Graphene Oxide in Coatings and Lubricants: Advancing Corrosion Protection and Friction Reduction

Graphene oxide (GO) has gained significant attention in recent years for its unique properties, making it an ideal candidate for use in coatings and lubricants. Its remarkable mechanical, chemical, and thermal stability, combined with its ability to enhance performance in various environments, makes GO an invaluable material in industries that require advanced corrosion protection and efficient lubrication. This article explores the applications and advantages of graphene oxide in coatings and lubricants, with a focus on corrosion-resistant coatings and friction-reducing additives for lubricants.

1. Corrosion-Resistant Coatings

Corrosion is a major challenge in industries such as marine, petrochemical, and metal manufacturing, where materials are exposed to harsh environmental conditions. Graphene oxide’s high surface area and exceptional barrier properties make it a highly effective component for corrosion-resistant coatings.

Advantages of GO in Corrosion-Resistant Coatings

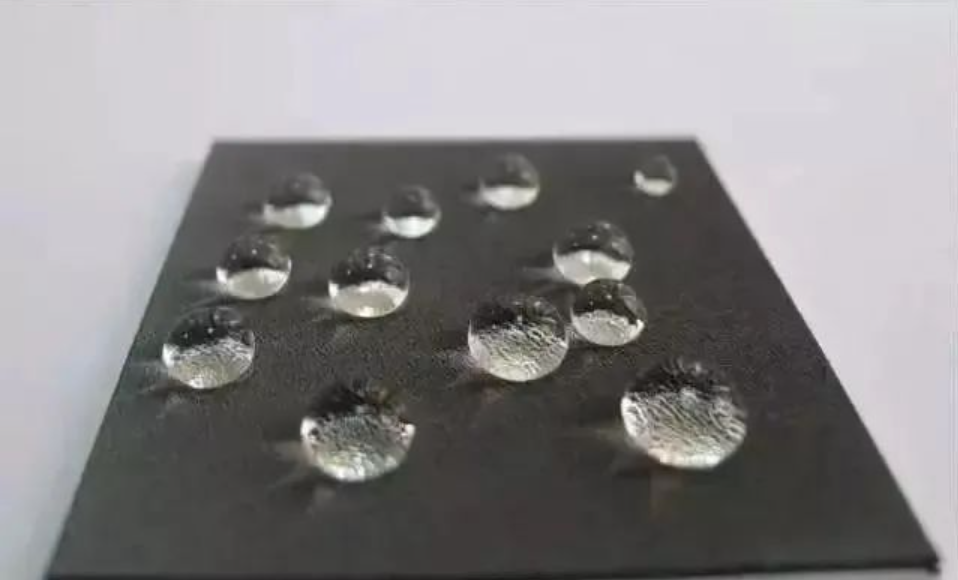

- Enhanced Barrier Properties: GO forms a protective barrier that prevents moisture, oxygen, and other corrosive agents from reaching the surface of the metal.

- Improved Durability: GO-based coatings increase the lifespan of metal surfaces by reducing the rate of corrosion and wear.

- Resistance to Harsh Environments: GO-based coatings provide superior protection in extreme conditions, including saltwater exposure and high humidity.

Applications of GO in Corrosion-Resistant Coatings

- Marine Engineering: GO-enhanced coatings are applied to ships, offshore oil rigs, and other marine structures to protect them from seawater-induced corrosion.

- Petrochemical Equipment: Equipment used in the oil and gas industry, such as pipelines and storage tanks, benefits from GO-based coatings that protect against chemical corrosion.

- Metal Protection: GO coatings are used on metal surfaces in automotive, industrial machinery, and construction applications to prevent rust and degradation.

Market Trends

As industries seek more sustainable and long-lasting solutions, the demand for advanced corrosion-resistant coatings is rising. GO’s effectiveness in improving the durability and longevity of coatings positions it as a critical material for industries that rely on metal protection, especially in environments with high corrosion risk.

2. Lubricant Additives

Graphene oxide is also being explored as an additive to enhance the performance of lubricants. Its unique structure and properties, such as high surface area and the ability to interact with surfaces at the nanoscale, make it ideal for improving the performance of lubricants, reducing friction, and extending the lifespan of mechanical components.

Advantages of GO in Lubricants

- Friction Reduction: GO helps to reduce friction between moving surfaces, leading to smoother operation and less wear on components.

- Enhanced Wear Resistance: By forming a protective layer on the surface of materials, GO enhances the wear resistance of components, thus prolonging their service life.

- Thermal Stability: GO enhances the thermal conductivity of lubricants, allowing them to better dissipate heat generated during operation.

- Compatibility: GO can be easily incorporated into various types of lubricants, including oils, greases, and dry lubricants, providing flexibility in its applications.

Applications of GO in Lubricants

- Industrial Equipment: GO-based lubricants are used in machinery, engines, and other equipment to reduce wear and improve efficiency.

- Automotive Industry: GO additives are included in motor oils and transmission fluids to improve performance, reduce engine friction, and increase fuel efficiency.

- Aerospace: GO-enhanced lubricants are used in high-performance applications, such as aerospace engines and bearings, to ensure smooth operation under extreme conditions.

- Heavy Machinery: In mining, construction, and manufacturing, GO-based lubricants reduce friction and wear, enhancing the longevity and efficiency of heavy machinery.

Market Outlook

The lubricants market is expected to grow steadily due to increasing demand for energy-efficient machinery and vehicles. Graphene oxide’s role in improving lubrication properties positions it as a promising material for enhancing the performance of both industrial and automotive lubricants.

Conclusion

Graphene oxide has proven to be a transformative material in both coatings and lubricants, offering significant advantages in terms of corrosion resistance and friction reduction. Its ability to enhance the durability and longevity of materials, reduce wear and tear, and protect against harsh environmental factors makes it invaluable in a variety of industries.

From protecting marine and petrochemical equipment to enhancing the performance of lubricants in industrial and automotive applications, graphene oxide is poised to play a key role in advancing the performance and sustainability of coatings and lubricants. As further research and development are conducted, GO is likely to become even more integrated into these industries, offering higher efficiency, longer service life, and more environmentally friendly solutions.