Graphene vs. Carbon Nanotubes: Which One is Better for You?

Choosing between graphene and carbon nanotubes (CNTs) can be challenging, but understanding their unique properties and applications can help you make an informed decision. Both materials offer remarkable strengths, and the choice depends largely on your specific needs. Let’s delve into their differences and help you determine which one suits your project best.

What is Graphene?

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. It is known for its exceptional electrical conductivity, mechanical strength, and thermal properties. Due to these attributes, graphene is often used in a variety of advanced applications, such as electronics, energy storage, and composites.

Graphene is remarkably light and thin yet incredibly strong. It is 100 times stronger than steel, while also being extremely flexible, making it ideal for applications that require both durability and adaptability. Its ability to conduct electricity and heat efficiently makes it valuable in areas like flexible electronics, sensors, and energy storage devices, such as batteries and supercapacitors.

What are Carbon Nanotubes?

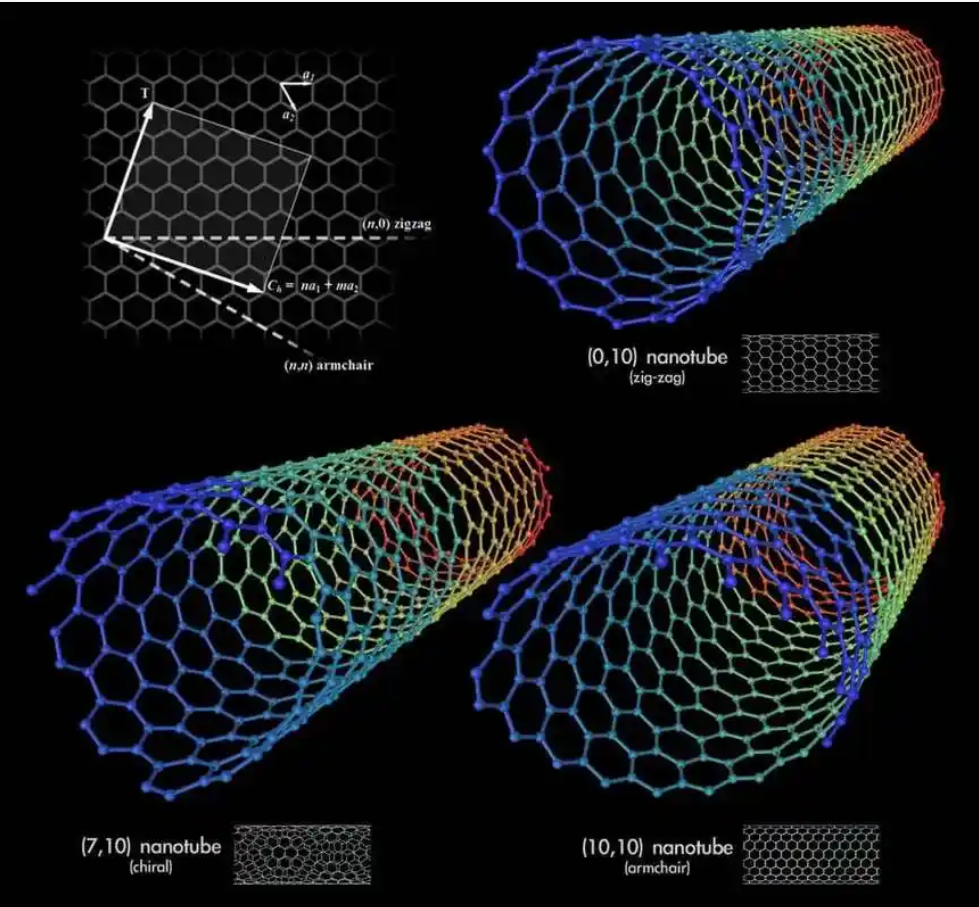

Carbon nanotubes (CNTs) are cylindrical structures made of rolled-up graphene sheets. These tubes can be single-walled (SWCNT) or multi-walled (MWCNT), and their properties are heavily influenced by their structure. CNTs possess remarkable mechanical strength, electrical conductivity, and thermal conductivity, similar to graphene but with some added advantages due to their tubular form.

CNTs are highly effective in reinforcing materials, offering superior strength-to-weight ratios. These properties make them useful in industries ranging from aerospace to electronics. CNTs are also highly efficient conductors of electricity, often used in nanoelectronics and energy storage devices. Their unique structure allows them to be tailored for specific applications, such as drug delivery systems in biomedicine or as a conductive material in composite materials.

Graphene vs. Carbon Nanotubes: What is the Main Difference?

Understanding the primary differences between graphene and carbon nanotubes is crucial in selecting the right material for your project. Let’s compare these two materials in key areas.

Structure and Form

- Graphene: A single layer of carbon atoms arranged in a 2D lattice.

- Carbon Nanotubes: A rolled-up form of graphene, available in single or multi-walled configurations, creating a cylindrical shape.

