🔋 How Carbon Nanotubes Are Transforming Lithium-ion Batteries: A Real-World Case Study

Industry: Energy Storage | Application: EV & High-performance Li-ion Batteries

Material: Multi-walled Carbon Nanotubes (MWCNTs) | Technology: Conductive Additive

🚗 Client Challenge

A leading EV battery manufacturer needed to boost the performance of their NCM-based cathodes. Traditional carbon black additives were limiting:

-

❌ Low electrical conductivity

-

❌ Poor high-rate discharge performance

-

❌ Thicker electrodes leading to reduced energy density

💡 Our CNT-Based Solution

We introduced a custom-dispersed MWCNT conductive paste with high aspect ratio, good NMP compatibility, and optimized particle network formation.

Key Advantages:

✅ High intrinsic conductivity (~10⁴ S/m)

✅ Low dosage (<1%)

✅ Stable dispersion in electrode slurry

✅ Easy integration with current coating lines

📊 Results After 3-Month Testing

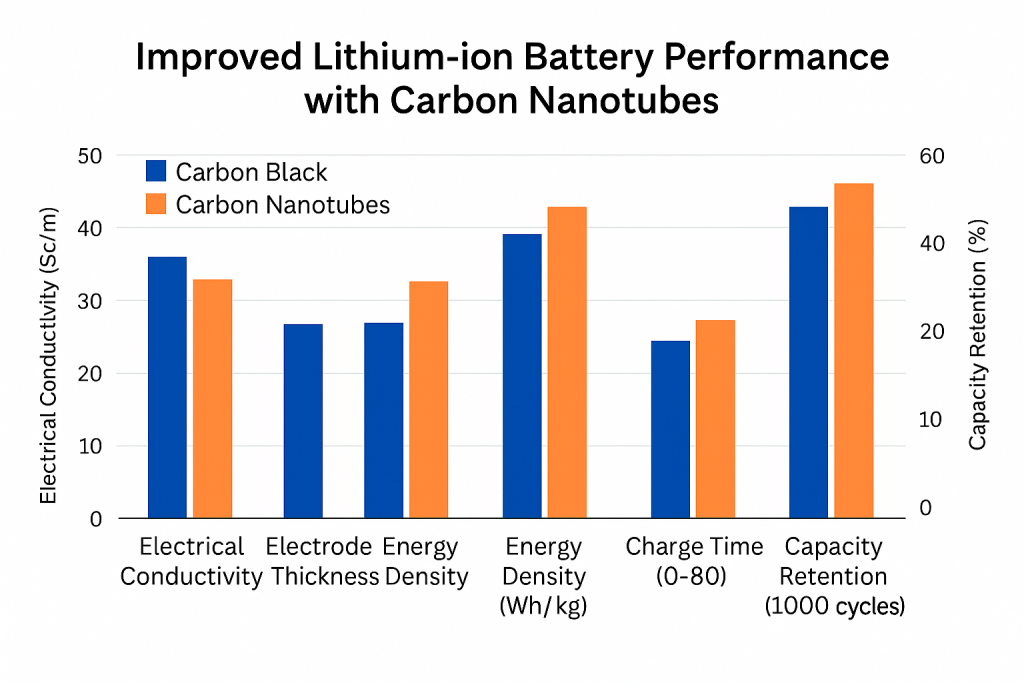

| Parameter | Before (Carbon Black) | After (CNT) | Improvement |

|---|---|---|---|

| Electrical Conductivity (S/cm) | ~20 | ~45 | +125% |

| Electrode Thickness (μm) | 82 | 74 | -10% |

| Energy Density (Wh/kg) | 235 | 254 | +8% |

| Charge Time (0–80%) | 45 min | 30 min | -33% |

| Capacity Retention (1000 cycles) | 84% | 91% | +7% |

🧪 Why It Works

CNTs form an ultra-thin, efficient electron transport network throughout the cathode structure—reducing internal resistance and enabling faster ion mobility.

Unlike spherical carbon black, the 1D tubular geometry of CNTs bridges active material gaps and connects conductive pathways, even at ultra-low dosages.

📸 Visual Summary (Recommended for post image or website banner)

I can generate this image for you upon request.

-

Side-by-side SEM image of CB vs CNT-based electrode (optional)

-

Infographic bar chart comparing conductivity, thickness, and cycle life

-

Captioned image of electrode roll-to-roll line using CNT formulation

📣 Client Feedback

“With CNTs, we didn’t just get better conductivity—we unlocked a new level of fast-charging capability without changing our cathode chemistry.”

— R&D Head, Battery Manufacturer

🌍 What This Means for the Industry

As EV and grid storage applications demand higher energy density, faster charging, and longer life, carbon nanotubes are emerging as a crucial enabler in next-gen battery design.

📩 Interested in trying CNTs for your own battery line?

📞 Reach out: info@graphenerich.com | WhatsApp: +86 13615882924