Organic Solar Cells (Organic Photovoltaics, OPV): A Breakthrough in Solar Energy Conversion

Organic Solar Cells, or Organic Photovoltaics (OPV), refer to a class of solar cells that use organic semiconductor materials as the main component for converting light into electricity. As introduced in the materials section, organic semiconductors can be categorized into two types: small molecules and polymers. Small molecule materials are typically deposited through vacuum evaporation, while polymer materials can be processed using printing or solution-based methods, such as coating techniques.

German OPV manufacturer Heliatek uses the vacuum evaporation technique. By utilizing two patented light-absorbing materials, they are able to convert light across different wavelengths into electrical energy, achieving a record-breaking power conversion efficiency of 13.2% for OPV. Their product, HeliaSol, an “instant-use” solar film, boasts a conversion efficiency of 7% to 8%. Even their semi-transparent photovoltaic films, with 30% light transmittance, can still achieve a conversion efficiency of 6%.

OPV Based on Polymer Semiconductor Materials: Challenges and Progress in Production

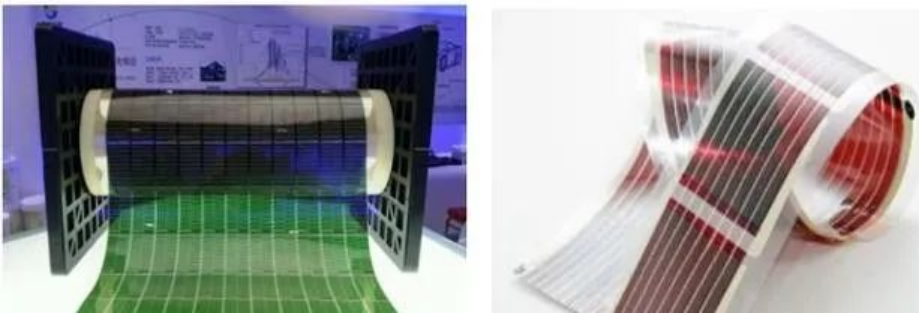

In OPV (Organic Photovoltaics) made with polymer semiconductor materials, all functional layers can be produced at low temperatures using solution-based methods. This makes them suitable for deposition on various flexible and heat-sensitive substrates, such as plastic films, paper, and even fabrics. In laboratory settings, the most efficient OPVs are typically produced using spin-coating—a technique not ideal for industrial-scale photovoltaic production.

In practical production, the effective electron transport distance in organic semiconductor materials is only about 100nm, making it difficult to create functional layers thicker than 200nm. While OPV can theoretically be produced through printing methods, the thinness of the films and the inability to add fillers pose significant challenges to printing technology in actual production.

