How to Get Started with Single-Walled Carbon Nanotubes (SWCNTs) – A Beginner’s Guide

You can understand the structure, properties, synthesis, dispersion, and applications of single-walled carbon nanotubes (SWCNTs), as well as how to select, purchase, and handle them in this comprehensive guide for beginners.

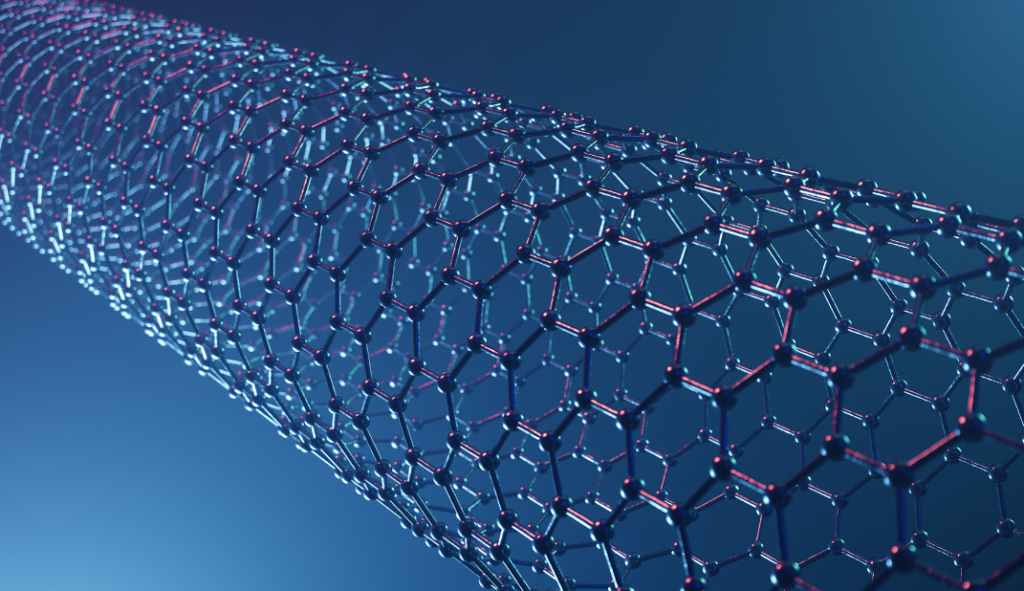

Single-walled carbon nanotubes (SWCNTs) are cylindrical nanostructures made of a single layer of graphene rolled into a seamless tube, typically 0.7–2 nm in diameter and several micrometers in length. Their unique one-dimensional structure gives them exceptional electrical, mechanical, and thermal properties, making SWCNTs one of the most promising nanomaterials for electronics, composites, sensors, and energy storage devices.

The concept of carbon nanotubes was first introduced by Sumio Iijima in 1991, and since then, SWCNTs have evolved from laboratory curiosities to key components in next-generation materials. Due to their quantum-level structure and ballistic electron transport, they can outperform traditional conductive fillers and structural reinforcements in many applications.

Structure and Properties

SWCNTs consist of a graphene sheet rolled into a cylinder defined by its chiral vector, which determines whether the nanotube behaves as a metal or a semiconductor.

-

Diameter: 0.7 – 2 nm

-

Length: up to several micrometers or even millimeters

-

Density: ~1.3–1.4 g/cm³

-

Electrical conductivity: up to 10⁶–10⁷ S/m

-

Thermal conductivity: up to 3500 W/m·K

-

Tensile strength: 30–50 GPa

Because of these extraordinary properties, SWCNTs can be viewed as nanoscale wires or fibers that combine the best aspects of metals and polymers.

Types of SWCNTs

1. Metallic SWCNTs

-

Electrical properties: Conduct electricity like metals due to their chiral structure.

-

Applications: Transparent conductive films, interconnects, antennas, and shielding.

-

Advantages: Extremely low resistivity and high carrier mobility.

2. Semiconducting SWCNTs

-

Electrical properties: Exhibit band gaps of 0.4–1.0 eV, similar to silicon.

-

Applications: Transistors, sensors, and photodetectors.

-

Advantages: Can be used in flexible and transparent electronic circuits.

3. Mixed SWCNTs

-

Composition: Typically as-produced materials contain both metallic and semiconducting tubes.

-

Applications: General conductive additives, composites, and coatings.

-

Note: Separation techniques (e.g., electrophoresis or selective functionalization) can purify specific types.

Synthesis Methods

The production method determines SWCNT quality, purity, and cost. The most common methods are:

1. Chemical Vapor Deposition (CVD)

-

Process: Hydrocarbon gases (e.g., methane, acetylene) are decomposed on metal catalysts (Fe, Co, Ni) at 600–1000°C.

-

Advantages: Scalable, controlled growth, widely used in industry.

-

Applications: Electronics, composites, and thin films.

2. Arc Discharge

-

Process: Carbon atoms are vaporized between graphite electrodes under an inert gas atmosphere.

-

Advantages: High crystallinity, fewer defects.

-

Limitations: Harder to control diameter and purity.

3. Laser Ablation

-

Process: A graphite target containing catalysts is vaporized by a laser beam.

-

Advantages: Produces uniform SWCNTs with excellent structure.

-

Limitations: Expensive and low yield, suitable for research-grade materials.

4. Floating Catalyst / HiPco Process

-

Process: Uses gas-phase iron carbonyl as catalyst in a flowing hydrocarbon stream.

-

Advantages: Produces clean, small-diameter SWCNTs.

