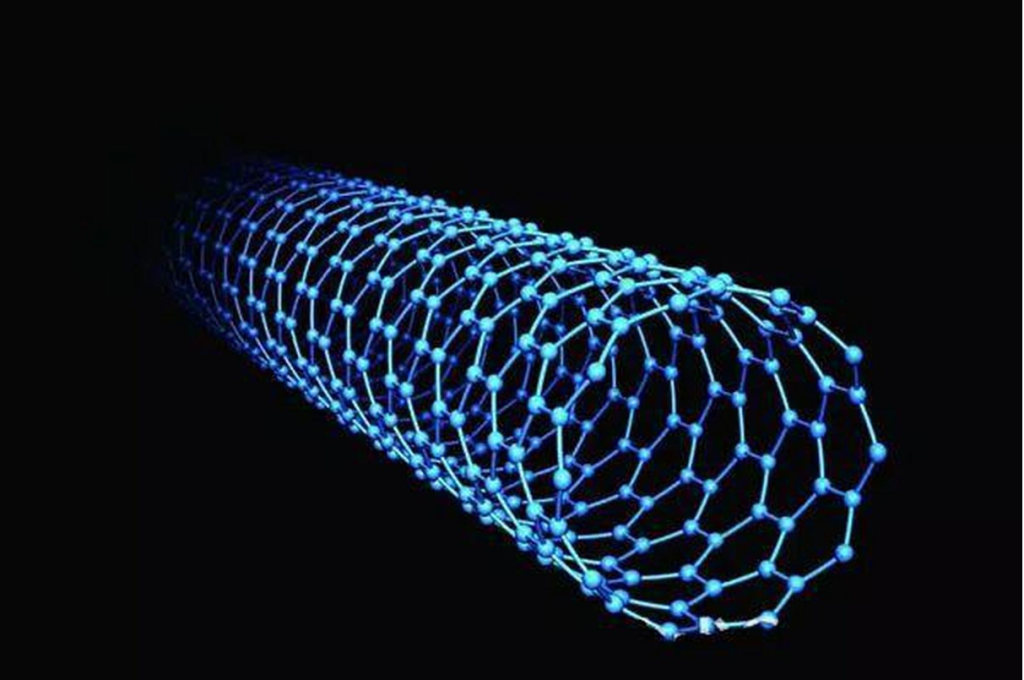

Is Carbon Nanotube a Game-Changer in Advanced Materials?

Carbon nanotubes (CNTs) have emerged as one of the most revolutionary materials in modern science. With exceptional electrical conductivity, mechanical strength, and thermal stability, they’re redefining what’s possible across multiple industries—from electronics and aerospace to energy storage and biomedicine.

In this article, we’ll take a closer look at what makes carbon nanotubes so unique, the key features that drive their performance, and how they compare to conventional materials. Whether you’re a researcher, engineer, or simply curious about future materials, understanding carbon nanotubes is crucial in staying ahead of the innovation curve.

What Makes Carbon Nanotubes Exceptional? Key Properties to Know

Carbon nanotubes stand out due to a rare combination of extraordinary properties, all packed into a nanoscale cylinder of carbon atoms. Unlike traditional materials, CNTs possess attributes that span multiple domains, offering transformative benefits in various applications.

Understanding what makes CNTs exceptional will help you evaluate their potential in your specific use case. Below, we break down the core properties that make them a true game-changer in the field of advanced materials.

Key Features to Look for in Carbon Nanotubes

-

Unmatched Strength-to-Weight Ratio

CNTs are among the strongest materials known, with tensile strength up to 100 times greater than steel, while being a fraction of the weight. This makes them ideal for high-performance composites in aerospace, automotive, and sports gear. -

Exceptional Electrical Conductivity

Due to their unique structure, CNTs can behave as either metals or semiconductors. Metallic CNTs can conduct electricity better than copper, making them ideal for next-gen wiring, EMI shielding, and nanoscale electronics. -

Superior Thermal Conductivity

CNTs have thermal conductivities as high as 3,000–6,000 W/m·K, outperforming even diamond. This makes them highly effective in heat dissipation applications like thermal interface materials and high-performance electronics. -

Nanoscale Dimensions and High Aspect Ratio

With diameters in the nanometer range and lengths that can span millimeters, CNTs are uniquely suited for reinforcing materials and building nanoscale structures or devices. -

Chemical Stability and Functionalizability

CNTs are chemically stable but can also be functionalized to interact with polymers, metals, and biological systems. This tunability allows integration across diverse sectors including medical diagnostics, water purification, and flexible electronics. -

Light Absorption and Field Emission Properties

Their ability to absorb light and emit electrons at low voltages opens doors for applications in sensors, photovoltaics, and field-emission displays.