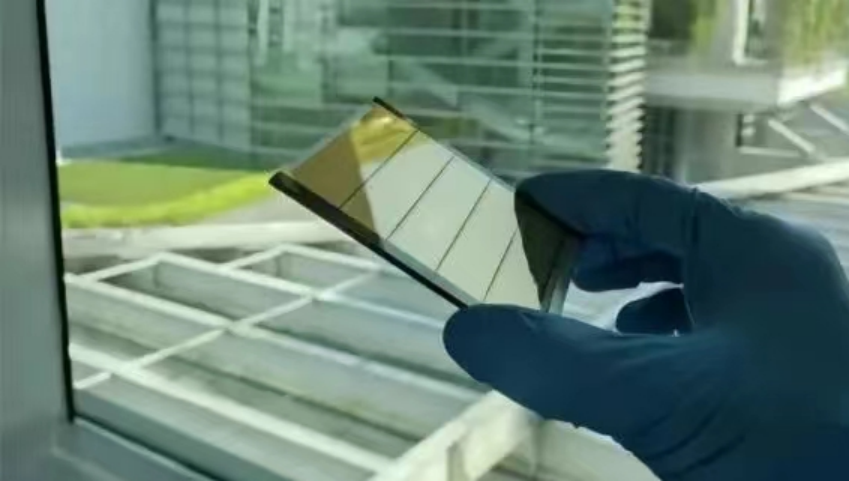

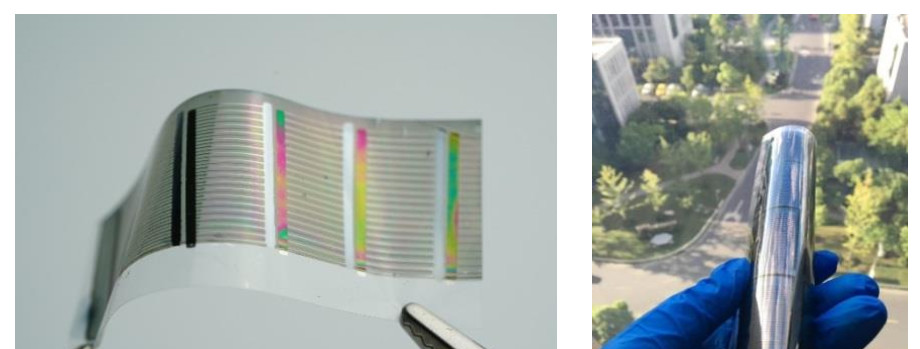

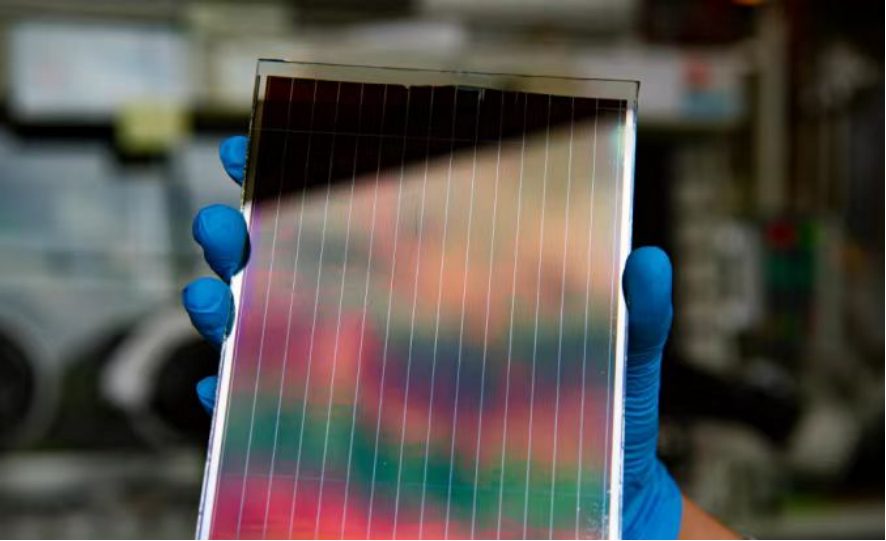

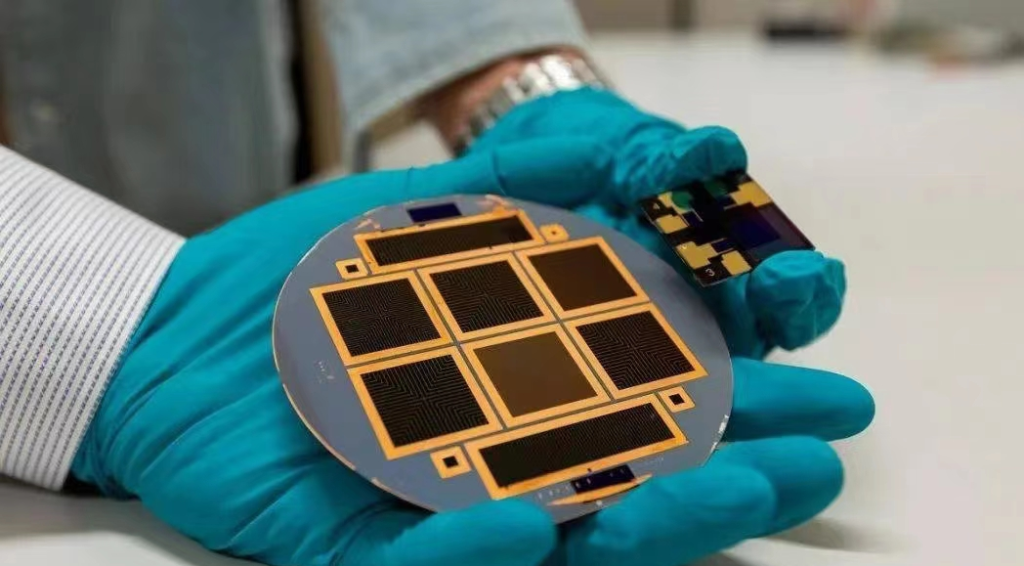

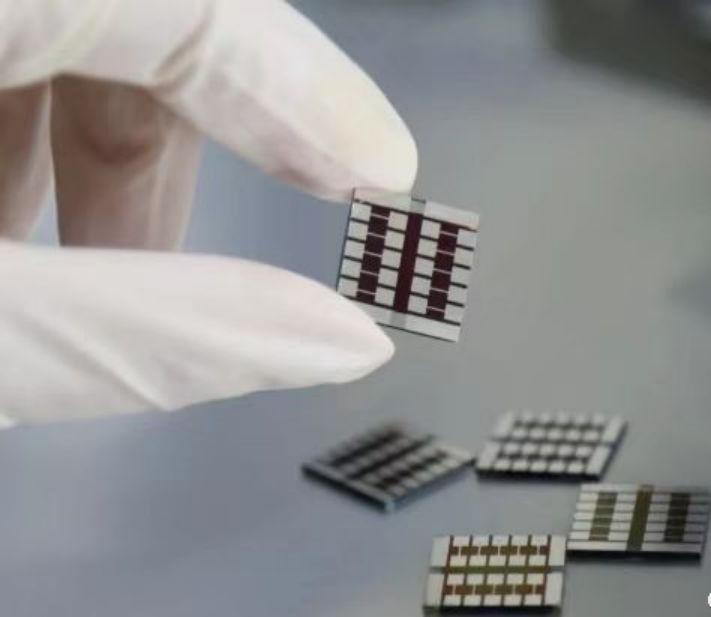

Pioneering OPV companies like Konarka and Solarmer, and research institutions such as the Frederik C. Krebs Group in Denmark and the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia, have made significant progress using slot-die coating technology for OPV fabrication. These efforts demonstrate the potential of slot-die coating for large-scale OPV production. Figure 87 showcases photos of OPV products produced by various organizations using this technology.

Figure: OPV Products Manufactured Using Slot-Die Coating Technology

Thanks to the unlimited design possibilities of polymer molecules, developing new photovoltaic materials has long been a popular topic in the scientific community. Over the past decade, the European Union has implemented a series of research projects related to Organic Photovoltaics (OPV). Similarly, several research teams in China have been actively working in the OPV field, with support from the National Natural Science Foundation of China and the Ministry of Science and Technology.

In terms of developing OPV printing technologies, China’s progress has kept pace with international developments. Renowned research institutions such as Peking University, the National Center for Nanoscience and Technology, the Institute of Chemistry at the Chinese Academy of Sciences, the Suzhou Institute of Nano-Tech and Nano-Bionics, Soochow University, South China University of Technology, and Central South University have all been conducting foundational research on OPV printing technologies for many years.

