How Much Do Carbon Nanotubes Cost?

Carbon nanotubes (CNTs) are among the most revolutionary materials discovered in recent decades. These cylindrical structures composed of carbon atoms have remarkable properties, including high tensile strength, excellent electrical conductivity, and impressive thermal stability. They are used in a wide range of industries, from electronics and energy storage to aerospace and healthcare.

If you’re exploring the market for carbon nanotubes, understanding the factors that influence their cost is essential. This article will explain the types of CNTs, their applications, price ranges, and the key factors affecting their cost.

What Are Carbon Nanotubes?

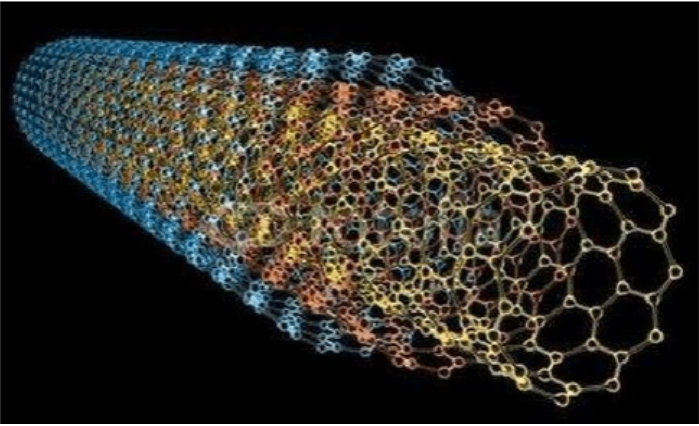

Carbon nanotubes are allotropes of carbon with a cylindrical nanostructure. There are two primary types of CNTs:

- Single-Walled Carbon Nanotubes (SWCNTs): Composed of a single layer of graphene rolled into a tube.

- Applications: Electronics, biomedical devices, and sensors.

- Advantages: High electrical conductivity and exceptional mechanical properties.

- Multi-Walled Carbon Nanotubes (MWCNTs): Made of multiple layers of graphene concentrically wrapped.

- Applications: Structural reinforcement, energy storage, and thermal management.

- Advantages: Higher production yield and lower cost compared to SWCNTs.

How Much Do Carbon Nanotubes Cost?

The price of carbon nanotubes varies depending on their type, quality, and production method. Below is a general breakdown:

Single-Walled Carbon Nanotubes (SWCNTs)

- Price Range: US$100–US$1,000 per gram.

- Key Factors:

- Purity: High-purity SWCNTs are significantly more expensive.

- Functionalization: Adding chemical groups for specific applications increases the cost.

- Production Scale: Laboratory-scale production leads to higher prices.

Multi-Walled Carbon Nanotubes (MWCNTs)

- Price Range: US$10–US$100 per gram.

- Key Factors:

- Diameter: Smaller diameters with fewer defects cost more.

- Functionalization: Modified MWCNTs for enhanced properties are pricier.

- Bulk Quantities: Industrial-scale production makes MWCNTs more affordable.

Factors That Affect Carbon Nanotube Pricing

Several factors contribute to the wide price range of carbon nanotubes:

1. Purity and Quality

Higher-purity CNTs have fewer impurities like metal catalysts or amorphous carbon, making them more suitable for advanced applications such as electronics and medical devices.

2. Production Method

The method used to synthesize CNTs, such as chemical vapor deposition (CVD), arc discharge, or laser ablation, affects the cost. CVD is the most common method for large-scale production due to its relatively lower cost.

3. Functionalization

Functionalized CNTs, which are chemically treated for specific applications, often command higher prices. For example, carboxylated or hydroxylated CNTs are widely used in biomedical and composite applications.

4. Scale of Production

While laboratory-grade CNTs are expensive due to small-scale production, industrial-scale manufacturing significantly reduces costs, especially for MWCNTs.

5. Application-Specific Requirements

Certain industries, such as aerospace and defense, demand highly customized CNTs with specific properties, which increases the overall cost.

Applications of Carbon Nanotubes

1. Electronics and Semiconductors

- CNTs are used to create conductive films, transistors, and sensors. Their superior electrical properties enable faster and smaller electronic devices.

2. Energy Storage

- CNTs enhance the performance of lithium-ion batteries, supercapacitors, and fuel cells by increasing conductivity and improving charge storage capacity.

3. Composite Materials

- CNTs are added to polymers and metals to improve strength, durability, and thermal resistance in industries such as construction and aerospace.

4. Biomedical Applications

- Due to their nanoscale size and functionalization capabilities, CNTs are used in drug delivery systems, imaging, and biosensors.

5. Thermal Management

- CNTs are employed as thermal interface materials (TIMs) in electronics, helping to dissipate heat efficiently.

Popular Carbon Nanotube Products

High-Purity Single-Walled CNTs

- Ideal for electronic and research applications.

- Features: High conductivity, customizable functional groups, and excellent dispersion properties.

Industrial-Grade Multi-Walled CNTs

- Commonly used in composite materials and energy storage.

- Features: Affordable, easy to process, and widely available in bulk.

Additional Costs to Consider

When purchasing carbon nanotubes, additional costs may apply:

- Shipping and Handling

- International shipping for research-grade CNTs can be expensive due to specialized packaging.

- Safety and Handling Equipment

- CNTs require careful handling due to potential health risks from inhalation. Investing in proper safety equipment is essential.

- Processing and Integration

- Costs for dispersion agents, mixing equipment, and post-processing can add up, especially for applications requiring precise integration of CNTs.

Is Buying Carbon Nanotubes Worth It?

The answer depends on your application. For high-performance requirements in industries like aerospace, electronics, or healthcare, investing in premium CNTs is worthwhile. However, for general composite reinforcement or thermal applications, affordable MWCNTs may suffice.

Final Words

Carbon nanotubes offer unparalleled advantages across various industries. While their cost may seem high, their unique properties justify the investment for applications that demand cutting-edge performance.

Before purchasing, consider the type, quality, and scale of CNTs required for your project. By understanding the factors influencing the cost, you can make informed decisions and maximize the benefits of this revolutionary material.

Investing in the right type of CNTs can pave the way for innovative applications and long-term success in your projects.