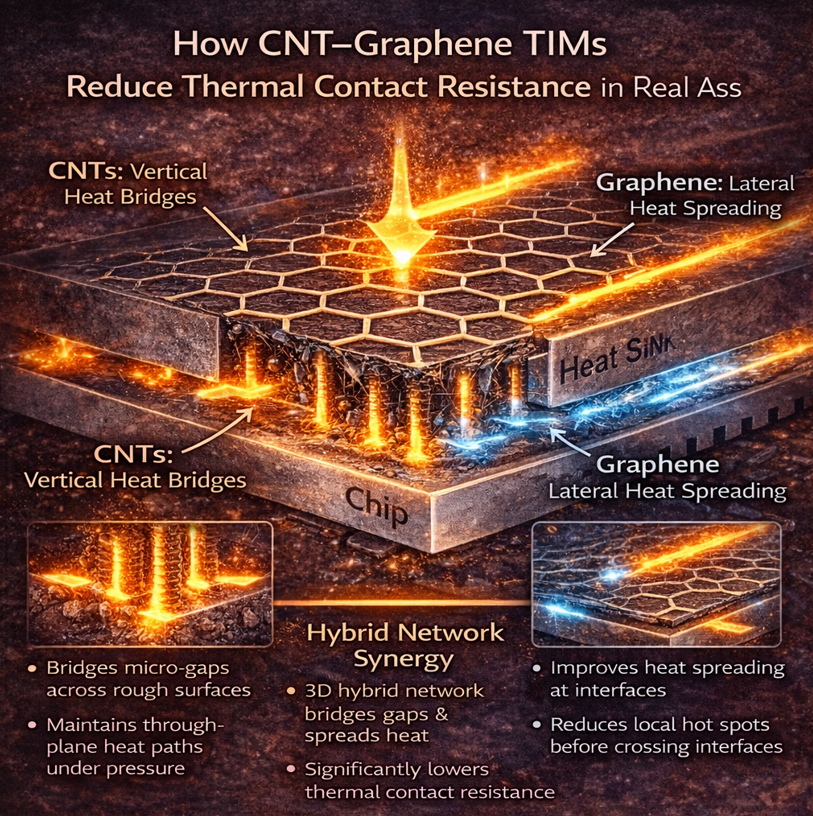

How CNT–Graphene TIMs Reduce Thermal Contact Resistance in Real Assemblies

From Material Properties to Assembly Performance

Thermal Interface Materials (TIMs) are often evaluated by bulk thermal conductivity. However, in real assemblies—where surfaces are rough, pressures are uneven, and thermal cycling is unavoidable—thermal contact resistance (TCR) becomes the dominant factor determining heat dissipation efficiency.

CNT–graphene hybrid TIMs are increasingly adopted not because they offer the highest bulk conductivity, but because they systematically reduce interface resistance under real operating conditions.

Why Real Assemblies Are Different from Lab Conditions

In practical systems, TIMs must operate under:

-

Non-ideal surface roughness

-

Limited or uneven clamping pressure

-

Thermal expansion mismatch

-

Long-term thermal cycling and vibration

Under these conditions, many traditional TIMs fail to maintain effective thermal contact, even if their datasheet conductivity appears high.

The Interface Challenge in Real Assemblies

At the interface between a heat source and a heat sink:

-

Contact occurs only at micro-scale asperities

-

Air pockets form unavoidable thermal barriers

-

Mechanical relaxation over time increases interface gaps

Reducing thermal contact resistance therefore requires both structural conformity and stable thermal pathways—a challenge that particle-filled TIMs struggle to meet.

How CNT–Graphene TIMs Work at the Interface Level

CNTs: Vertical Heat Bridges Across Micro-Gaps

Carbon nanotubes provide:

-

High axial thermal conductivity

-

High aspect ratio for gap bridging

-

Elastic compliance under pressure

In real assemblies, CNTs act as nano-scale thermal springs, maintaining contact across uneven surfaces and ensuring through-plane heat transfer even at low pressure.

Graphene: Lateral Heat Redistribution at the Interface

Graphene sheets deliver:

-

Exceptional in-plane thermal conductivity

-

Rapid lateral heat spreading

-

Reduction of localized hot spots

Before heat crosses the interface, graphene distributes thermal energy across a wider area, reducing thermal bottlenecks at individual contact points.

Hybrid Network Synergy

When combined:

-

CNTs connect graphene sheets vertically

-

Graphene spreads heat laterally

-

The hybrid network forms a continuous 3D thermal pathway

This structure reduces dependence on perfect surface contact and significantly lowers effective thermal contact resistance.

Performance Advantages in Real Assemblies

Lower Pressure Dependence

Traditional TIMs often require high clamping force to achieve acceptable contact resistance. CNT–graphene TIMs maintain performance under:

-

Lower assembly pressure

-

Uneven mechanical loading

This is critical for delicate components and lightweight assemblies.

Improved Stability Under Thermal Cycling

Thermal cycling causes expansion, contraction, and material fatigue. Hybrid CNT–graphene networks:

-

Accommodate mechanical movement

-

Maintain conductive pathways

-

Reduce performance degradation over time

Reduced Pump-Out and Dry-Out Risks

CNT–graphene networks enhance internal cohesion within the TIM, improving resistance to:

-

Pump-out during vibration

-

Phase separation at elevated temperature

This improves long-term reliability in automotive and industrial environments.

Comparison with Traditional TIM Systems

| Aspect | Traditional Fillers | CNT–Graphene TIMs |

|---|---|---|

| Interface conformity | Limited | Excellent |

| Pressure sensitivity | High | Low |

| Micro-gap bridging | Poor | Strong |

| Thermal cycling stability | Moderate | High |

| Effective TCR reduction | Limited | Significant |

Real-World Application Examples

Battery Modules

-

Uneven surfaces and large interface areas

-

CNT–graphene TIMs improve module-level heat uniformity

Power Electronics

-

Thin bond lines and high heat flux

-

Reduced interface resistance enables higher power density

Industrial Control Systems

-

Long service life under vibration

-

Stable thermal performance over extended cycles

Design Guidelines for Engineers

To fully leverage CNT–graphene TIMs:

-

Optimize CNT-to-graphene ratio for application geometry

-

Control dispersion to avoid agglomeration

-

Match mechanical compliance to interface pressure

-

Evaluate total thermal resistance, not just bulk k-value

Cost vs. Performance Consideration

While CNT–graphene fillers have higher material cost, system-level benefits often include:

-

Lower required filler loading

-

Reduced material thickness

-

Improved reliability and lifetime

This frequently results in better overall ROI.

Interfaces Define Real Thermal Performance

In real assemblies, thermal performance is governed not by idealized material properties, but by how effectively heat crosses imperfect interfaces.

CNT–graphene TIMs address this challenge directly by combining:

-

Vertical heat bridging

-

Lateral heat spreading

-

Mechanical adaptability

The result is lower thermal contact resistance, greater reliability, and more predictable thermal behavior in real-world systems.