Central South University has made significant advancements by developing a combined roll-to-roll gravure printing and roll-to-roll slot-die coating technology for OPV manufacturing. This innovation has expanded the range of available OPV printing methods.

Shanghai MiFang Technology primarily uses inkjet printing technology combined with blade coating for their production process. This method addresses two major challenges faced by current OPV technology: relatively low power conversion efficiency and the difficulty in achieving the stability of mature photovoltaic products. By leveraging the advantages of inkjet printing’s graphic and personalized printing capabilities, they custom-manufacture OPV devices using desktop inkjet printers.

Encouragingly, with the rise of non-fullerene acceptor materials and triplet-state OPV device structures, Chinese researchers have made significant world-leading advancements. Recently, in August 2018, Professor Chen Yongsheng’s team from Nankai University designed and produced tandem organic solar cell materials and devices with high efficiency and broad-spectrum absorption characteristics, achieving a conversion efficiency of 17.3%. This set a new world record for the power conversion efficiency of organic solar cells.

Definition of the Organic Photovoltaics (OPV) Industry

Organic Photovoltaics (OPV) is a type of solar cell technology that uses organic materials for the conversion of sunlight into electricity. Unlike traditional silicon-based photovoltaic technology, OPV utilizes organic molecules or polymers with semiconductor properties as the light-absorbing and charge-transport layers.

