Optimizing Lithium-Ion Battery Performance in Low-Temperature Environments: The Role of Carbon Materials in Enhancing Discharge Capability

Lithium-ion batteries (LIBs) are the cornerstone of modern energy storage systems, powering electric vehicles (EVs), portable electronics, and renewable energy grids. However, their performance significantly declines in low-temperature environments, a critical challenge for regions with harsh winters or applications such as aerospace and high-altitude operations. At low temperatures, LIBs exhibit reduced capacity, lower energy efficiency, and slower charge-discharge rates.

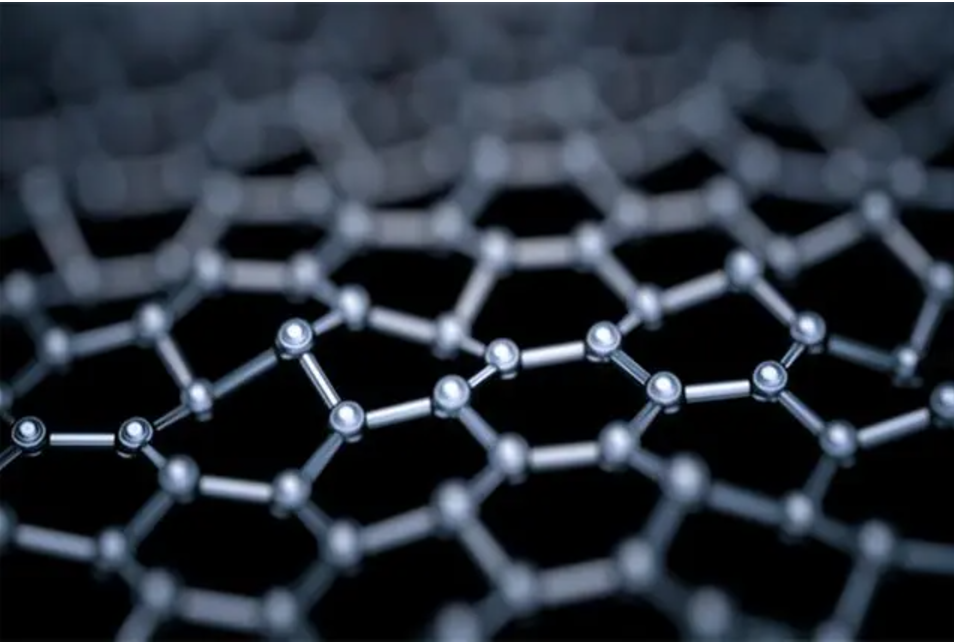

Carbon materials—such as graphite, graphene, carbon nanotubes (CNTs), and carbon composites—are emerging as key players in improving low-temperature performance. This article explores the mechanisms behind LIB degradation in cold conditions, the properties of carbon materials that address these challenges, and their practical applications in enhancing low-temperature discharge capability.

1. Challenges of Lithium-Ion Batteries in Low-Temperature Conditions

1.1 Decline in Capacity

At sub-zero temperatures, the electrolyte’s viscosity increases, slowing lithium-ion mobility. This reduces the available capacity and limits power output.

1.2 Poor Kinetics

Low temperatures hinder the charge-transfer process at the electrode-electrolyte interface, resulting in higher internal resistance and slower electrochemical reactions.

1.3 Lithium Plating

During charging, especially at low temperatures, lithium metal tends to deposit on the anode surface instead of intercalating into it. This leads to permanent capacity loss and safety risks such as dendrite formation.

1.4 Mechanical Strain

Repeated cycling in cold environments exacerbates electrode expansion and contraction, causing structural damage and increasing the risk of electrode delamination.

2. The Role of Carbon Materials in Enhancing Low-Temperature Performance

Carbon materials are ideal for addressing the limitations of LIBs in low-temperature environments due to their exceptional conductivity, structural stability, and surface properties.

2.1 Graphite

Advantages

- Thermal Stability: Graphite maintains its structural integrity across a wide temperature range, preventing mechanical damage during cycling.

- Fast Ion Transport: Its layered structure allows lithium ions to diffuse efficiently, even at low temperatures.

Example

In a study conducted by Panasonic, high-quality natural graphite anodes demonstrated a 10% higher capacity retention at -20°C compared to standard synthetic graphite.

Challenges

Graphite suffers from slow lithium intercalation at extremely low temperatures, necessitating modifications such as coatings or doping.

2.2 Graphene

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers superior conductivity and surface properties that enhance low-temperature LIB performance.

