Graphene Transparent Conductive Films – Competing with ITO

Transparent conductive films (TCFs) are critical components in displays, touch panels, solar cells, smart windows, sensors, and emerging flexible electronics. For over a decade, indium tin oxide (ITO) has been the industry standard due to its high transparency and excellent conductivity. However, ITO suffers from several fundamental limitations: it is brittle, expensive to process on flexible substrates, and dependent on indium—a scarce and volatile material.

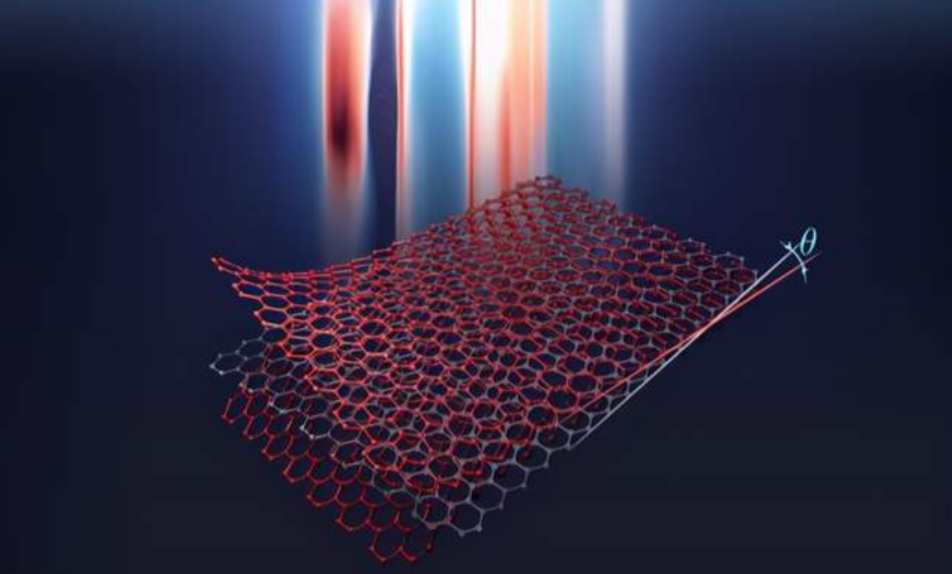

In contrast, graphene transparent conductive films (G-TCFs) offer a new pathway toward lightweight, flexible, and durable electronics. With outstanding mechanical properties, chemical stability, and compatibility with roll-to-roll manufacturing, graphene is becoming a serious competitor to ITO.

This article breaks down how graphene TCFs are produced, how their performance compares with ITO, and where they are already replacing traditional materials in commercial and industrial applications.

1. Why Transparent Conductive Films Are Important

Transparent conductive films serve two primary functions:

-

Conductive pathways for driving pixels, sensing touch, or collecting current

-

Optically transparent windows that maintain high light transmittance

Key performance targets include:

-

Low sheet resistance (Rs)

-

High optical transmittance (T%)

-

Mechanical flexibility

-

Environmental stability

-

Cost-effective scalability

ITO performs well in conductivity and transparency but fails in mechanical durability and flexibility—areas where graphene excels.

2. Limitations of ITO in Modern Electronics

ITO has several critical drawbacks:

2.1 Brittleness

ITO cracks easily under bending or deformation.

In flexible displays, foldable screens, and wearable devices, ITO can only withstand:

-

1–2% strain before failure

-

often <100 bending cycles before cracks appear

2.2 Indium Cost and Scarcity

Indium availability fluctuates significantly due to mining limitations. This impacts:

-

Price stability

-

Manufacturing cost

-

Supply chain risk

2.3 Processing Temperature

ITO typically requires high-temperature deposition (>300°C), incompatible with:

-

PET

-

PEN

-

TPU

-

Other flexible substrates

2.4 Poor Environmental Resistance

ITO suffers degradation under:

-

Bending

-

Impact

-

Moisture

-

Acid/base environments

As electronics increasingly move toward flexible and wearable formats, ITO’s limitations become clear.

3. Why Graphene Is a Strong Alternative to ITO

Graphene’s unique properties make it a compelling TCF material:

3.1 Exceptional Mechanical Flexibility

Graphene withstands:

-

20–25% strain (vs. ITO’s ~2%)

-

Millions of bending cycles with minimal resistance change

This allows unlimited folding and rolling.

3.2 High Conductivity and Transparency

Single-layer graphene achieves:

-

97–98% transparency

-

Sheet resistance <300–600 Ω/sq (single layer)

-

<30 Ω/sq (multi-layer + doping)

These values continue to improve as production methods evolve.

3.3 Ultra-Thin and Lightweight

Graphene is one atom thick (0.34 nm).

Integrating graphene does not alter:

-

Device thickness

-

Mechanical stiffness

-

Optical clarity

3.4 Chemical and Environmental Stability

Graphene is resistant to:

-

Moisture

-

Corrosion

-

UV

-

Acidic/alkaline conditions

Unlike ITO, graphene does not crack or oxidize.

3.5 Compatible with Flexible and Roll-to-Roll Production

Graphene films can be produced using:

-

Continuous CVD processes

-

Laser patterning

-

Wet-transfer techniques

-

Large-area coating

Lower production cost is possible at high volumes.

