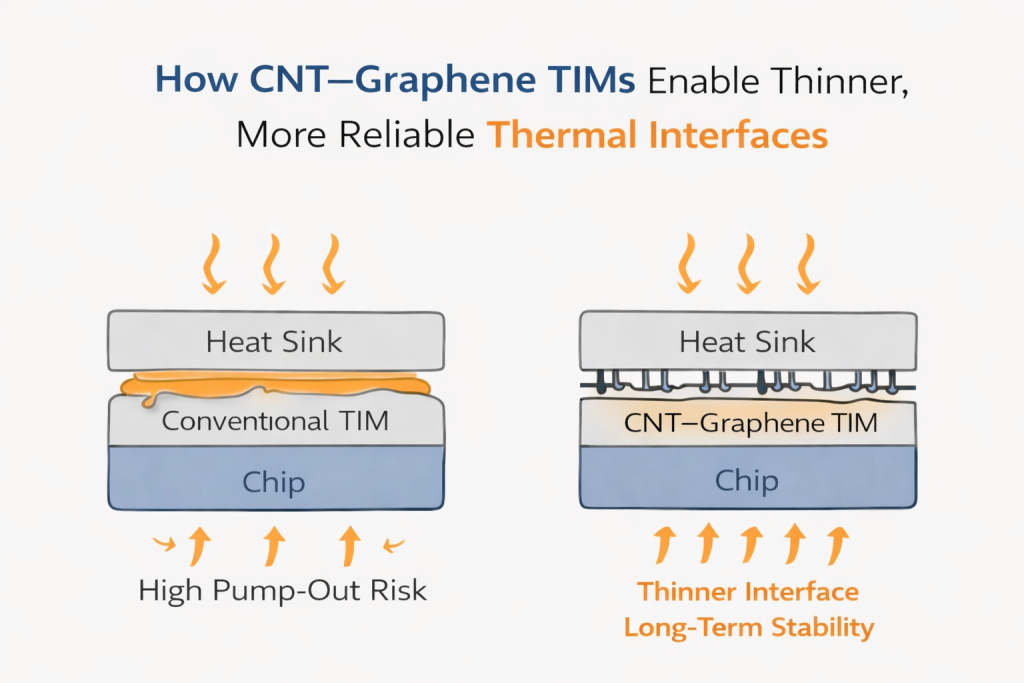

How CNT–Graphene TIMs Enable Thinner, More Reliable Thermal Interfaces

Thinner Interfaces, Higher Expectations

In modern thermal design—especially for battery systems, power electronics, and compact devices—engineers are under increasing pressure to reduce thermal stack thickness while maintaining or improving reliability.

Traditional thermal interface materials often face a trade-off:

-

Thinner bond lines improve heat transfer

-

But thinner layers are more prone to pump-out, dry-out, and contact degradation

CNT–Graphene hybrid TIMs change this balance by enabling ultra-thin interfaces without sacrificing long-term stability.

1. Why Thinner Thermal Interfaces Matter

A thermal interface contributes to total thermal resistance according to:

R=tk+RtcR = \frac{t}{k} + R_{tc}

Where:

-

t = bond line thickness

-

k = bulk thermal conductivity

-

R<sub>tc</sub> = thermal contact resistance

As interfaces become thinner:

-

Bulk resistance decreases

-

Contact resistance dominates system performance

This is where conventional TIMs struggle.

2. The Limitation of Conventional TIMs at Low Thickness

Traditional particle-filled TIMs (metal, alumina, BN):

-

Rely on particle–particle contact

-

Lose conductivity when filler loading is reduced

-

Require high compression to maintain contact

-

Are prone to migration under thermal cycling

At bond lines below ~50 μm, performance degradation becomes significant.

3. CNT–Graphene Hybrid Networks: A Different Heat Transport Model

CNT–Graphene TIMs rely on percolated nano-scale networks rather than random particle packing.

Key structural advantages

-

CNTs bridge gaps between graphene sheets

-

Graphene provides high in-plane heat spreading

-

CNTs enhance through-plane heat transfer

-

Continuous heat pathways form even at low filler loading

This enables effective heat transport at bond lines below 30 μm.

4. Reduced Thermal Contact Resistance at Ultra-Thin Bond Lines

CNT–Graphene TIMs improve interface performance by:

-

Better wetting of micro-asperities

-

Reduced interfacial voids

-

Lower dependence on assembly pressure

-

Stable contact during thermal expansion and contraction

Result:

Lower and more stable R<sub>tc</sub> across thermal cycles

5. Mechanical Compliance Without Pump-Out

One of the biggest challenges in thin TIM layers is pump-out under cycling.

CNT–Graphene systems address this through:

-

Elastic nano-network reinforcement

-

Reduced reliance on low-viscosity base oils

-

Enhanced yield stress at low thickness

This allows:

-

Thin interfaces

-

High vibration resistance

-

Long-term stability without dry-out

6. Reliability Advantages in Real Assemblies

In battery and power electronics applications, CNT–Graphene TIMs demonstrate:

-

Stable thermal impedance after 1,000+ cycles

-

Reduced performance drift

-

Improved resistance to shear and compression fatigue

-

Consistent performance across wide temperature ranges

This makes them particularly suitable for:

-

EV battery cooling plates

-

Power module baseplates

-

High-power inverters and converters

7. Enabling New Thermal Design Freedom

Because CNT–Graphene TIMs remain effective at thin bond lines, engineers gain:

-

Reduced stack height

-

Higher power density

-

Lower mechanical stress

-

Greater tolerance to surface flatness variation

This enables more compact, more reliable system architectures.

8. Design Considerations for Thin CNT–Graphene TIMs

To fully benefit from thin interfaces:

-

Control surface roughness (Ra < 1–2 μm recommended)

-

Optimize CNT/graphene ratio for through-plane transport

-

Match TIM rheology to assembly pressure

-

Validate long-term cycling performance, not just initial conductivity

Thin Interfaces Without Compromise

CNT–Graphene TIMs allow engineers to move beyond the traditional trade-off between:

-

Thin interfaces

-

Long-term reliability

By combining nano-scale thermal pathways with mechanical compliance, these materials enable thinner, more stable, and more reliable thermal interfaces—exactly what next-generation energy and power systems require.