen content and biocompatibility.

-

-

Long-Term Biodegradability

-

Pure GO is not inherently biodegradable; functionalization with polymers (gelatin, PEG) enhances safe clearance.

-

-

Regulatory Approval

-

GO-based dressings require rigorous ISO 10993 biocompatibility and FDA/CE certification pathways before mass production.

-

Theoretical Outlook

According to molecular dynamics simulations and density functional theory (DFT), GO’s electrostatic interaction energy with bacterial membranes (≈ –0.6 to –0.8 eV per lipid) supports strong adsorption and mechanical disruption at the nanoscale — consistent with observed experimental data.

Future Directions

Researchers are now advancing GO-based wound dressings toward multifunctional “smart” systems that can:

-

Detect infection via colorimetric or electrical signals.

-

Deliver drugs on-demand in response to pH or temperature changes.

-

Integrate wireless monitoring for continuous wound healing assessment.

Combining GO with other nanomaterials (like ZnO, Ag, or Cu nanoparticles) and bio-polymers (like collagen or alginate) is expected to yield biocompatible, cost-effective, and scalable solutions for hospitals and home-care applications.

Graphene Oxide (GO) is emerging as a revolutionary material for antibacterial and regenerative wound dressings. Its unique combination of physical membrane disruption, oxidative stress induction, and drug-carrying capacity allows it to both prevent infection and promote tissue healing simultaneously.

By integrating GO into hydrogels, nanofibers, or biopolymer films, researchers are creating next-generation wound care materials that are strong, flexible, antibacterial, and bioactive — precisely what modern medicine demands.

As manufacturing scalability and biocompatibility continue to improve, graphene oxide wound dressings could soon replace conventional products, offering safer, faster, and smarter wound healing for patients worldwide.