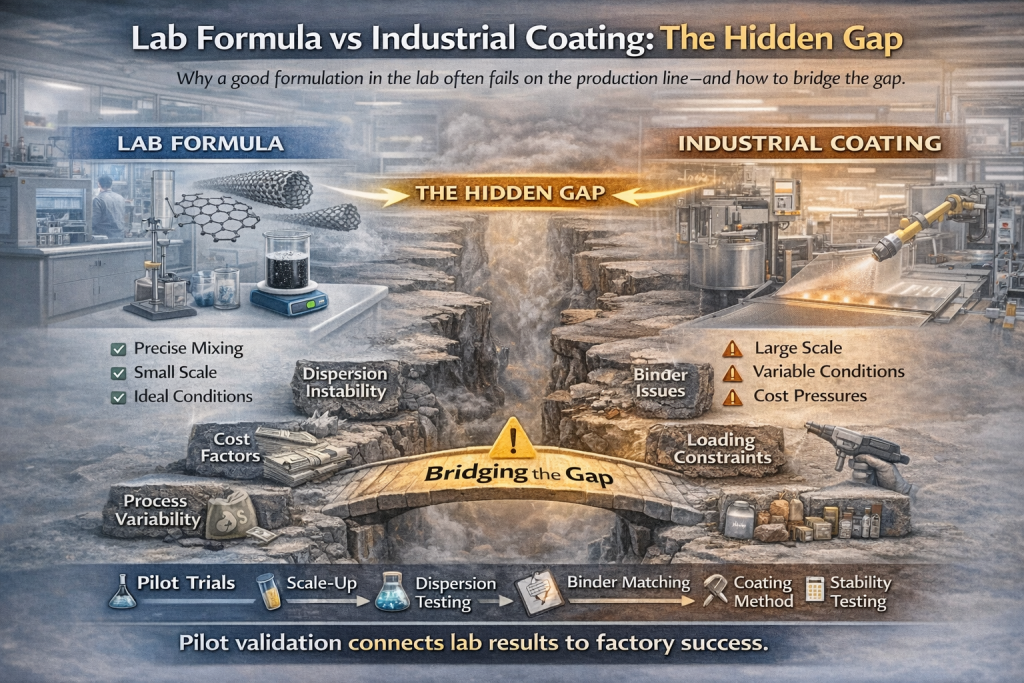

Lab Formula vs Industrial Coating: The Hidden Gap

Understanding the differences between idealized lab formulations and real-world coating challenges.

1. The allure of lab results

In a controlled lab environment, coatings with remarkable properties are easy to achieve:

-

Perfect dispersion

-

Uniform thickness

-

Controlled drying and curing conditions

-

Precise chemical interactions

It’s a world of controlled variables where the coating system performs at its best, often exceeding expectations for things like:

-

Corrosion resistance

-

Wear resistance

-

Adhesion strength

-

Thermal stability

However, when it comes to scaling up for industrial use, the transition from lab to real-world applications introduces a complex set of challenges.

2. Why lab results don’t always translate

1. Dispersion stability

In the lab, dispersion of solid particles like graphene or CNTs is carefully controlled. But scaling up often leads to:

-

Agglomeration of particles

-

Difficulty maintaining uniform distribution

-

Reduced performance in large-scale applications

2. Coating thickness control

Lab formulations often apply coatings in thin, consistent layers. In industrial settings, achieving even coating thickness at high speeds or on uneven substrates becomes much more challenging, leading to:

-

Inconsistent protection

-

Poor corrosion resistance

-

Flaking or peeling issues

3. Environmental factors

Lab conditions are ideally controlled — temperature, humidity, and cleanliness. Industrial environments, on the other hand, often deal with:

-

Variability in temperature and humidity

-

Dust or particulate contamination

-

Handling during production or transport

These factors can degrade the performance of coatings that worked well in the lab.

4. Curing and drying

In the lab, curing methods can be optimized for a specific formulation. In industry, curing times, temperatures, and even the type of curing process may vary. This affects:

-

Hardness and adhesion

-

Chemical resistance

-

Overall durability

5. Material interactions

In the lab, individual components like resins, solvents, and additives are tested in isolation. In real-world applications, however, these materials must interact with each other, with the substrate, and with environmental factors — often leading to unexpected results.

3. Real-world industrial challenges

1. Process variability

Industrial processes like spraying, dipping, and electrostatic coating introduce significant variability. Factors like:

-

Spray pressure

-

Coating speed

-

Humidity and substrate temperature

…can lead to variations in how the coating performs, even when the lab formulation should work theoretically.

2. Cost and scalability

Lab formulations often use high-purity materials, precision equipment, and controlled conditions. Scaling these formulations for mass production introduces challenges:

-

Increased raw material costs

-

Difficulty sourcing high-purity or rare materials

-

Scaling up production processes without compromising quality

3. Durability under stress

Lab tests typically use idealized conditions (e.g., uniform stress, controlled environment). In real applications, coatings may face:

-

Mechanical abrasion

-

Thermal cycling

-

Chemical exposure from contaminants or aggressive fluids

Coatings need to be tested for long-term wear, impact resistance, and environmental exposure.

4. Closing the gap: Strategies for success

1. Pilot-scale validation

Testing formulations on a pilot scale helps identify issues like dispersion stability, coating thickness, and process consistency before scaling up to full industrial production.

2. Process optimization

Industry-specific processes (spraying, rolling, dipping) should be incorporated into the formulation design. This allows coatings to be optimized for real-world application methods.

3. Material hybridization

Lab formulations may focus on single-component systems, but real-world coatings often perform better when hybrid materials are used. Combining graphene with CNTs, polymers, or other fillers can enhance performance across multiple dimensions — mechanical, thermal, and chemical.

4. Long-term field testing

No matter how promising a lab formula seems, real-world exposure is crucial. Field testing under actual operating conditions ensures that coatings hold up under the stress they will face in use.

5. Focus on practical performance

Lab results are often based on ideal metrics (e.g., perfect adhesion or resistance), but real-world coatings need to perform across a range of variables. Focus on performance metrics that reflect true operating conditions, such as:

-

Resistance to wear under load

-

Performance at varying temperatures

-

Resistance to environmental chemicals and UV exposure

5. Key takeaways

-

Lab formulas are often idealized, focusing on perfect conditions that do not exist in industrial environments.

-

Real-world industrial coatings must contend with variability in temperature, process, contamination, and mechanical stress.

-

Pilot validation and field testing are crucial to bridging the gap between lab results and industrial success.

-

The cost of lab-scale materials and precision processes must be balanced with scalability and material sourcing for industrial production.

-

Hybrid systems (combining materials and modifying formulations) are often necessary for improving industrial coating performance.

To create effective industrial coatings, engineers must move beyond ideal lab conditions and design formulations that can handle real-world variability. Effective pilot testing, process optimization, and durability testing are key to bridging this gap.