Multi-Walled vs Single-Walled Carbon Nanotubes: Performance Comparison and Selection Optimization for Different Applications

Introduction

Carbon nanotubes (CNTs), both multi-walled (MWCNTs) and single-walled (SWCNTs), are widely recognized for their extraordinary mechanical, electrical, and thermal properties. These properties make CNTs ideal for various applications, ranging from structural composites to energy storage devices and biomedical applications. While both MWCNTs and SWCNTs share many advantages, they also exhibit significant differences in performance, which make them better suited for different applications. In this article, we will explore the comparative performance of MWCNTs and SWCNTs and discuss how to optimize their selection for specific use cases.

Structural Differences between MWCNTs and SWCNTs

Before delving into the performance comparison, it’s important to understand the structural differences between multi-walled and single-walled carbon nanotubes:

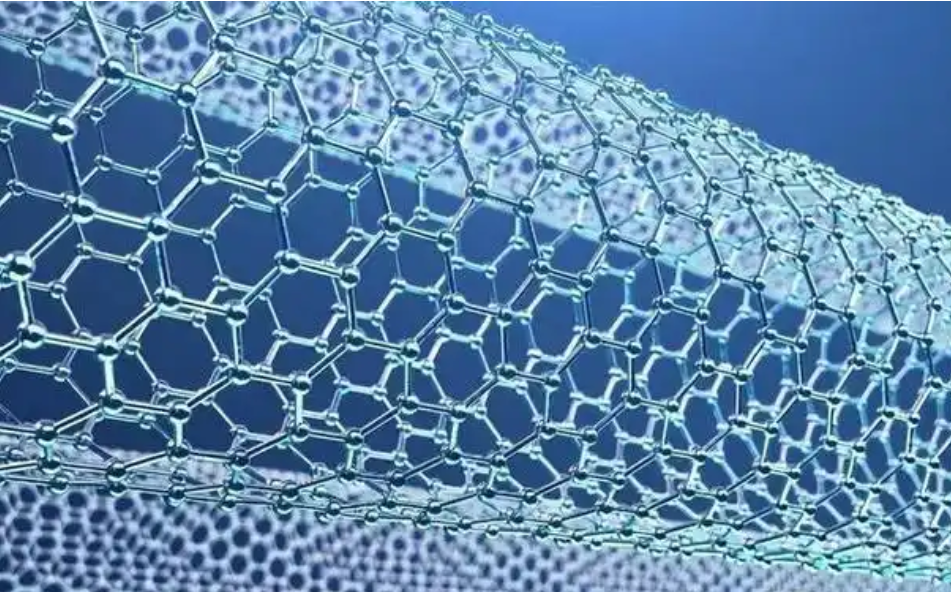

- Single-Walled Carbon Nanotubes (SWCNTs): These CNTs consist of a single cylindrical graphene sheet rolled into a tube. They have a diameter typically in the range of 0.6-2 nm and a length that can reach several micrometers. SWCNTs have a higher aspect ratio and are more flexible than MWCNTs.

- Multi-Walled Carbon Nanotubes (MWCNTs): MWCNTs consist of multiple concentric graphene cylinders, with an inner tube surrounded by one or more outer layers. The diameter of MWCNTs can range from 2 nm to several hundred nanometers. MWCNTs are typically stiffer and stronger than SWCNTs due to the additional graphene layers.

Performance Comparison

The performance characteristics of MWCNTs and SWCNTs vary significantly based on their structure, which affects their performance in different application scenarios. Let’s break down the performance aspects for comparison.

1. Mechanical Properties

- Strength: MWCNTs typically exhibit superior mechanical strength due to their multi-layered structure, with the added graphene layers providing increased reinforcement. This makes MWCNTs particularly beneficial for reinforcing composite materials in structural applications.

- Flexibility: SWCNTs are more flexible due to their single-layer structure, making them ideal for applications requiring high flexibility, such as flexible electronics and wearable technologies.

