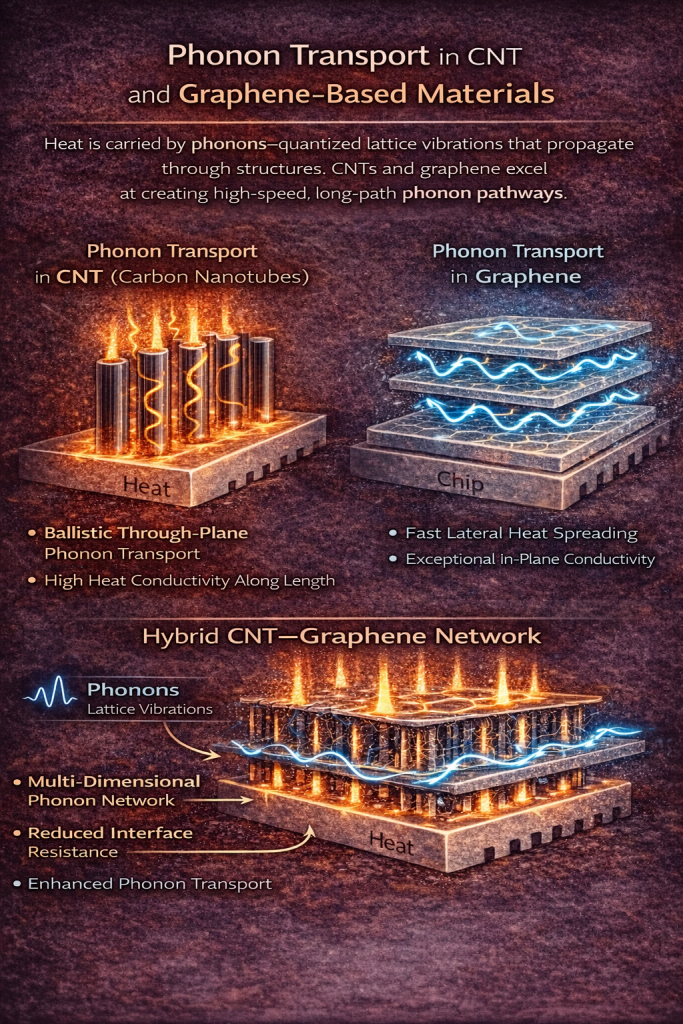

Phonon Transport in CNT and Graphene-Based Materials

Heat Moves as Phonons, Not Numbers

Thermal conductivity values are often treated as static numbers on a datasheet.

In reality, heat in CNT- and graphene-based materials is transported primarily by phonons—quantized lattice vibrations whose behavior is highly sensitive to structure, interfaces, and defects.

Understanding phonon transport explains why CNTs and graphene outperform conventional fillers, and why their performance depends so strongly on dispersion, alignment, and interfaces.

1. What Are Phonons and Why Do They Matter?

In non-metallic solids, heat is carried mainly by phonons rather than free electrons.

Phonon heat transport depends on:

-

Phonon velocity

-

Mean free path

-

Scattering mechanisms

The thermal conductivity k can be simplified as:

k∼C⋅v⋅lk \sim C \cdot v \cdot l

Where:

-

C = heat capacity

-

v = phonon velocity

-

l = phonon mean free path

CNTs and graphene excel because they allow fast phonon propagation with long mean free paths.

2. Phonon Transport in Carbon Nanotubes (CNTs)

One-Dimensional Heat Highways

CNTs behave as quasi-one-dimensional systems:

-

Phonons are confined along the tube axis

-

Very limited transverse scattering

-

Extremely high axial thermal conductivity (>3000 W/m·K in ideal cases)

Key characteristics

-

Ballistic or quasi-ballistic phonon transport over micron-scale lengths

-

Strong anisotropy (axial ≫ radial conductivity)

-

Sensitive to defects, bending, and tube–tube junctions

Engineering implication:

CNTs are exceptionally effective at through-plane heat bridging across interfaces and micro-gaps.

3. Phonon Transport in Graphene

Two-Dimensional Phonon Highways

Graphene is a 2D crystal with:

-

Strong sp² carbon bonding

-

High phonon group velocity

-

Long in-plane phonon mean free paths

This results in:

-

Exceptional in-plane thermal conductivity (2000–5000 W/m·K)

-

Efficient lateral heat spreading

Key limitation

-

Weak out-of-plane phonon coupling

-

Reduced effectiveness for through-plane transport unless assisted by CNTs or pressure

Engineering implication:

Graphene excels at heat spreading, not vertical heat transfer.

4. Phonon Scattering: Why Real Materials Perform Lower Than Theory

In practical CNT and graphene systems, phonons are scattered by:

-

Defects and vacancies

-

Grain boundaries

-

CNT–CNT junctions

-

CNT–graphene interfaces

-

Matrix–filler interfaces

Each scattering event shortens the phonon mean free path, reducing effective conductivity.

This explains why:

-

Poor dispersion drastically reduces performance

-

Excessive filler loading does not always improve heat transfer

5. Interfaces as Phonon Barriers

At interfaces, phonons experience:

-

Acoustic mismatch

-

Diffuse scattering

-

Reflection instead of transmission

This creates interfacial thermal resistance (Kapitza resistance).

In composites and TIMs:

-

Filler–filler interfaces

-

Filler–polymer interfaces

often dominate total thermal resistance.

6. Why Hybrid CNT–Graphene Networks Improve Phonon Transport

Hybrid systems mitigate phonon losses by:

-

CNTs providing vertical phonon pathways

-

Graphene offering lateral phonon highways

-

Reduced reliance on particle–particle contact

The CNT–graphene junction forms a multi-dimensional phonon network, reducing bottlenecks present in single-filler systems.

Result:

-

More continuous phonon transport

-

Lower interfacial thermal resistance

-

Higher effective conductivity at lower loading

7. Phonon Transport in CNT–Graphene TIMs and Coatings

In TIMs and coatings:

-

Thin bond lines limit bulk conduction

-

Interfaces dominate phonon loss

CNT–graphene systems improve performance by:

-

Maintaining phonon pathways under compression

-

Preserving contact during thermal cycling

-

Reducing void-induced phonon scattering

This is why they outperform traditional fillers even when bulk conductivity values appear similar.

8. Design Factors That Influence Phonon Transport

To maximize phonon transport:

-

Minimize structural defects

-

Control CNT length and alignment

-

Preserve graphene sheet integrity

-

Optimize filler–matrix coupling

-

Reduce unnecessary filler junctions

Key insight:

Phonon transport is a structural problem, not just a material selection problem.

Phonon Engineering Defines Thermal Performance

The exceptional thermal performance of CNT and graphene materials originates from how phonons move through their structures.

In real-world applications:

-

Defects, interfaces, and dispersion dominate behavior

-

Hybrid CNT–graphene networks offer superior phonon continuity

-

Effective thermal design requires phonon-aware material engineering

Understanding phonon transport allows engineers to move beyond datasheet values and design thermal systems that perform reliably in real assemblies.