High-Conductivity Graphene-Coated PA Yarns for EMI Shielding, Thermal Regulation, and De-Icing

Research Overview

Although applying conductive graphene coatings to commercial yarns holds promise for large-scale production, the durability and conductivity of such yarns often degrade due to coating detachment. In a breakthrough study published in Carbon, a research team led by Professors Haobin Zhang and Zhongzhen Yu from Beijing University of Chemical Technology introduces an interface-enhanced strategy to produce highly conductive, mechanically stable yarns.

This method modifies polyamide (PA) yarns with polyethyleneimine (PEI) to strengthen their interaction with graphene oxide (GO) sheets. The GO is further reduced using hydriodic acid (HI), resulting in yarns with excellent electrical performance. The PA-PEI-rGO yarns retain a conductivity of 5.0 × 10³ S/m even after 20 bending cycles, demonstrating impressive stability for bending, embroidery, sewing, and weaving.

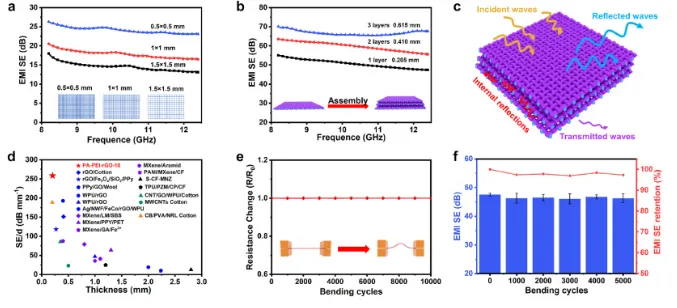

These conductive textiles show outstanding EMI shielding of 66.7 dB at a thickness of 0.615 mm, along with superior hydrophobicity, breathability, and thermal conversion efficiency. Even after 5000 bending cycles, the EMI shielding remains effective, underscoring the yarns’ durability and stability.

Key Visuals and Experimental Results

- Figure 1:

-

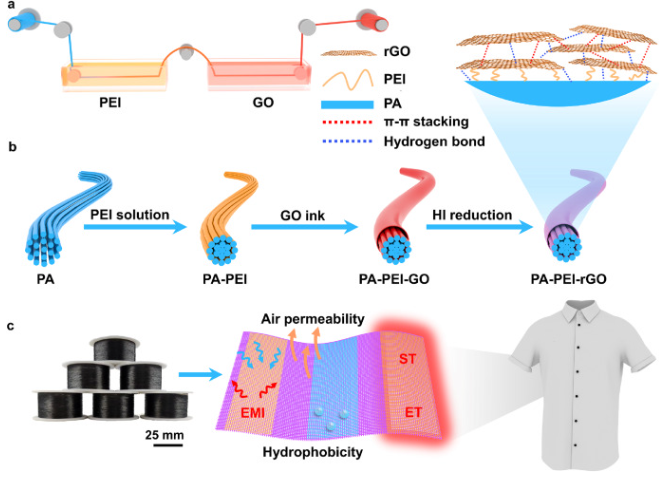

- (a, b) The dip-coating process for PA-PEI-rGO yarns.

- (c) Applications in EMI shielding, electric heating, and solar-thermal conversion.

- Figure 2:

-

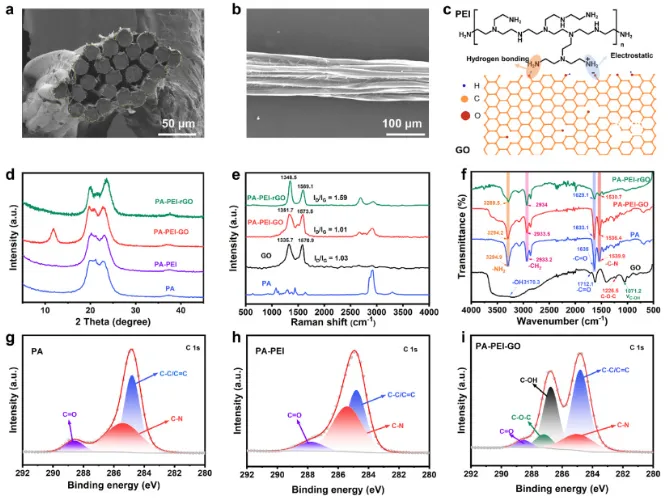

- SEM images showing cross-sections and surfaces of PA-PEI-rGO yarns.

- FT-IR, XRD, and Raman spectra confirming molecular interactions and structure.

- Figure 3:

-

- Stress-strain curves comparing PA-PEI-GO and PA-PEI-rGO yarns under various cycles.

- Conductivity retention after bending and comparison with other conductive fibers.