Advantages

- High Electron Mobility: Graphene’s extraordinary conductivity facilitates faster electron transfer, compensating for kinetic losses in cold conditions.

- Reduced Impedance: Its large surface area improves contact with the electrolyte, lowering overall impedance and enhancing charge transfer.

- Thermal Conductivity: Graphene dissipates heat efficiently, preventing localized freezing of the electrolyte.

Example

Research by the University of Manchester showed that graphene-coated anodes retained 85% of their room-temperature capacity at -30°C, outperforming conventional graphite anodes.

Challenges

High production costs and the complexity of integrating graphene into commercial LIBs remain barriers.

2.3 Carbon Nanotubes (CNTs)

CNTs are hollow cylindrical structures with exceptional electrical and mechanical properties, making them ideal additives for LIB electrodes.

Advantages

- Network Formation: CNTs create conductive networks within electrodes, ensuring consistent electron flow even in cold environments.

- Electrolyte Interaction: Functionalized CNTs improve electrolyte wetting, enhancing ion transport at low temperatures.

- Mechanical Reinforcement: CNTs prevent electrode cracking and delamination during thermal cycling.

Example

A Chinese manufacturer integrated 1% CNTs into LIB anodes, achieving a 20% increase in capacity retention at -20°C compared to standard anodes.

Challenges

Dispersion challenges and compatibility with other materials require advanced processing techniques.

2.4 Hybrid Carbon Materials

Combining multiple carbon materials leverages their individual strengths to optimize LIB performance.

Example

Graphene-CNT hybrids have shown exceptional low-temperature performance by combining graphene’s high conductivity with CNTs’ structural reinforcement. In a study by MIT, such composites retained 90% of their initial capacity at -30°C.

3. Strategies for Low-Temperature Optimization Using Carbon Materials

3.1 Surface Modifications

Coatings and Doping

Surface modifications such as graphene coatings or nitrogen-doped carbon layers enhance the interaction between the electrode and electrolyte. These modifications:

- Lower activation energy for lithium-ion intercalation.

- Reduce side reactions that increase resistance.

Example:

A South Korean research group developed nitrogen-doped graphene anodes, achieving a 15% improvement in discharge rates at -20°C.

3.2 Thermal Management with Carbon Materials

Graphene Thermal Layers

Graphene’s exceptional thermal conductivity prevents cold spots and ensures uniform temperature distribution within the battery.

Example:

EV batteries with graphene-enhanced thermal management systems achieved consistent discharge rates in temperatures as low as -25°C.

3.3 Electrolyte Compatibility

Carbon materials can be functionalized to enhance compatibility with low-temperature electrolytes, reducing viscosity and improving ion transport.

Example:

Functionalized CNTs were used in LIBs for Arctic exploration, maintaining over 80% capacity at -40°C.

3.4 Structural Design Innovations

Porous Carbon Structures

Porous carbons with tailored pore sizes enhance electrolyte infiltration and ion diffusion at low temperatures.

Example:

A U.S. startup developed mesoporous carbon anodes with a 25% improvement in discharge rates at -30°C.

4. Applications and Case Studies

4.1 Electric Vehicles

- Tesla has explored graphene-enhanced anodes for maintaining performance in sub-zero climates, enabling EVs to operate efficiently in winter conditions.

4.2 Aerospace

- NASA has investigated CNT-reinforced electrodes for satellites and rovers, ensuring reliable power in extreme cold environments like Mars.

4.3 Renewable Energy Storage

- Hybrid carbon materials are being used in LIBs for wind and solar energy storage in cold regions, ensuring consistent output even during harsh winters.

5. Future Outlook

5.1 Scalable Production

Advancements in carbon material synthesis, such as chemical vapor deposition (CVD) and sustainable production methods, are reducing costs and enabling large-scale applications.

5.2 Integration with Solid-State Batteries

Carbon materials will play a crucial role in next-generation solid-state LIBs, addressing low-temperature challenges while improving safety and energy density.

5.3 Sustainability

Recycling carbon materials from end-of-life LIBs can create high-performance electrodes, contributing to a circular economy.

Conclusion

Low-temperature environments pose significant challenges for lithium-ion batteries, but high-performance carbon materials offer promising solutions. Graphite, graphene, carbon nanotubes, and hybrid materials enhance conductivity, structural stability, and thermal management, improving discharge capabilities and extending battery life. As advancements in material science and manufacturing continue, carbon materials will play a pivotal role in ensuring LIBs perform reliably in even the harshest conditions, driving progress in energy storage for EVs, aerospace, and renewable energy systems.