The working principle of OPV involves organic materials absorbing sunlight, which generates electron-hole pairs (positive and negative charges). These charges are then separated under the influence of an electric field, allowing them to flow through the electrodes, generating electrical current. Organic materials are typically more cost-effective, flexible, transparent, and versatile, offering broader application potential.

However, compared to silicon-based solar cells, OPV has lower efficiency, and its stability and lifespan need improvement. Research institutions and companies are actively working to enhance OPV technology by improving its efficiency, stability, and commercial viability. Potential applications include building-integrated photovoltaics, wearable devices, and flexible electronics.

Material Classification:

- Small Molecule Organic Photovoltaics (SM-OPV):

This type of OPV uses small organic molecules as the light-absorbing and charge-transport layers. Small molecules typically allow for precise control over the molecular structure, leading to potential improvements in efficiency and performance. - Polymer Organic Photovoltaics (Polymer-OPV):

In this category, organic polymers are used as the light-absorbing and charge-transport layers. Polymers offer flexibility, low-cost production, and the ability to create large-area, flexible solar panels, making them suitable for a variety of applications.

- Single-layer Structure:

In this structure, the light-absorbing and charge-transport layers are combined into a single layer. This is a simpler design but may result in lower efficiency due to less effective charge separation. - Bilayer Structure:

In a bilayer structure, the light-absorbing layer and the charge-transport layer are separated into two distinct layers. This allows for more efficient charge separation and transport, leading to potentially higher performance. - Blend Structure (Bulk Heterojunction):

In this structure, the light-absorbing and charge-transport materials are mixed together within a single layer. This configuration allows for efficient charge separation and collection, enhancing the overall efficiency of the OPV device.

- Transparent OPV:

Transparent OPV refers to OPV devices that exhibit high transparency, making them suitable for applications on windows, building facades, and other transparent materials. These devices allow light to pass through while generating electricity. - Flexible OPV:

Flexible OPV devices are designed to be flexible and bendable, making them suitable for applications in wearable devices, smart tags, and other flexible electronics. They offer versatility and can conform to various shapes and surfaces without compromising their functionality.

Advantages of the Organic Photovoltaics (OPV) Industry

- Low Cost: Compared to traditional silicon-based solar cells, OPV utilizes organic materials that are typically less expensive to manufacture. This translates to more cost-effective production processes, potentially lowering overall solar energy system costs.

- Flexibility and Versatility: Organic materials used in OPV can be processed in flexible forms, allowing OPV to adapt to various shapes and curved surfaces. This makes them suitable for applications in wearable devices, smart tags, and other areas requiring flexibility.

- Low Light Intensity Performance: OPV can operate effectively under low light conditions, maintaining its energy conversion efficiency even in indoor lighting or shaded environments. This capability gives OPV an advantage in areas with limited sunlight exposure.

- Environmentally Friendly: The organic materials used in OPV are relatively environmentally friendly. The manufacturing process generates less waste and emissions compared to traditional solar cell production methods, reducing environmental impact.

Disadvantages of the Organic Photovoltaics (OPV) Industry

- Relatively Low Efficiency: Currently, OPV technology has lower conversion efficiency compared to silicon-based solar cells. This limits OPV’s competitiveness in large-scale commercial applications where high efficiency is crucial.

- Stability and Lifespan: OPV devices exhibit shorter stability and lifespan due to their susceptibility to environmental factors such as light exposure, humidity, and temperature variations. Improvements in materials and device structures are necessary to enhance long-term stability.

- Size Limitations: Organic materials used in OPV have lower absorption coefficients, limiting the depth of light penetration. As a result, OPV devices typically require thicker layers to achieve sufficient light absorption, which increases their thickness and weight.

- Early-stage R&D and Industry Development: Compared to traditional silicon-based solar cell technology, the commercial development of OPV is still in its early stages. Research and development efforts, as well as the industrial supply chain, are relatively nascent and require further advancement.

Organic Photovoltaics (OPV) Technology Transforming Renewable Energy

With advancements in Organic Photovoltaics (OPV) technology, two key visions are becoming reality. OPV, based on organic materials, offers a thinner, lighter, and more flexible alternative to traditional silicon-based solar cells. This versatility allows OPV to be manufactured in various shapes and sizes, potentially revolutionizing how we produce and utilize renewable energy.

