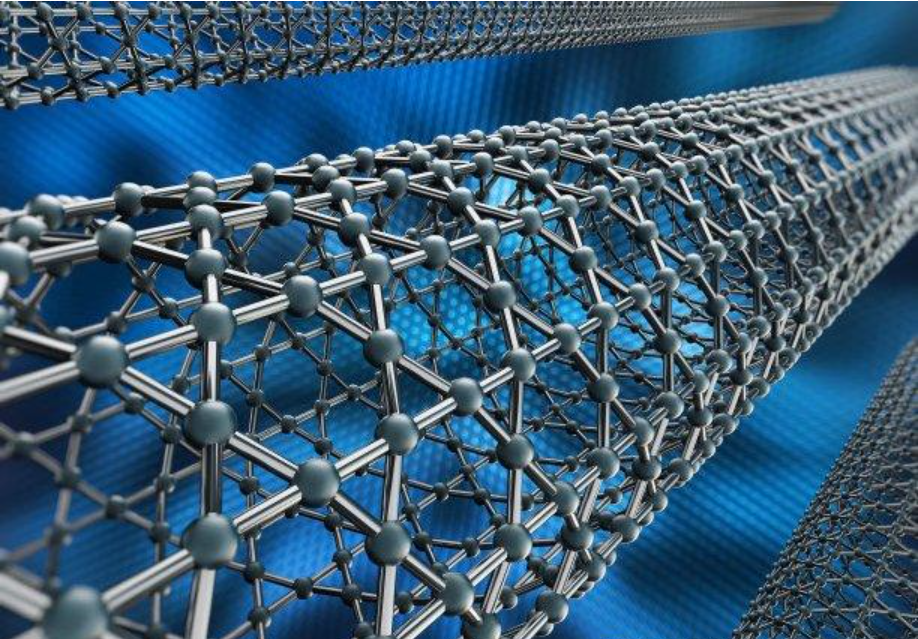

Hydrogen Storage Materials: Carbon Nanotubes for Fuel Cell Vehicles and Hydrogen Storage Systems

Hydrogen is a promising clean energy carrier, offering high energy density and zero carbon emissions when used in fuel cells. However, efficient hydrogen storage remains a critical challenge in realizing hydrogen’s potential as a sustainable energy source. Carbon nanotubes (CNTs) have emerged as one of the most promising materials for hydrogen storage due to their unique properties, including high surface area, excellent mechanical strength, and tunable adsorption capabilities.

This article delves into the use of CNTs as hydrogen storage materials, exploring their storage mechanisms, advantages, applications in fuel cell vehicles and hydrogen storage systems, market trends, and challenges.

Key Properties of Carbon Nanotubes for Hydrogen Storage

- High Surface Area

- CNTs provide a vast surface area for hydrogen adsorption, enhancing storage capacity. The specific surface area of CNTs can exceed 1000 m²/g, making them highly effective for gas storage.

- Hollow Structure

- The hollow structure of CNTs allows for the encapsulation of hydrogen molecules within their inner cavities, improving storage density.

- Lightweight Nature

- CNTs are lightweight materials, making them ideal for applications where weight is a critical factor, such as in fuel cell vehicles.

- High Mechanical Strength

- CNTs’ exceptional mechanical properties ensure structural stability under high-pressure storage conditions, a common requirement for hydrogen storage systems.

- Functionalizability

- CNTs can be chemically modified to enhance hydrogen adsorption through interactions such as physisorption and chemisorption.

Mechanisms of Hydrogen Storage in CNTs

1. Physisorption

In physisorption, hydrogen molecules are weakly bound to the surface of CNTs through van der Waals forces. This process occurs at low temperatures and is reversible, making it suitable for cyclic hydrogen storage applications.

- Key Feature: High surface area enhances the amount of hydrogen adsorbed.

2. Chemisorption

In chemisorption, hydrogen atoms form covalent bonds with the carbon atoms in CNTs. While this mechanism provides stronger bonding and higher storage capacity, it is less reversible than physisorption.

- Key Feature: Functionalization of CNTs can improve chemisorption efficiency.

3. Spillover Effect

The spillover effect involves the transfer of hydrogen atoms from a catalyst, such as platinum, to the CNT surface, enhancing storage capacity. This effect is particularly useful in multi-walled CNTs (MWCNTs), which have greater structural stability.

Applications of CNTs in Hydrogen Storage

1. Fuel Cell Vehicles (FCVs)

Hydrogen-powered fuel cell vehicles require lightweight and efficient storage systems to achieve high energy efficiency and extended driving ranges. CNTs, with their high hydrogen storage capacity and lightweight properties, are an excellent fit for such applications.

