Laser-Induced Graphene in Wearable Flexible Sensors for the Human Body

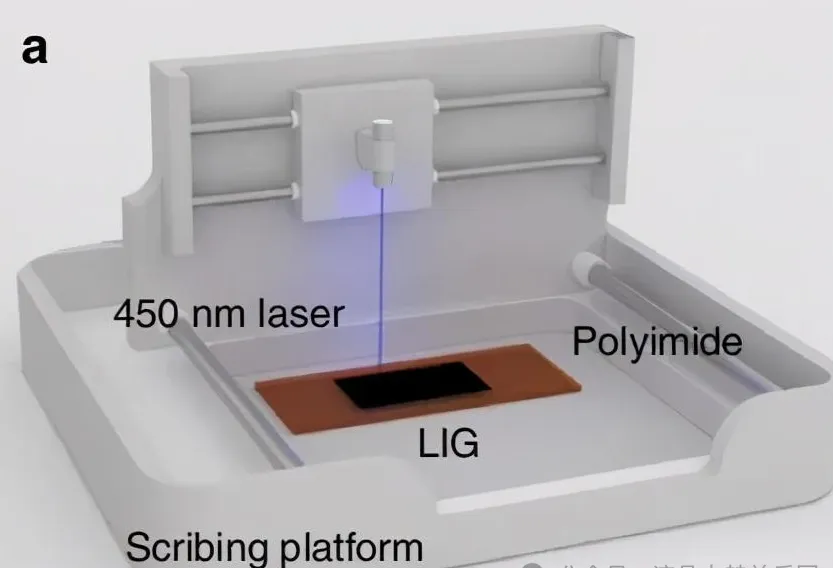

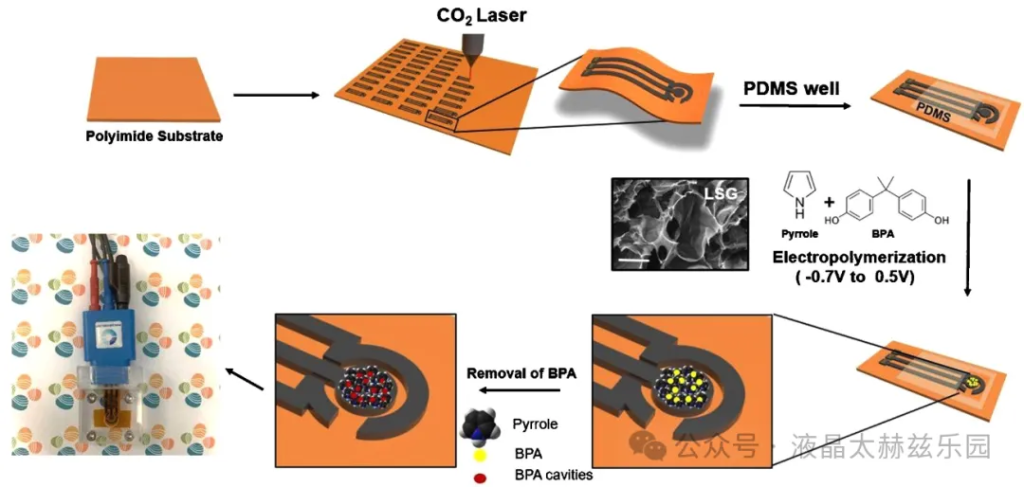

Laser-Induced Graphene (LIG) is a graphene material produced through a process called laser-induced pyrolysis, where a laser is used to convert carbon-containing polymers into graphene. This technique, first introduced by researchers at Rice University in 2014, uses the high energy density of lasers to carbonize the surface of polymers, forming a porous graphene structure. The process of creating LIG is straightforward, quick, and does not require complex chemical treatments, making it cost-effective, environmentally friendly, and scalable.

LIG’s application in sensor technology leverages its unique physical and chemical properties. First, its high surface area provides numerous active sites, enhancing interaction with target analytes. Second, LIG’s excellent conductivity allows it to function as an electrode material, quickly responding to changes in electrochemical signals. Additionally, the porous structure and chemical stability of LIG enable it to adapt to various environmental conditions, with the ability to fine-tune its sensing properties through laser parameter adjustments.

LIG shows significant potential in the development of wearable flexible sensors for the human body. Its simple and rapid production process, free from complicated chemical steps, makes it an ideal material for manufacturing flexible electronic devices.

In wearable flexible sensors, LIG’s unique properties play a crucial role:

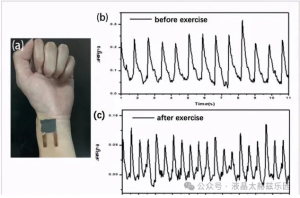

- Physiological Signal Monitoring: LIG can be used to create sensors for heart rate, respiration, and muscle activity monitoring. Its flexibility and conductivity allow it to conform closely to the skin, providing real-time physiological data for health management and disease diagnosis.

- Motion Tracking: LIG-based sensors can monitor body movements and posture, useful in sports training, rehabilitation, and elderly care.

- Environmental Monitoring: LIG can be employed in environmental sensors to monitor parameters like temperature, humidity, and harmful gas concentrations, important for personal health protection and indoor environment control.

Advantages of LIG in Wearable Flexible Sensors:

- Flexibility: LIG can be produced on flexible substrates, making sensor design and manufacturing more versatile and integrative, suitable for various body movements and postures.

- Comfort: The lightweight and soft properties of LIG materials ensure comfort during wear, without disrupting daily activities.

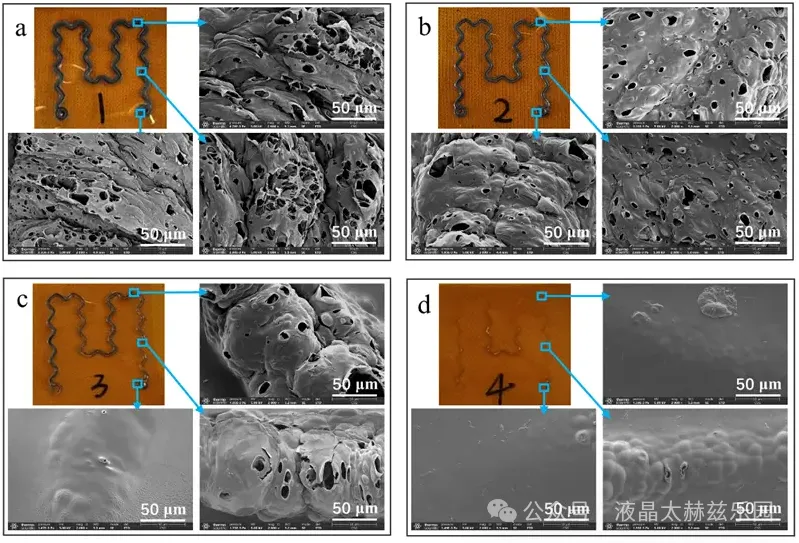

- Performance Tunability: By adjusting laser parameters, the structure and performance of LIG can be precisely controlled, optimizing sensor response characteristics and sensitivity.

- Versatility: LIG’s porous structure and chemical stability make it adaptable for various sensing applications, with the potential for enhanced selectivity and sensitivity through surface modification.

The application of laser-induced graphene in wearable flexible sensors holds great promise for the future. As technology advances and research deepens, LIG is expected to play a significant role in the wearable device market.

Source: Graphene Alliance