In recent years, the demand for sustainable and energy-efficient buildings has been rising. Transparent OPV provides a perfect solution for this challenge. These organic solar cells can be made highly transparent and can even be tinted in various colors. Such glass maintains excellent transparency indoors while collecting solar energy for electricity generation outdoors. This technology not only promotes smarter, more efficient, and eco-friendly energy use but also enhances aesthetic and design values in architecture.

Among known photovoltaic materials, OPV stands out for its transparency and color diversity. Unlike crystalline silicon cells that are typically opaque in blue, gray, or black, or perovskite cells that have limited color variations due to their crystal structures, OPV can be engineered to absorb and emit a wider range of wavelengths by controlling molecular structures and chemical compositions. This advantage makes OPV particularly attractive for applications requiring diverse color options.

OPV cells can be manufactured on PET substrates, enabling the production of large-area, ultra-thin, truly flexible solar panels. This flexibility surpasses that of cadmium telluride and copper indium gallium selenide flexible PV cells, which are typically mounted on thin stainless steel substrates. OPV’s flexibility allows it to conform perfectly to curved surfaces, facilitating customized designs and production. Unlike traditional solar panels that require mounting brackets, flexible OPV solar cells can be directly installed on building surfaces such as walls, roofs, and windows, saving space and enhancing architectural aesthetics.

These features position OPV technology at the forefront of building integration and other innovative applications, offering new possibilities for the widespread adoption and utilization of renewable energy.

OPV Solar Panels: Efficiency and Performance in Building Integration

When it comes to efficiency, OPV solar cells maintain consistent electricity generation rates on building facades. In contrast, crystalline silicon cells experience significant efficiency drops on vertical surfaces, making them unsuitable for Building Integrated Photovoltaics (BIPV) applications. Unlike traditional PV systems, the installation angle has no impact on OPV’s electricity generation. This means OPV maintains its efficiency whether installed on building facades or non-south-facing roofs.

OPV solar panels exhibit strong performance in low-light conditions, generating electricity even on cloudy or rainy days. With an average daily generation time exceeding 6 hours, OPV outperforms crystalline silicon cells by twice the average generation time. Therefore, OPV is particularly suitable for regions with limited sunlight resources.

OPV: The Ideal Indoor Photovoltaic Solution

Organic Photovoltaics (OPV) stands out as the optimal indoor photovoltaic solution. Unlike crystalline silicon solar cells, which primarily rely on sunlight for electricity generation, OPV efficiently utilizes indoor light sources. OPV has achieved indoor conversion efficiencies exceeding 25%, whereas crystalline silicon cells typically achieve only around 5% under indoor lighting conditions.

In addition to superior indoor performance, OPV utilizes organic polymer materials, unlike perovskite components that may contain soluble lead elements unsuitable for indoor and human use. OPV’s organic materials offer a broader and more cost-effective supply chain compared to silicon-based solar cells, potentially reducing costs significantly with scale production. Furthermore, OPV manufacturing processes use environmentally friendly solvents and do not require heavy metal additives like lead, minimizing environmental pollution.

OPV represents a more environmentally friendly, efficient, and durable renewable energy technology with enhanced flexibility. It is suitable for various indoor applications such as low-power appliances and wearable devices, potentially replacing traditional button cells and AA batteries. For instance, OPV can be applied in low-light indoor environments for wireless sensors, smart home devices, and smart tags.

The EPFL Solar Pavilion in Switzerland, the PowerWindow project in the Netherlands, and the Heliatek OPV pilot project in Germany demonstrate the feasibility and potential of transparent organic photovoltaic (OPV) technology in building-integrated photovoltaics (BIPV) applications. The “OeMega” series of architectural OPV products launched by Armor is a flexible organic photovoltaic film that can be applied to building facades, roofs, windows, and other surfaces.

The commercialized colors of OPV typically include light blue, light purple, and gray, as well as transparent OPV products. These colors are primarily a result of the selection of organic molecules and the composition of the materials.