- Example: Research has demonstrated that CNTs can store up to 6.5 wt% of hydrogen under optimal conditions, meeting the U.S. Department of Energy’s (DOE) target for hydrogen storage materials in FCVs.

- Benefits:

- High energy density for extended driving ranges.

- Lightweight storage systems that reduce vehicle weight and improve fuel efficiency.

2. Stationary Hydrogen Storage Systems

CNTs are also used in stationary hydrogen storage systems for renewable energy applications. These systems store excess hydrogen produced from renewable sources like wind and solar energy, ensuring a stable energy supply during periods of low generation.

- Example: CNT-based storage tanks have been proposed for integrating with hydrogen refueling stations, providing high-pressure, compact storage solutions.

- Benefits:

- Compact design reduces space requirements.

- High-pressure resistance ensures safety and durability.

Advantages of CNTs for Hydrogen Storage

- Reversible Storage:

- Hydrogen can be adsorbed and desorbed repeatedly with minimal degradation, ensuring long-term usability.

- High Storage Capacity:

- CNTs demonstrate storage capacities that approach DOE targets under optimized conditions.

- Safety and Stability:

- The structural integrity of CNTs ensures safe hydrogen storage under high pressures and varying temperatures.

- Lightweight Design:

- Reduces the overall weight of storage systems, crucial for mobility applications like FCVs.

Real-World Examples and Research Progress

1. Improved Hydrogen Adsorption via Functionalization

Functionalized CNTs, such as those doped with boron or nitrogen, have shown enhanced hydrogen adsorption capabilities. For instance, nitrogen-doped CNTs can achieve up to 8 wt% hydrogen storage at cryogenic temperatures.

2. Composite Materials for Storage Systems

Combining CNTs with metal hydrides has resulted in composite materials with improved hydrogen storage performance. These composites leverage the high capacity of metal hydrides and the lightweight, high-surface-area properties of CNTs.

3. CNT-Based Tanks for Refueling Stations

CNTs have been tested in hydrogen storage tanks for use in hydrogen refueling stations. These tanks offer higher storage densities compared to conventional materials, enabling more efficient refueling operations.

Market Trends and Potential

The global hydrogen storage market is expected to grow significantly, driven by increasing investments in hydrogen infrastructure and the adoption of fuel cell technologies. CNT-based hydrogen storage materials are gaining attention due to their superior properties and compatibility with emerging hydrogen technologies.

Key Market Drivers:

- Rising demand for clean energy solutions in transportation and stationary applications.

- Government incentives and policies supporting hydrogen fuel adoption.

- Advancements in material science and nanotechnology for efficient hydrogen storage.

Market Applications:

- Automotive: Adoption in FCVs to achieve extended driving ranges.

- Renewable Energy: Integration with renewable hydrogen production systems for energy storage.

- Industrial: Use in hydrogen storage for industrial processes requiring high-purity hydrogen.

Challenges in CNT-Based Hydrogen Storage

- Cost of Production:

- The high cost of synthesizing high-quality CNTs limits their widespread adoption.

- Hydrogen Storage Conditions:

- CNTs often require low temperatures and high pressures to achieve optimal storage capacities, which can be expensive and energy-intensive.

- Scalability:

- Scaling up CNT production while maintaining quality and performance remains a challenge.

- Material Stability:

- Long-term stability of CNTs under cyclic storage conditions needs to be improved for commercial applications.

- Regulatory Barriers:

- Ensuring compliance with safety standards and gaining regulatory approval for CNT-based storage systems is a significant hurdle.

Future Directions

- Material Optimization:

- Ongoing research aims to enhance the hydrogen storage capacity of CNTs through chemical doping, functionalization, and hybrid materials.

- Cost Reduction:

- Advances in manufacturing techniques, such as chemical vapor deposition (CVD) and roll-to-roll processing, are expected to reduce the production costs of CNTs.

- Integration with Fuel Cells:

- CNT-based hydrogen storage systems will be integrated directly with fuel cells, offering seamless energy conversion and storage solutions.

- Collaboration Across Industries:

- Partnerships between automotive, energy, and material science industries will drive innovation and commercialization of CNT-based storage solutions.

Conclusion

Carbon nanotubes hold immense potential as hydrogen storage materials, offering high storage capacity, lightweight design, and exceptional structural stability. Their application in fuel cell vehicles, renewable energy systems, and industrial processes could revolutionize the hydrogen economy. However, challenges related to cost, scalability, and regulatory compliance must be addressed to realize their full potential.

As research and development efforts continue, CNT-based hydrogen storage systems are expected to play a pivotal role in achieving a sustainable and efficient hydrogen-powered future.