Graphene-Reinforced Plastics: Stronger, Lighter, Smarter

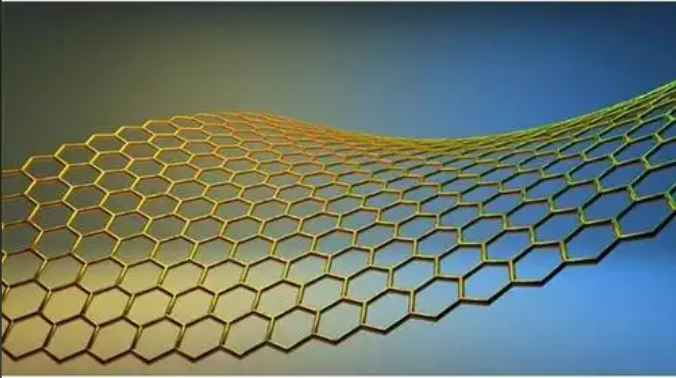

In the quest for stronger, lighter, and multifunctional materials, graphene has become a go-to nanomaterial for reinforcing plastics and polymers. Due to its exceptional mechanical strength, electrical conductivity, and thermal performance, even small amounts of graphene can dramatically enhance the properties of conventional plastics, unlocking opportunities in automotive, aerospace, electronics, and consumer goods.

This article explores how graphene-reinforced polymers (GRPs) are reshaping the performance standards of modern composites.

🔹 1. Why Reinforce Plastics with Graphene?

Traditional polymers like polypropylene (PP), polyethylene (PE), nylon, or polystyrene are low-cost and easy to mold, but they suffer from:

-

Low mechanical strength

-

Poor thermal stability

-

Limited electrical or barrier properties

Graphene, as a 2D nanosheet, offers:

-

High surface area (~2630 m²/g)

-

Tensile strength ~130 GPa

-

Thermal conductivity >5000 W/m·K

-

Electrical conductivity that bridges insulating matrices

🔹 2. Mechanical Reinforcement: Lighter, Yet Stronger

Adding just 0.5–2 wt% of graphene or graphene oxide can:

-

Increase tensile strength by up to 40%

-

Improve Young’s modulus and fracture toughness

-

Enhance impact resistance without added weight

Applications:

-

Automotive interiors and under-hood parts

-

Sporting equipment (e.g., helmets, rackets)

-

Structural panels in drones and consumer electronics

✅ Example: Nylon-6/graphene nanocomposites show >30% improvement in tensile strength with only 1 wt% loading.

🔹 3. Electrical and EMI Shielding Properties

Plastics are traditionally insulators. With graphene:

-

Achieve percolation threshold at low filler content

-

Enable static dissipation in electronics housings

-

Shield devices from electromagnetic interference (EMI)

Graphene-polycarbonate composites are being used in:

-

Laptop and mobile phone casings

-

Automotive electronic control units

-

RFID and antenna enclosures

🔹 4. Thermal Conductivity: Managing Heat

Graphene improves heat dissipation in:

-

LED lighting modules

-

Battery casings and laptop components

-

3D printing filaments for heat-resistant parts

Unlike carbon black or graphite, graphene works at lower loadings, maintaining plastic processability.

🔹 5. Barrier Properties and Chemical Resistance

Graphene sheets form a tortuous path for gas or vapor molecules, improving:

-

Oxygen and moisture resistance

-

Chemical inertness for packaging

-

UV and solvent resistance

Widely used in:

-

Food packaging to extend shelf life

-

Corrosion-resistant coatings

-

Medical containers

🔹 6. Processing Challenges and Solutions

Dispersing graphene uniformly in polymer matrices is essential.

Techniques include:

-

Melt compounding

-

Solvent-assisted blending

-

In-situ polymerization

-

Use of masterbatches or functionalized graphene

Recent advances focus on:

-

Graphene oxide compatibility with polar matrices

-

Thermally reduced GO (rGO) for conductivity

-

3D-printable graphene-polymer filaments

Graphene-reinforced plastics represent a new class of advanced composites with superior performance and tunable functionality. As manufacturing techniques improve, these materials are likely to become mainstream across multiple industries—from automotive to aerospace, electronics to packaging—delivering sustainability through strength, lightness, and durability.