As a leading mass-production OPV company in the Greater China region, Guangzhou Carbon Valley Technology has outpaced European companies by leveraging China’s advantages in the photovoltaic supply chain. The company’s products are widely applicable in BIPV distributed photovoltaic buildings, new energy vehicles, photovoltaic agricultural greenhouses, as well as consumer electronics and the Internet of Things. The company has already shipped small batch orders, and several demonstration projects are currently under construction.

Under indoor lighting conditions, OPV (organic) photovoltaics can power electronic paper applications, replacing button batteries or AA and AAA batteries. Especially in light of the EU’s stringent battery policies, OPV (organic) photovoltaics emerge as the optimal indoor lighting solution, poised for explosive growth alongside the use of electronic paper.

The company’s OPV batteries can supply power to electronic paper. These OPVs are being applied in logistics management, retail electronic tags, and medical management, helping businesses improve efficiency and accuracy.

In outdoor lighting conditions, the company’s OPV batteries can power large electronic paper displays, such as outdoor billboards and large display applications. Meanwhile, the company’s OPV photovoltaic walls, photovoltaic windows, and shipping container solar power system demonstration projects are under construction, providing sustainable energy solutions for the construction and logistics industries.

The company’s OPV photovoltaic batteries are also being tested in collaboration with automotive companies for applications as rooftop power-generating glass.

Furthermore, the company’s OPV photovoltaic batteries have garnered significant attention in the field of photovoltaic agricultural greenhouses. Through deep collaboration with agricultural partners, the company is conducting sample tests for multiple photovoltaic agricultural greenhouse power generation systems. OPV can enhance crop yield by adjusting the battery colors, improving the efficiency of photovoltaic agriculture and providing reliable electricity supply solutions for rural areas, contributing to rural revitalization.

The company’s OPV photovoltaic batteries are also being integrated into the design of power supply solutions for 5G base stations, offering reliable energy support for this high-tech sector.

Development History of Organic Photovoltaics (OPV)

In the late 1970s to early 1980s, academia began exploring the application of organic materials in the photovoltaic field. In 1986, Tang and VanSlyke first reported organic polymer-based light-emitting diodes (LEDs), marking the rise of organic electronics. In 1992, Donald L. Gorzynski and others reported the first solar cells based on organic small molecules. Over the following years, significant breakthroughs were made in the academic community, including improvements in the efficiency of organic photovoltaic devices, advancements in interface engineering, and the development of photosensitive materials.

In 2005, Kodak launched the world’s first commercial organic photovoltaic product. That same year, organic small molecule photovoltaics achieved efficiencies exceeding 5%. In 2008, the American company Konarka Technologies announced the launch of flexible OPV products, applying them in the construction sector. By 2011, Heliatek became the first company in the world to commercially produce large-area organic solar cell modules. Over time, OPV technology has further improved efficiency and reduced costs, attracting growing interest from more companies and investors. Currently, OPV technology is widely applied in building integration, wearable devices, and smart labels, with the potential for gradual commercialization and large-scale deployment.

OPV Industry Supply Chain

The raw materials for organic photovoltaics (OPV) primarily consist of organic semiconductor materials, such as polymers and small organic compounds. OPV is applied in various industries, including building integration, wearable devices, and smart electronics. Despite facing challenges, OPV is considered a potential candidate for future solar cell technology due to its advantages of low cost, flexibility, and environmental friendliness.

The global organic photovoltaic market is expected to maintain a high growth rate in the coming years. However, the current global market size for organic photovoltaics remains relatively small, accounting for only a small portion of the solar energy market. As one of the largest solar markets in the world, China has shown significant interest in the development of organic photovoltaics. The country actively promotes research, development, and commercialization of OPV technology through policy support and funding initiatives, encouraging companies and research institutions to participate in this field. Several companies and research institutions focused on organic photovoltaic technology have emerged in China. Some of these companies are engaged in the R&D and production of OPV products and are collaborating with sectors such as construction, automotive, and smart electronics.

According to data from the China Photovoltaic Industry Association, China’s photovoltaic industry is projected to achieve stable growth in 2021. The production of polysilicon, silicon wafers, battery cells, and modules reached 505,000 tons, 227 GW, 198 GW, and 182 GW, respectively, with year-on-year growth rates of 28.8%, 40.7%, 46.9%, and 46.1%. The total output value of these four compounds exceeded 750 billion yuan. At the same time, the industry’s concentration has further increased. In the four key areas of polysilicon, silicon wafers, battery cells, and modules, the top five manufacturing enterprises accounted for 86.7%, 84%, 53.9%, and 63.4% of the total domestic output, respectively, indicating significant economies of scale among the leading companies.

