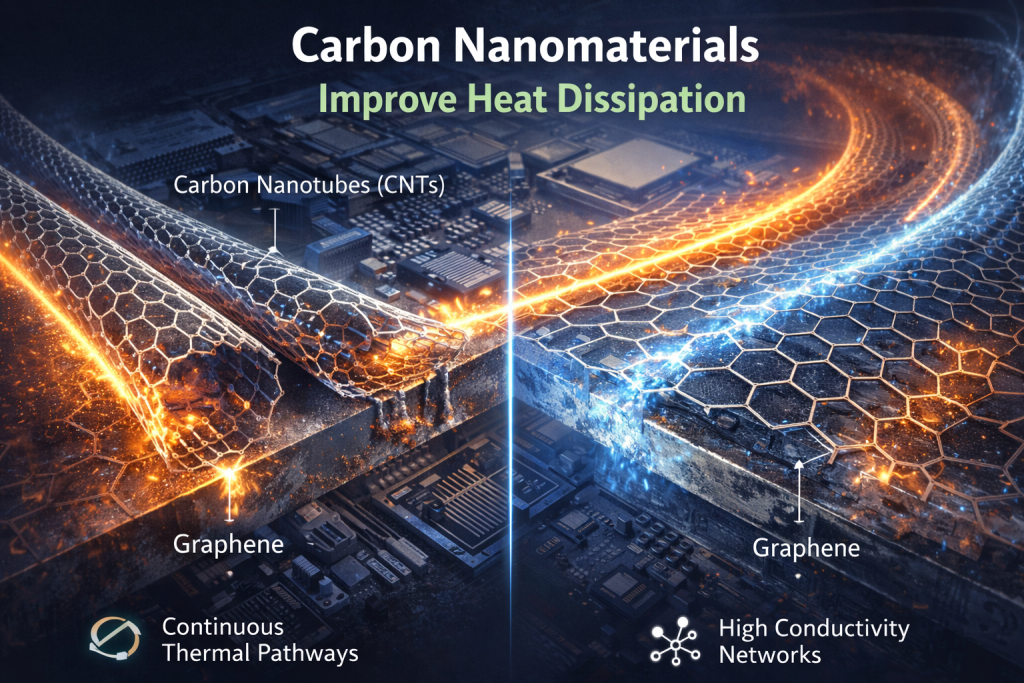

How Carbon Nanomaterials Improve Heat Dissipation

Mechanisms, Material Choices, and Practical Design Insights

Why Heat Dissipation Has Become a Bottleneck

As power density continues to increase across electronics, energy storage, and industrial systems, thermal management has become a primary performance limiter rather than a secondary consideration.

Traditional thermal solutions—metal heat sinks, ceramic fillers, and phase-change materials—are approaching their practical limits. This has driven growing interest in carbon nanomaterials, particularly carbon nanotubes (CNTs) and graphene, as next-generation heat dissipation enhancers.

But how exactly do these materials improve heat dissipation—and what are the real-world design considerations?

What Limits Heat Dissipation in Conventional Materials?

Heat dissipation is governed by several bottlenecks:

-

Low intrinsic thermal conductivity of polymer matrices

-

Poor interfacial contact between filler particles

-

Thermal interface resistance between layers

-

Weight and thickness constraints in compact systems

Traditional fillers such as aluminum oxide or boron nitride improve thermal conductivity, but often require very high loading levels, which negatively impact processability, flexibility, and mechanical integrity.

Why Carbon Nanomaterials Are Different

Carbon nanomaterials stand out due to their unique combination of intrinsic properties and network behavior.

| Material | Intrinsic Thermal Conductivity (theoretical) |

|---|---|

| CNTs | > 3000 W/m·K (along tube axis) |

| Graphene | > 5000 W/m·K (in-plane) |

While these values are rarely achieved at the system level, they explain why even low loadings of carbon nanomaterials can significantly enhance heat dissipation when properly designed.

Mechanism 1: High-Aspect-Ratio Thermal Pathways

Unlike spherical fillers, CNTs and graphene sheets exhibit extremely high aspect ratios.

