How Graphene Anodes Are Powering the Next Generation of Fast-Charging Batteries

In a world driven by mobile energy, the pressure on lithium-ion battery technology is greater than ever. From electric vehicles (EVs) to smartphones, users demand faster charging, higher capacity, and longer lifespan. Traditional graphite anodes are reaching their limits. Enter graphene anodes—the high-speed highway for next-generation fast-charging batteries.

💡 Why Traditional Anodes Fall Short

Graphite, the conventional anode material in lithium-ion batteries, offers decent capacity and cycle life. But its charging rate is inherently limited by lithium-ion diffusion speed and potential for structural degradation. In high-rate charging, graphite anodes are prone to lithium plating and thermal instability.

✨ What Makes Graphene Different?

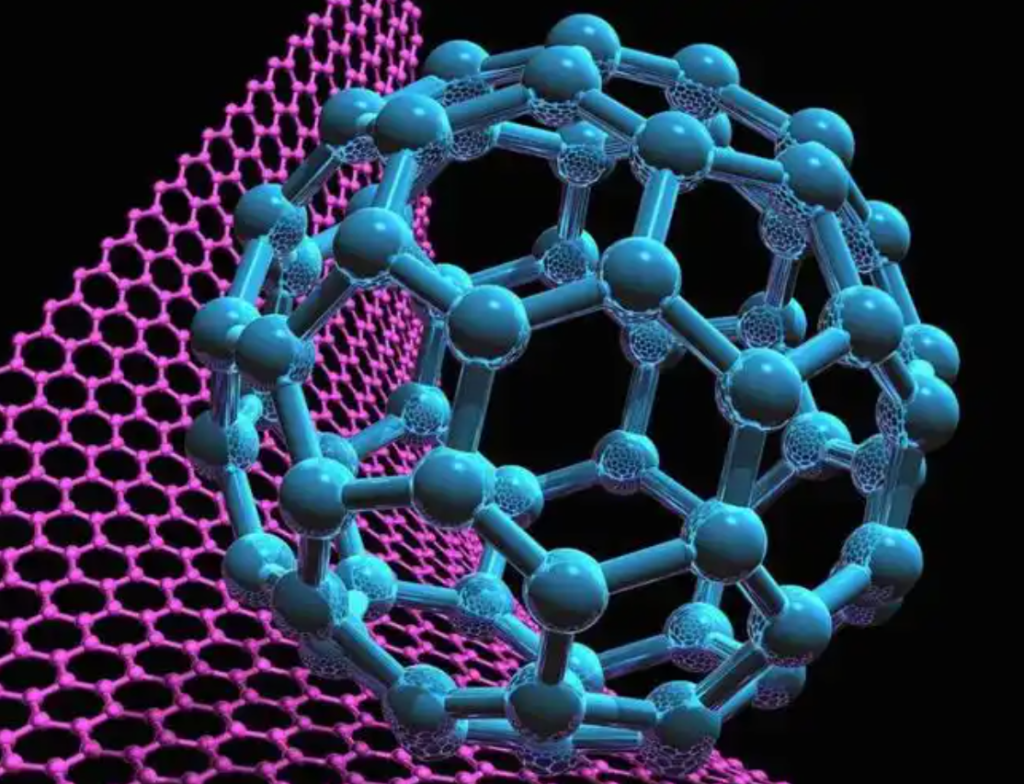

Graphene’s unique properties provide a dramatic performance upgrade:

- High electrical conductivity: 10⁴–10⁵ S/m

- Large surface area: ~2630 m²/g

- Mechanical strength: 200x stronger than steel

- Flexibility and chemical tunability

These characteristics enable faster electron transport and shorter lithium diffusion paths, making graphene-based anodes ideal for rapid charging.

🚗 Real-World Application: EV Fast Charging

Automakers and battery developers are increasingly turning to graphene anode composites (often with silicon or carbon nanotubes) to accelerate charge times:

- Chinese EV battery makers have introduced rGO-silicon composite anodes, achieving 80% charge in under 10 minutes.

- European startups are using graphene aerogel structures to enable ultra-high-rate lithium-ion and sodium-ion systems.

Graphene also enhances thermal stability, critical for safety in fast-charging protocols.

⚖️ GO vs. rGO in Anode Design

Graphene Oxide (GO) is rich in oxygen groups, which can anchor active materials like silicon, but has low conductivity. Reduction to rGO partially restores the conductive network, balancing capacity and conductivity.

Engineered graphene composites can be tailored to:

- Minimize SEI formation

- Maintain structural integrity over 1000+ cycles

- Improve coulombic efficiency (>99.5%)

🔹 Current Challenges

Despite the promise, graphene anodes face hurdles:

- Scalable synthesis: Producing high-quality graphene at industrial scale remains cost-sensitive.

- Material uniformity: Controlling layer number and oxygen content is essential for performance.

- Integration with current manufacturing lines: Needs compatibility with slurry coating, calendaring, and standard electrolyte systems.

🔍 What’s Next? Research & Commercial Trends

- Hybrid carbon systems: Combining graphene with carbon nanotubes or mesoporous carbon for enhanced electron pathways.

- Binder-free electrodes: Using graphene foams or films to eliminate insulating additives.

- AI-optimized formulations: Predictive models to optimize graphene-based anode structures.

At GrapheneRich NanoTech, we offer custom-tailored graphene and rGO powders and dispersions, designed to meet the needs of battery innovators. Our small-particle rGO-CNT hybrid (16 µm, 121 m²/g) is ideal for pre-lithiation or high-rate applications.

🔄 Summary

Graphene anodes are not just a laboratory curiosity—they are becoming the backbone of high-performance, fast-charging batteries. With advances in scalable production, composite design, and integration strategies, graphene is positioned to reshape the energy storage landscape.

As demand surges for clean, high-speed energy solutions, graphene anodes stand at the forefront of the battery revolution.