4. How Graphene Transparent Conductive Films Are Produced

4.1 CVD Graphene on Copper

The most common method.

Process:

-

Grow single/multi-layer graphene on copper foil

-

Coat with protective polymer (PMMA or similar)

-

Etch or peel copper

-

Transfer graphene onto glass/PET/PI

-

Clean, anneal, and dope the film

Advantages:

-

High quality

-

High transparency

-

Continuous large-area production possible

4.2 Roll-to-Roll Transfer

Used for mass manufacturing.

-

Graphene grown on copper foil rolls

-

Transferred onto target films in continuous lines

-

Extremely scalable

-

Ideal for touch panels and flexible displays

4.3 Reduced Graphene Oxide (rGO) Films

Lower cost but lower performance.

Useful for:

-

Sensors

-

Heaters

-

Anti-static layers

-

Smart packaging

4.4 Graphene Composite Films

Graphene + silver nanowires (AgNW)

Graphene + CNT hybrid films

These hybrids combine:

-

Graphene’s mechanical flexibility

-

AgNW or CNT’s conductivity

Result: lower Rs with high flexibility.

5. Performance Comparison: Graphene vs. ITO

Although no table was requested, here is a text-only comparison to stay SEO-friendly.

Conductivity

-

ITO: Very low Rs (10–20 Ω/sq) on glass

-

Graphene: 30–300 Ω/sq depending on layers/doping

-

Hybrid graphene films: 10–30 Ω/sq achievable

Transparency

-

ITO: 85–90%

-

Graphene: 90–98%

Graphene performs especially well in the near-infrared range (important for optical sensors and solar cells).

Mechanical Flexibility

-

ITO cracks easily

-

Graphene withstands extreme bending

Graphene is the clear winner for flexible applications.

Durability

-

ITO degrades under bending, moisture, and impact

-

Graphene maintains stable performance for millions of cycles

This is critical for wearables and rollable displays.

Cost & Scalability

-

ITO relies on rare indium

-

Graphene is carbon-based and scalable via roll-to-roll CVD

Graphene has long-term cost advantages.

6. Applications Where Graphene Is Already Replacing ITO

6.1 Flexible Touch Panels

Graphene films are used in:

-

Foldable phones

-

Curved displays

-

Smart cards

-

E-paper readers

-

Wearable devices

Advantages include bending stability, anti-cracking, and long lifetime.

6.2 Flexible OLED and MicroLED Displays

Graphene films improve:

-

Device bending radius

-

Optical clarity

-

Lifespan under mechanical fatigue

6.3 Transparent Heaters

Graphene TCF heaters are used for:

-

Anti-fog car windows

-

Smart mirrors

-

Display de-icing

-

Optical device heating

Graphene is ideal for high-uniformity transparent heaters.

6.4 Electromagnetic Shielding & Static Dissipation

Used in:

-

Aerospace windows

-

Touch screens

-

Sensor covers

-

Display modules

Graphene provides EMI shielding at ultra-low thickness.

6.5 Solar Cells and Energy Devices

Graphene films enable:

-

Flexible PV modules

-

Perovskite solar cells

-

Transparent electrodes for storage devices

Their transparency and durability are key advantages.

6.6 Smart Windows

Graphene is being used in:

-

Electrochromic windows

-

Smart glass

-

Building-integrated sensors

-

Transparent heating for anti-frost

This reduces maintenance and improves uniformity.

7. Challenges & Engineering Considerations

Although promising, graphene TCF adoption requires careful engineering.

7.1 Sheet Resistance Optimization

Graphene often needs:

-

Multiple layers

-

Chemical doping

-

Hybrid structures (AgNW, CNT, metal grids)

to reach ITO-level conductivity.

7.2 Transfer Quality

Wrinkles, cracks, and contamination during transfer can affect performance.

7.3 Patterning

Laser patterning is preferred for:

-

High precision

-

No chemical waste

-

Fast processing

7.4 Substrate Bonding

Surface treatment improves adhesion to glass, PET, PI, etc.

7.5 Environmental Stability

While graphene is stable, dopants used for conductivity tuning may require encapsulation.

8. Future Outlook – Will Graphene Replace ITO?

Graphene may not fully replace ITO in all applications immediately, but it is already taking significant market share in:

-

Flexible devices

-

Wearables

-

Transparent heaters

-

Anti-static coatings

-

Emerging display technologies

-

Solar cells

-

Automotive windows

As roll-to-roll CVD production matures, graphene’s advantages in flexibility, durability, and cost will become even more compelling.

In the long term, hybrid materials (graphene + metal nanowires + CNTs) will likely become the dominant solution for flexible transparent electronics—offering conductivity that matches or exceeds ITO with far superior mechanical properties.

Graphene transparent conductive films are rapidly emerging as a competitive and scalable alternative to ITO, particularly in flexible and next-generation electronics. With high transparency, strong conductivity, excellent mechanical performance, and compatibility with roll-to-roll manufacturing, graphene is well-positioned to reshape the TCF industry.

For manufacturers of displays, touch panels, smart windows, heaters, and solar cells, graphene films offer a forward-looking solution that aligns with the growing demand for lightweight, flexible, and durable materials.