- (f) A demonstration of the yarn lighting an LED under 3V, showcasing its electronic applications.

- Figure 4:

-

- EMI shielding effectiveness at different thicknesses and mesh sizes.

- (c) The EMI shielding mechanism involving reflection, absorption, and multi-scattering within the yarn.

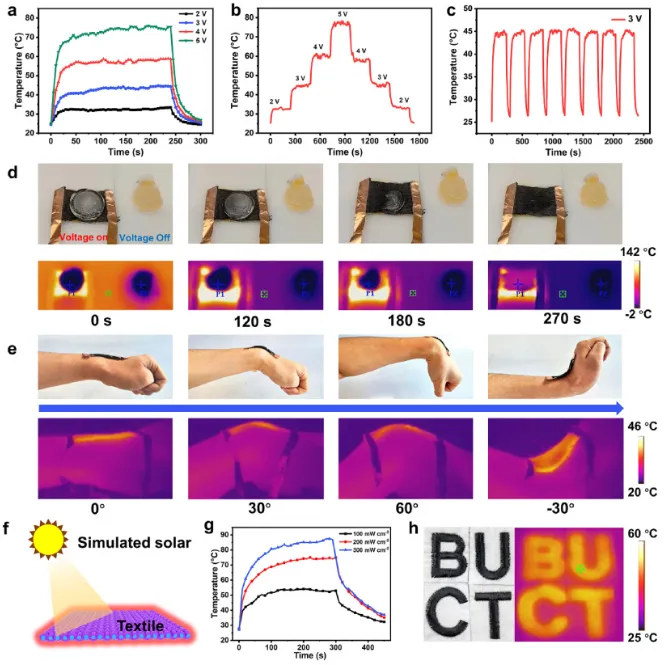

- Figure 5:

-

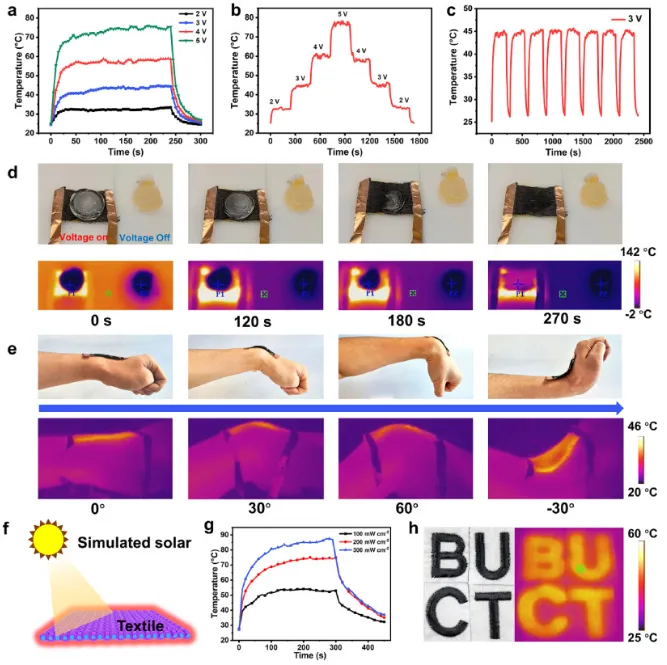

- Thermal performance under varying voltages and solar energy densities.

- Wearable applications: (e) bending tests on the wrist and (d) de-icing in real time.

- (g, h) Solar-thermal response under direct sunlight exposure.

Summary

This work introduces a scalable, cost-effective interface enhancement strategy to produce PA-PEI-rGO yarns with high conductivity for EMI shielding, personal thermal management, and de-icing. By improving the interaction between PEI-modified PA yarns and rGO sheets, these yarns maintain exceptional conductivity and mechanical stability, even after repeated use.

The PA-PEI-rGO textiles achieve 66.7 dB EMI shielding in the X-band and can endure over 5000 bending cycles without performance loss. They offer not only reflection-based EMI protection but also attenuation through multi-scattering and absorption. The conductive yarns excel in solar-thermal conversion, showing potential in wearable electronics, electromagnetic shielding fabrics, and de-icing applications.

Key Features of PA-PEI-rGO Textiles:

- Outstanding EMI shielding: 66.7 dB at 0.615 mm thickness

- Conductivity retention: 5.0 × 10³ S/m after 20 cycles

- Flexible and durable: Withstands 5000 bending cycles

- Excellent thermal performance: Efficient electric heating and solar energy conversion

- Hydrophobic and breathable, suitable for wearable use

This study highlights the significant potential of multifunctional conductive textiles in next-generation electronics and smart clothing, contributing to both practical applications and research in EMI protection and thermal management.

Original Publication: https://doi.org/10.1016/j.carbon.2024.119655