Top Benefits of Using Carbon Nanotubes in Modern Applications

CNTs offer far-reaching benefits for both established industries and emerging technologies. Their multi-functional performance makes them a top choice for future-proofing your designs and innovations.

Enhanced Performance in Composites

Carbon nanotubes improve the mechanical, electrical, and thermal properties of polymer, metal, and ceramic composites, enabling stronger, lighter, and more durable materials.

Breakthroughs in Electronics

From transparent conductive films to flexible circuits, CNTs are enabling more compact, efficient, and flexible electronic devices.

Accelerated Energy Storage

In batteries and supercapacitors, CNTs increase electrode conductivity and surface area, resulting in faster charge times and higher energy density.

Next-Level Sensing and Medical Applications

Their sensitivity to chemical and biological molecules makes them perfect for biosensors, drug delivery systems, and cancer treatment innovations.

Are Carbon Nanotubes Better than Traditional Materials?

Carbon nanotubes outperform traditional materials in numerous critical aspects. While metals like copper and aluminum have long been used for conductivity, CNTs offer lighter, stronger, and more flexible alternatives with higher current-carrying capacities.

In structural applications, CNTs replace or reinforce materials like steel or carbon fiber composites, offering better performance at lower weight. Even in thermal management, CNTs rival or surpass materials like graphite or ceramics.

However, realizing their full potential often depends on overcoming challenges like dispersion in matrices, scale-up production, and consistent quality. When properly handled, CNTs can redefine what’s possible across technology and industry.

The Impact of Carbon Nanotubes on Global Industry

The influence of CNTs extends across key sectors:

-

Aerospace & Automotive: Used in ultra-lightweight, high-strength composites.

-

Electronics & Semiconductors: Building blocks for future flexible and miniaturized electronics.

-

Energy: Enhancing performance in lithium-ion batteries, supercapacitors, and even solar cells.

-

Healthcare: From biosensors to targeted therapies, CNTs are driving medical breakthroughs.

-

Textiles & Coatings: Imparting conductivity, antibacterial properties, and strength to fabrics and coatings.

Their impact is transformative, lowering weight and material costs, improving efficiency, and enabling sustainable designs in both high-tech and mass-market products.

How to Choose the Right Carbon Nanotube for Your Application?

Not all CNTs are created equal. The choice between single-walled (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) can greatly influence performance.

Step 1: Define Your Application

Are you aiming for conductivity, strength, or thermal performance? SWCNTs offer higher conductivity and flexibility, while MWCNTs are more cost-effective and mechanically robust.

Step 2: Evaluate Dispersion Needs

CNTs must be well-dispersed to function effectively in composites or liquids. Ask about surface treatments or functionalized CNTs for your specific matrix (e.g., polymers, resins).

Step 3: Consider Purity and Quality

Impurities can impact performance and safety. Check for high purity (typically 90%+) and low metal content for electronic or biomedical applications.

Step 4: Look for Supplier Reliability and Technical Support

Work with a supplier who can provide technical documentation, COA (certificate of analysis), and assist in formulation or processing.

Limitations and How to Overcome Them

Despite their strengths, CNTs face several practical challenges:

-

Dispersion Difficulties: CNTs tend to agglomerate due to van der Waals forces. This can be solved through surfactants, functionalization, or ultrasonic dispersion.

-

Cost: High-purity SWCNTs are still relatively expensive. Choosing MWCNTs or blended materials may offer cost-effective alternatives for less critical applications.

-

Toxicity Concerns: Certain forms of CNTs may pose health risks if inhaled. Ensure safe handling protocols and consider using embedded or coated forms for safer usage.

If you’re ready to dive deeper into using carbon nanotubes for your project or product, feel free to ask for recommendations on CNT types, applications, or sourcing support. Let’s bring your advanced material innovation to life!