Electrical and Thermal Properties

- Graphene: Known for its superior electrical and thermal conductivity, graphene excels in applications requiring efficient heat dissipation or high-speed electrical signals.

- Carbon Nanotubes: CNTs also exhibit high electrical and thermal conductivity but often have even higher conductivity in certain configurations, particularly when aligned in bundles. Their tubular structure enhances their performance in specific applications like interconnects in nanotechnology.

Mechanical Strength

- Graphene: Extremely strong, about 100 times stronger than steel, with remarkable flexibility.

- Carbon Nanotubes: CNTs are also incredibly strong and exhibit superior tensile strength due to their cylindrical shape, which enhances their load-bearing capacity, making them ideal for reinforcement in materials.

Versatility and Applications

- Graphene: Its applications are vast, ranging from energy storage, transparent conductive films, and flexible electronics to biomedicine and water filtration. Its versatility in 2D form makes it suitable for numerous fields.

- Carbon Nanotubes: CNTs are used in areas requiring high-strength materials and conductivity, including aerospace, electronics, and biomedical applications. They are often integrated into composite materials or used for energy storage, sensors, and drug delivery systems.

How to Choose Between Graphene and Carbon Nanotubes for Your Project?

Selecting the right material depends on your specific application, desired properties, and performance requirements.

Consider the Form Factor

- Graphene: Ideal for applications where a flat, thin sheet is needed, such as in flexible electronics, conductive films, or coatings.

- Carbon Nanotubes: Perfect for applications requiring a cylindrical or tubular form, such as reinforcement in composite materials or advanced energy storage devices.

Mechanical Requirements

- Graphene: Offers excellent mechanical strength, but when it comes to reinforcing bulk materials, CNTs may provide better results due to their inherent strength in the tubular form.

- Carbon Nanotubes: If your project requires ultra-lightweight yet extremely strong materials, CNTs excel in reinforcing materials while maintaining their strength.

Electrical and Thermal Efficiency

- Graphene: If high conductivity in a flat material is needed, graphene is the better choice, especially in electronics or energy storage applications.

- Carbon Nanotubes: If your application requires the alignment of conductive structures at the nano-scale, CNTs might offer better results, especially in nanoelectronics or energy-efficient devices.

Cost and Manufacturing

- Graphene: Generally easier and more cost-effective to produce in large quantities, but producing defect-free graphene at high yields can still be a challenge.

- Carbon Nanotubes: CNTs are often more difficult and expensive to produce, especially in high-quality, aligned forms. However, their exceptional properties can justify the cost in high-end applications.

Applications of Graphene vs. Carbon Nanotubes

Both graphene and CNTs are used in a variety of cutting-edge industries. Here are some applications where each material shines:

Applications of Graphene

- Electronics and Sensors: Graphene is often used in transistors, sensors, and displays, particularly for its flexibility and conductivity.

- Energy Storage: Graphene is widely applied in supercapacitors and batteries, enhancing their charge and discharge rates.

- Composites: Graphene is integrated into materials to increase strength and conductivity, often used in lightweight, high-performance composites for aerospace and automotive industries.

- Biomedicine: Due to its biocompatibility, graphene is used in drug delivery systems and medical sensors.

Applications of Carbon Nanotubes

- Composite Materials: CNTs are frequently used in materials to enhance mechanical strength, particularly in automotive, aerospace, and sporting goods.

- Nanoelectronics: CNTs are integral in the development of ultra-small transistors and interconnects for next-generation electronics.

- Energy Storage: CNTs are used in batteries and supercapacitors to improve energy density and charge times.

- Biomedicine: CNTs serve as drug delivery carriers, and their large surface area allows for targeted therapy in cancer treatment.

Graphene vs. Carbon Nanotubes: Pros and Cons

| Property | Graphene | Carbon Nanotubes |

|---|---|---|

| Strength | 100 times stronger than steel | Superior tensile strength, ideal for composites |

| Conductivity | Excellent electrical and thermal conductivity | Higher conductivity, especially when aligned |

| Versatility | Ideal for a wide range of applications, from electronics to composites | Ideal for high-strength, lightweight applications |

| Production Cost | Generally lower cost, but scalability issues remain | Higher cost, especially for high-quality CNTs |

| Application Range | Electronics, energy storage, coatings, composites | Aerospace, electronics, energy storage, biomedicine |

| Form Factor | 2D material (flat) | 1D material (tubular), better for reinforcement |

Conclusion: Choosing the Right Material for Your Project

The choice between graphene and carbon nanotubes depends on your project’s specific needs. Graphene excels in applications requiring flat, highly conductive, and versatile materials, while carbon nanotubes shine in applications demanding high strength, flexibility, and conductivity, especially in composite materials. The decision should be made based on the material’s properties, cost-effectiveness, and the intended application.

Both graphene and CNTs offer exceptional capabilities, but understanding their unique features will help you select the best material for your specific requirements.