-

Applications: High-end electronics and composites.

Dispersion and Functionalization

Raw SWCNTs tend to aggregate due to strong van der Waals forces. To fully utilize their properties, they must be well-dispersed in a solvent or polymer matrix.

Dispersion Techniques

-

Ultrasonication: Breaks aggregates into smaller bundles.

-

Surfactants: SDS, Triton X-100, or SDBS improve water dispersion.

-

Solvents: NMP, DMF, ethanol, or water (with surfactant) are commonly used.

-

Mechanical Mixing: High-shear mixing ensures even distribution in polymers.

Functionalization Methods

-

Covalent: Introduces carboxyl, hydroxyl, or amine groups on tube surfaces to improve compatibility.

-

Non-covalent: Uses polymers or π–π stacking molecules to preserve conductivity.

-

Result: Enhanced solubility, bonding with matrix materials, and surface reactivity.

Applications of SWCNTs

1. Electronics and Conductive Films

SWCNT networks form transparent conductive films used in displays, touch panels, and flexible electronics. They can replace ITO (indium tin oxide) due to their flexibility and low sheet resistance.

2. Composites and Structural Materials

Adding 0.1–1 wt% SWCNTs to polymers or resins significantly enhances mechanical strength, conductivity, and thermal stability. Applications include aerospace panels, sports equipment, and automotive parts.

3. Energy Storage

SWCNTs are used in battery electrodes, supercapacitors, and fuel cells as conductive scaffolds, improving ion diffusion and charge transfer.

4. Sensors

Due to their sensitivity to environmental changes, SWCNTs are used in gas sensors, biosensors, and strain gauges. Semiconducting SWCNTs can detect trace gases at room temperature.

5. Thermal Management

Their high thermal conductivity enables SWCNTs to serve as heat spreaders, thermal interface materials, and composite fillers in electronics.

6. Biomedical Applications

SWCNTs functionalized with biomolecules are applied in drug delivery, bioimaging, and neural interfacing, benefiting from their nanoscale dimensions and surface versatility.

What Should I Consider When Buying SWCNTs?

-

Purity: High-purity SWCNTs (>90%) minimize metallic impurities and improve consistency.

-

Diameter and Length: Smaller diameters enhance surface area, while longer tubes improve conductivity.

-

Form: Powder, dispersion, or masterbatch. Powders are versatile; dispersions save processing time.

-

Metal Content: Residual catalysts (Fe, Co, Ni) should be <5% for most applications.

-

Bundling State: Individual or small-bundle SWCNTs perform better in electronics and coatings.

-

Electrical Type: Choose metallic or semiconducting depending on target use.

-

Supplier Certification: Request Raman, TGA, and TEM data for verification.

-

Price Range (2025):

-

Research-grade: $400–$1200 per gram (ultrapure separated types).

-

Industrial-grade: $200–$800 per kilogram (mixed types for composites).

-

How to Handle and Process SWCNTs Safely

Step 1. Work in a fume hood or ventilated enclosure to prevent inhalation of airborne nanoparticles.

Step 2. Always wear gloves, protective clothing, and an N95 or P100 respirator when handling powders.

Step 3. For dispersions, gently shake or ultrasonicate before use to ensure homogeneity.

Step 4. Avoid strong mechanical grinding, which may shorten or damage the nanotubes.

Step 5. Store SWCNTs in sealed containers in a dry, cool place to prevent oxidation.

Step 6. Dispose of waste following nanomaterial safety and environmental regulations.

Step 7. When mixing with polymers or resins, use gradual shear mixing or solvent-assisted blending to achieve uniform distribution.

Top SWCNT Products You Can Purchase in 2025

#1 NanoTube-S (High-Purity SWCNT Powder)

-

Purity: 95%

-

Diameter: 1.3–1.5 nm

-

Application: Conductive films, transparent electrodes

-

Price: $350–$700/g (research grade)

#2 SWC-Disp™ (Aqueous SWCNT Dispersion)

-

Concentration: 0.5 wt%

-

Surfactant-stabilized, long-term stable solution

-

Ideal for printing and coating processes

-

Price: $180–$350 per 100 mL

#3 SWCNT-MB™ (Polymer Masterbatch)

-

Contains 5 wt% SWCNTs pre-dispersed in thermoplastic matrix

-

Easy integration into composite production lines

-

Application: Automotive, aerospace, and antistatic polymers

-

Price: $250–$500/kg

Comparison: SWCNTs vs Multi-Walled CNTs

| Property | SWCNTs | MWCNTs |

|---|---|---|

| Structure | Single graphene cylinder | Multiple concentric cylinders |

| Diameter | 0.7–2 nm | 5–50 nm |

| Electrical Conductivity | Higher (up to 10⁷ S/m) | Moderate |

| Mechanical Strength | Superior | High but less flexible |

| Surface Area | Larger per gram | Smaller |

| Purity Cost | More expensive | More affordable |

| Applications | Electronics, sensors, transparent films | Bulk composites, coatings, rubbers |

Single-walled carbon nanotubes (SWCNTs) represent the cutting edge of nanomaterials, combining atomic-scale perfection with macroscopic performance. Their unique electrical and mechanical properties have already begun to transform industries—from flexible electronics and high-strength composites to next-generation energy storage.

By understanding how to select, disperse, and apply SWCNTs effectively, you can bridge the gap between laboratory research and industrial innovation.

After reading this guide, are you ready to take your first step from SWCNT beginner to nanotechnology professional?