This enables:

-

Rapid formation of continuous thermal pathways

-

Lower percolation thresholds for heat transport

-

Reduced reliance on particle-to-particle contact

CNTs, in particular, act as one-dimensional heat highways, bridging heat sources and spreading energy across the matrix.

Mechanism 2: Phonon-Dominated Heat Transport

Heat in carbon nanomaterials is primarily carried by phonons rather than free electrons.

This results in:

-

Low phonon scattering along aligned CNTs

-

Efficient in-plane heat spreading in graphene sheets

-

Superior performance in thin films and coatings

When dispersed effectively, these phonon pathways extend into the surrounding matrix, improving bulk heat dissipation.

Mechanism 3: Network Formation at Low Loading Levels

A critical advantage of carbon nanomaterials is their ability to form interconnected thermal networks at very low concentrations.

Typical trends:

-

CNTs: effective thermal enhancement at <1 wt%

-

Graphene: strong in-plane enhancement at 1–5 wt%

Lower loading means:

-

Better mechanical flexibility

-

Easier processing

-

Lower weight penalty

-

Maintained surface quality in coatings and films

CNTs vs Graphene in Heat Dissipation

Although often grouped together, CNTs and graphene play different roles in thermal management.

CNTs excel at:

-

Bridging gaps between interfaces

-

Enhancing through-plane heat transport

-

Improving thermal connectivity in composites

Graphene excels at:

-

In-plane heat spreading

-

Thin-film heat dissipation

-

Coating-based thermal barriers and spreaders

In many applications, hybrid CNT–graphene systems outperform either material alone.

Role of Dispersion and Alignment

Material selection alone does not guarantee performance.

Key design factors include:

-

Degree of dispersion

-

CNT alignment direction

-

Graphene sheet orientation

-

Interfacial bonding with the matrix

Poor dispersion leads to agglomeration, which:

-

Reduces effective thermal pathways

-

Increases thermal resistance

-

Creates mechanical weak points

Controlled dispersion and partial alignment dramatically improve heat dissipation efficiency.

Carbon Nanomaterials in Thermal Coatings

In thermal coatings, carbon nanomaterials offer a unique balance:

-

Thin coating thickness

-

High heat spreading capability

-

Compatibility with metals such as aluminum and steel

Graphene-enhanced coatings are increasingly used to:

-

Improve heat dissipation on heat sinks

-

Reduce surface hot spots

-

Enhance durability under thermal cycling

CNTs contribute by improving interfacial thermal connectivity between coating layers and substrates.

Applications in Thermal Interface Materials (TIMs)

In TIM systems, contact resistance often dominates thermal performance.

Carbon nanomaterials help by:

-

Filling micro-gaps at interfaces

-

Reducing interfacial thermal resistance

-

Maintaining performance under compression and cycling

CNT-based gels, graphene-enhanced pads, and hybrid TIM films are now widely explored for:

-

Power modules

-

Battery systems

-

Data center electronics

Lightweight Heat Dissipation for Energy and Mobility

For EVs, energy storage systems, and portable electronics, weight reduction is as critical as thermal performance.

Carbon nanomaterials enable:

-

Thinner thermal layers

-

Reduced metal mass

-

Integrated multifunctional performance (thermal + electrical)

This makes them particularly attractive for next-generation mobility and renewable energy platforms.

Practical Limitations and Trade-Offs

Despite their advantages, carbon nanomaterials are not a universal solution.

Design challenges include:

-

Cost sensitivity at scale

-

Dispersion consistency in mass production

-

Balancing thermal, electrical, and mechanical properties

-

Process compatibility with existing manufacturing lines

Successful designs focus on system-level optimization, not maximum filler loading.

Testing and Evaluation Considerations

Thermal performance should be evaluated using:

-

In-plane vs through-plane measurements

-

Long-term thermal cycling tests

-

Interface resistance characterization

Lab-scale conductivity values must always be validated under real application conditions.

From Material to Thermal System Design

Carbon nanomaterials improve heat dissipation not simply because they are thermally conductive, but because they enable new thermal architectures.

Their real value lies in:

-

Network formation at low loading

-

Directional heat transport

-

Compatibility with thin, lightweight systems

When properly selected and formulated, CNTs and graphene transform thermal management from a passive constraint into an active design advantage.