- Tensile Strength: SWCNTs generally possess a higher tensile strength on a per-tube basis, due to their simpler and more perfect structure. However, MWCNTs exhibit greater overall strength in composite materials due to their multiple walls.

2. Electrical Conductivity

- Conductivity in Electrical Systems: SWCNTs are known for their excellent electrical conductivity, which is comparable to that of copper. They are particularly effective as conductive materials in applications such as transistors, sensors, and conductive inks.

- Conductivity in Composite Materials: MWCNTs, although slightly less conductive than SWCNTs, still offer excellent electrical conductivity, particularly when used in composite materials. Their multiple layers provide more opportunities for conducting pathways in the material, making them suitable for applications like electromagnetic interference (EMI) shielding and conductive coatings.

3. Thermal Properties

- Thermal Conductivity: Both MWCNTs and SWCNTs exhibit high thermal conductivity, but SWCNTs generally have higher thermal conductivity due to their more uniform structure and smaller diameter. This makes SWCNTs ideal for applications where heat dissipation is critical, such as in heat sinks or high-performance electronic components.

- Thermal Stability: MWCNTs tend to exhibit better thermal stability due to their multiple layers, which offer greater resistance to thermal degradation, especially in high-temperature environments.

4. Surface Area and Adsorption Capacity

- Surface Area: SWCNTs generally have a higher specific surface area due to their smaller diameter, which makes them more suitable for applications in sensors, energy storage, and catalysis, where surface interactions are crucial.

- Surface Modification: MWCNTs, due to their larger diameter and more complex structure, may require more extensive surface modification to achieve optimal dispersion and compatibility with various matrices in composite materials.

Applications and Selection Optimization

The choice between MWCNTs and SWCNTs depends largely on the specific needs of the application. Below are several key application areas and recommendations for CNT selection:

1. Composite Materials

- MWCNTs: For reinforcing materials such as polymers, metals, or ceramics, MWCNTs are the better choice due to their superior strength and durability. MWCNTs are commonly used in aerospace, automotive, and construction industries to create lightweight, high-strength composites.

- SWCNTs: If the goal is to achieve superior mechanical properties on a per-tube basis, SWCNTs may be preferred, but they are typically used in more specialized, high-performance composites, such as those used in the electronics and aerospace industries.

2. Energy Storage and Supercapacitors

- SWCNTs: Due to their high surface area and excellent electrical conductivity, SWCNTs are favored for energy storage applications like supercapacitors and batteries. They provide efficient electron transport and enhanced charge/discharge rates.

- MWCNTs: MWCNTs are often used in hybrid supercapacitors and batteries, where their mechanical properties and conductivity help enhance the performance of the device.

3. Electronics and Sensors

- SWCNTs: The high electrical conductivity and flexibility of SWCNTs make them ideal for use in sensors, transistors, and flexible electronics. SWCNTs are also highly effective in creating conductive inks for printed electronics.

- MWCNTs: MWCNTs are used in applications requiring EMI shielding, conductive coatings, and other applications where high mechanical strength and moderate conductivity are needed.

4. Biomedical Applications

- SWCNTs: SWCNTs are preferred in biomedical applications due to their superior ability to interact with biological molecules, making them ideal for drug delivery systems, cancer therapy, and bioimaging.

- MWCNTs: MWCNTs may be used in medical implants or scaffolds for tissue engineering, where mechanical strength and durability are crucial.

Conclusion

Both multi-walled and single-walled carbon nanotubes have distinct advantages that make them suited for different applications. While MWCNTs excel in strength, thermal stability, and composite materials, SWCNTs outperform in flexibility, electrical conductivity, and energy storage. The selection of the appropriate type of CNT should be based on specific performance needs, such as strength, conductivity, or surface area. By understanding the unique properties of each, industries can optimize their use of CNTs for a wide range of innovative applications.

Keywords

Multi-Walled Carbon Nanotubes, Single-Walled Carbon Nanotubes, CNT Performance Comparison, Carbon Nanotube Applications, Electrical Conductivity, Thermal Conductivity, Composite Materials, Energy Storage, Biomedical Applications, Surface Area, Selection Optimization.