Graphene Oxide in Printing and Packaging: Enabling Smart Labels and Conductive Inks

The printing and packaging industries are undergoing a technological revolution, driven by the integration of advanced materials that enhance functionality and efficiency. Graphene oxide (GO) has emerged as a game-changing material, offering remarkable properties that enable the development of smart labels and conductive inks. These innovations are transforming packaging into an intelligent, interactive, and sustainable component of modern supply chains.

1. Smart Labels: Revolutionizing Tracking, Identification, and Sensing

Smart labels are a cornerstone of modern logistics, retail, and healthcare, enabling enhanced product tracking, identification, and environmental monitoring. Graphene oxide’s electrical conductivity, flexibility, and sensitivity make it an ideal material for advancing smart label technology.

Advantages of GO in Smart Labels

- Electrical Conductivity: GO-based components provide high conductivity for label circuits, ensuring reliable data transmission.

- Flexibility: The thin, lightweight structure of GO allows labels to conform to various surfaces, including curved and irregular shapes.

- Sensitivity: GO’s responsiveness to environmental changes enables the creation of sensors that detect temperature, humidity, or other factors.

- Eco-Friendliness: GO is a more sustainable alternative to traditional electronic materials, aligning with green packaging initiatives.

Applications of GO in Smart Labels

- Product Tracking: GO-based RFID tags allow real-time tracking of goods throughout the supply chain, improving logistics efficiency and reducing losses.

- Authentication: Smart labels with embedded GO can verify product authenticity, combating counterfeiting in high-value industries such as pharmaceuticals and luxury goods.

- Environmental Monitoring: GO-enabled sensors in labels detect and report storage conditions such as temperature and humidity, ensuring product quality in food and medicine.

- Interactive Labels: GO is used to create interactive labels that communicate with consumers via smartphones, providing product information or promotional content.

Market Trends

The demand for smart labels is growing as businesses seek to optimize supply chains, enhance product security, and improve customer engagement. GO’s ability to integrate multiple functionalities into a single label makes it a key enabler in this market.

2. Conductive Inks: Powering RFID and Electronic Packaging

Conductive inks are essential for creating printed electronics, such as RFID tags and interactive packaging. Traditional conductive inks rely on metals like silver, which are expensive and less sustainable. Graphene oxide offers a cost-effective and versatile alternative.

Advantages of GO in Conductive Inks

- Cost-Effectiveness: GO is more affordable than silver and other traditional conductive materials, reducing the overall cost of printed electronics.

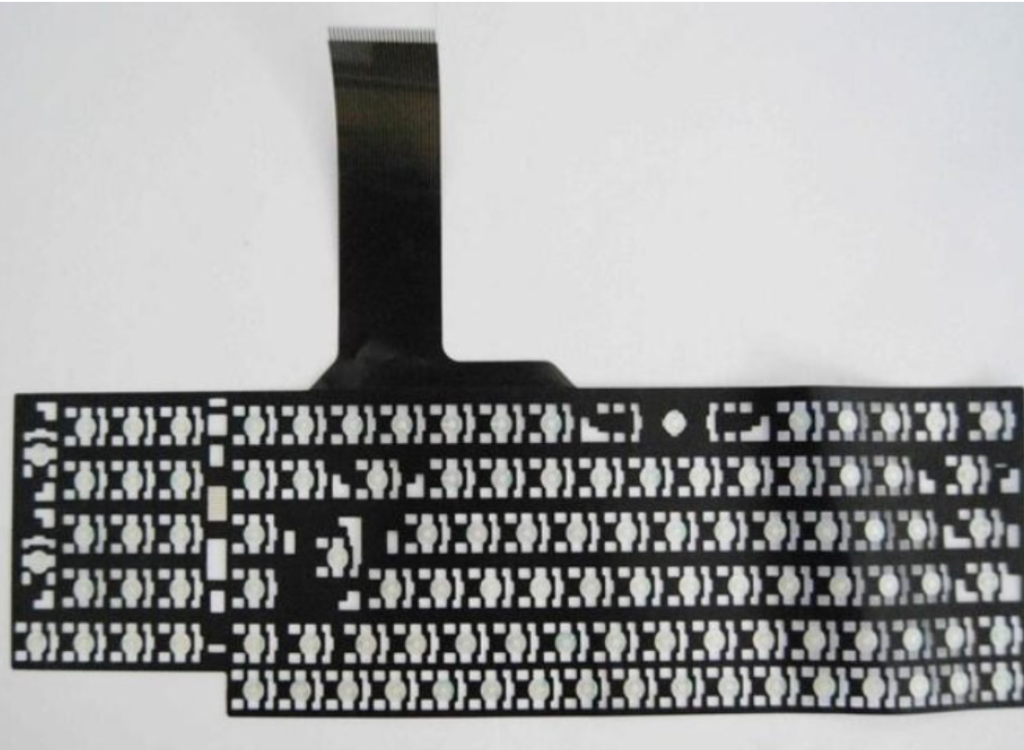

- Scalability: GO-based inks are compatible with mass printing techniques, including screen printing, inkjet printing, and roll-to-roll processing.

- Durability: GO inks are resistant to environmental factors like moisture and temperature fluctuations, ensuring long-term performance.

- Eco-Friendly: Graphene-based inks are less toxic and more sustainable than traditional metal-based alternatives.

Applications of GO in Conductive Inks

- RFID Tags: GO-based conductive inks are used to print RFID antennas, enabling seamless integration into product packaging for inventory management and theft prevention.

- Interactive Packaging: Conductive inks enable features like touch-sensitive controls or light-emitting components in packaging, enhancing consumer engagement.

- Smart Cards: GO inks are used in printing circuits for contactless payment cards and ID cards.

- Printed Sensors: GO-based inks enable the creation of low-cost, flexible sensors for detecting environmental conditions, which can be integrated into packaging.

Market Insights

The conductive ink market is expanding rapidly due to the increasing adoption of smart packaging and printed electronics. GO’s versatility and compatibility with printing technologies position it as a valuable material for this growth sector.

Conclusion

Graphene oxide is reshaping the printing and packaging industries by enabling smart labels and conductive inks that combine functionality, sustainability, and affordability. From tracking products in real time to creating interactive packaging that engages consumers, GO-based solutions are driving innovation across diverse sectors.

Smart labels powered by GO enhance supply chain efficiency and product security, offering features like environmental sensing and counterfeit prevention. Meanwhile, GO-based conductive inks enable the widespread adoption of printed electronics, reducing costs and improving environmental sustainability.

As businesses continue to prioritize intelligent and eco-friendly packaging solutions, graphene oxide is set to play an integral role in shaping the future of these industries. By leveraging GO’s unique properties, manufacturers can deliver smarter, more connected, and more sustainable packaging solutions to meet the demands of modern commerce and consumer expectations.