Graphene Slurry for Battery Manufacturing – A Complete Beginner’s Guide

Graphene slurry has rapidly become a key enabling technology in advanced lithium-ion, solid-state, and next-generation batteries. By leveraging graphene’s exceptional conductivity, mechanical strength, and ion transport properties, battery manufacturers can significantly improve charge rate, energy density, and safety performance — without changing existing production lines.

This beginner-friendly guide explains:

✅ What graphene slurry is

✅ Types of graphene slurry

✅ How it is used in cathode & anode manufacturing

✅ Key performance advantages

✅ Selection, purchasing & quality control tips

✅ 2025 market outlook

Whether you are a battery researcher, EV supplier, or energy-storage manufacturer, this guide will help you understand why graphene slurry is becoming the new industry standard.

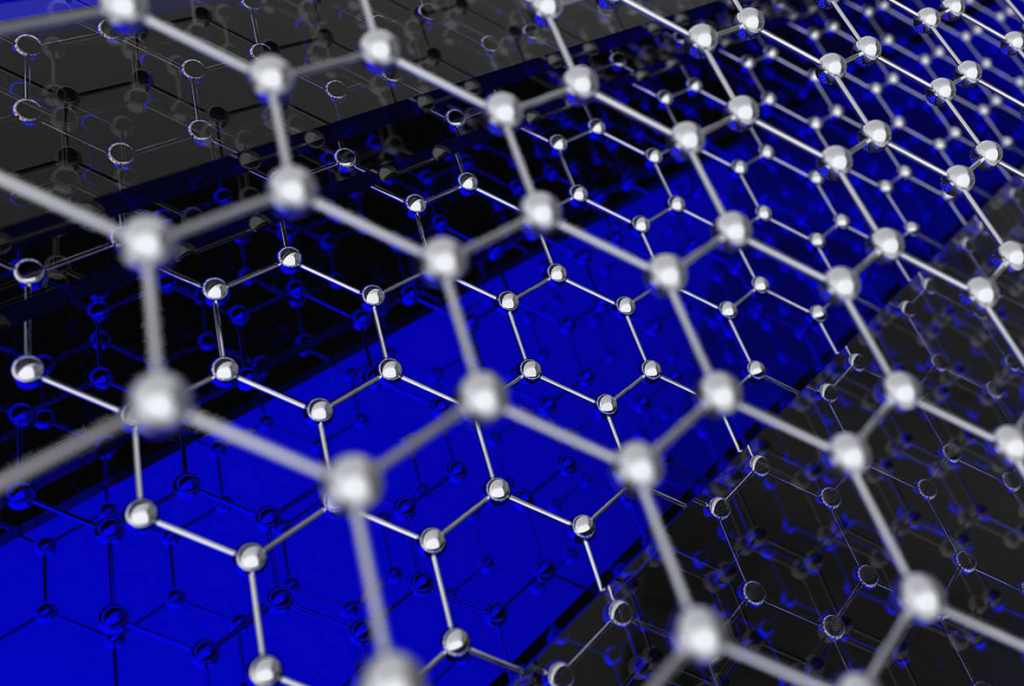

What is Graphene Slurry?

Graphene slurry is a stable, high-concentration dispersion of graphene or graphene derivatives in a liquid medium (typically water or organic solvent). It is specifically engineered for slurry-coating processes used in battery electrode manufacturing.

A typical graphene slurry consists of:

| Component | Function |

|---|---|

| Graphene / Graphene Oxide / Reduced Graphene Oxide | Conductive & mechanical enhancement |

| Binder (PVDF, SBR/CMC, PAA, etc.) | Adhesion to copper/aluminum foil |

| Solvent (NMP / water) | Slurry viscosity & rheology control |

| Additives | Ion diffusion & SEI stability improvements |

Graphene flakes create 3D conductive pathways inside the electrode structure → faster lithium ion movement and stronger structural stability during cycling.

Types of Graphene Slurry

| Type | Base Material | Main Industry Use |

|---|---|---|

| Graphene Oxide Slurry (GO) | Oxidized graphene | Enhanced bonding & dispersion |

| Reduced Graphene Oxide Slurry (rGO) | Conductive restored graphene | High-power batteries |

| Graphene Flake Slurry | Few-layer graphene | EVs, fast-charging cells |

| Hybrid Graphene-Carbon Slurry | CNTs + graphene | Ultra-low resistance electrodes |

GO provides ideal coating uniformity, while rGO and graphene flakes deliver top-tier conductivity.

Why Graphene Slurry for Batteries?

🔋 Major Performance Improvements

| Performance Metric | Traditional Carbon | Graphene-Enhanced | Improvement |

|---|---|---|---|

| Electrical Conductivity | 1× | 6–10× | Faster charge/discharge |

| Ion Transport Efficiency | Low–medium | High | Better high-rate capacity |

| Structural Durability | Limited | Excellent | Long cycle life |

| Electrode Thickness | Hard to reduce | Ultra-thin capable | Higher energy density |

| Safety (swelling/thermal runaway) | Medium risk | Reduced risk | Safer operation |

This allows thinner, lighter, faster-charging electrodes → ideal for EVs and fast-charge consumer electronics.

Applications in Electrode Production

| Battery Component | Function of Graphene Slurry |

|---|---|

| Cathode (NCM, LFP, LMFP) | Improves conductivity & rate performance |

| Anode (Graphite, Si-alloy) | Enhances SEI stability & charging speed |

| Semi-solid / Solid-state | Ensures ion/electron dual-path transport |

| Lithium-sulfur / Metal-air | Suppresses polysulfide shuttling |

Graphene does not replace active materials — it super-charges them.

How to Select the Right Graphene Slurry

✅ Target application: EV? ESS? Consumer electronics?

✅ Conductivity requirement

✅ Viscosity & solid content fit for your coating process

✅ Binder compatibility

✅ Cost vs. performance tradeoff

Recommended Specs (Typical Ranges)

| Parameter | Typical Value |

|---|---|

| Graphene content | 5–20 wt% |

| Slurry viscosity | 1000–8000 cps |

| D50 particle size | < 5 μm |

| Sheet resistance | < 10 Ω/sq (dry film) |

| Solid content | 20–50% |

Production & Quality Control Checklist

| Item | What Matters |

|---|---|

| Dispersion stability | No precipitation ≥ 30 days |

| Defect control | Low oxygen for conductivity |

| Purity | < 0.1% metal contamination |

| Scalability | Supply for GWh-level factories |

| Regulatory compliance | RoHS, REACH, MSDS available |

Cost & Market Opportunities (2025–2030)

-

EV battery demand will achieve 30% CAGR through 2030

-

Graphene-modified electrodes expected in >40% of fast-charging cells

-

Battery producers looking for drop-in upgrades (no line rebuild)

Graphene slurry = high-margin consumable → recurring revenue stream.

Graphene slurry transforms existing electrode designs into faster-charging, higher-density and safer batteries — without costly equipment changes.

✅ Ready for mass production

✅ Customizable for all major chemistries

✅ Ideal for EV, ESS, and premium devices

📩 Contact us for:

• Free technical evaluation

• Datasheet & pricing

• Sample orders and production collaboration

→ Start Your Graphene-Enhanced Battery Project Todayhttps://graphenerich.com/about-us/contact-us/