The market size of China’s organic photovoltaics (OPV) industry has maintained steady growth in recent years. According to data from the China Energy Storage Network, the market size reached 1.136 billion yuan in 2020, representing a year-on-year increase of 10%. In the coming years, the OPV industry in China is expected to continue growing, especially against the backdrop of increasing importance of renewable energy, which will present greater development opportunities for organic photovoltaics.

Challenges in the OPV Industry

- Conversion Efficiency: Currently, the conversion efficiency of OPV remains relatively low, significantly lower than that of traditional silicon-based solar cells. While OPV performs well under low light conditions, there is still room for improvement under high light conditions. Enhancing conversion efficiency is crucial for commercial promotion and competition.

- Stability and Lifespan: OPV devices generally exhibit relatively short stability and lifespan, making them susceptible to environmental factors such as light, humidity, and temperature, which can lead to performance degradation and decreased durability. This limits the reliability and longevity of OPV in practical applications.

- Material Costs and Supply Chain: The organic materials used in OPV can be relatively expensive, and the production processes and costs of some materials require further improvement. Additionally, the stability and sustainability of the supply chain are critical issues, especially for large-scale commercial applications.

- Commercial Scale and Market Recognition: OPV technology is still in its early development stage, with relatively small commercial scale. Given the dominance of traditional silicon-based solar cells, OPV needs to gain market recognition and prove its competitiveness in terms of cost, efficiency, and reliability.

- Size Limitations and Integration: Due to the low light absorption coefficient of organic materials, OPV typically requires a relatively large thickness to achieve ideal light absorption. This limitation impacts the size and integration of devices, particularly in applications such as wearable devices and smart electronics.

Development Prospects of the Organic Photovoltaic (OPV) Industry

- Technological Improvements: As technology continues to advance and R&D investments increase, the key performance indicators of OPV—such as conversion efficiency, stability, and lifespan—are expected to improve significantly. The development of new materials and the optimization of device structures are likely to propel OPV technology toward greater efficiency and reliability.

- Expansion of Commercial Scale: With the maturation of OPV technology and the progress of commercialization, its market size is expected to gradually expand. Particularly in applications such as building integration, wearable devices, and the Internet of Things, the flexibility and lightweight characteristics of OPV will provide it with unique advantages that could lead to widespread adoption.

- Growing Demand for Sustainable Energy: There is a rising global demand for sustainable energy, along with increased interest in environmentally friendly solar solutions. As a relatively low-cost, flexible, and eco-friendly solar technology, OPV is well-positioned to meet this demand and play a significant role in future energy markets.

It is important to note that the OPV industry is still in its early development stage, facing challenges related to conversion efficiency, stability, and material costs. Therefore, predictions about its development prospects should be made cautiously, considering the potential for technological innovation and shifts in market demand. However, overall, OPV shows great promise as a viable solar technology, with the potential for significant breakthroughs and applications in the coming years.

The industrialization of OPV has experienced two major shocks in its development process. The first shock was caused by the oversupply of crystalline silicon solar cells, which led to a dramatic decline in photovoltaic prices. Even printed OPV, due to its low efficiency and short lifespan, was unable to compete with crystalline silicon solar cells in the market. A notable example is the bankruptcy of Konarka Technologies, one of the earliest companies to use roll-to-roll printing methods for OPV. Nobel laureate A. Heeger was one of its partners. In 2010, the Power Plastic solar cells produced by Konarka achieved a certified conversion efficiency of 8.3% by the U.S. National Renewable Energy Laboratory (NREL), later reaching 8.8% to 9.0% in 2012. Despite Konarka’s commendable achievements and substantial venture capital and government funding, the company struggled to achieve profitability due to poor market development and declared bankruptcy in June 2012. In October 2012, Konarka’s German subsidiary was acquired by a German solar photovoltaic integration company and rebranded as Belectric OPV GmbH.

The second major shock for organic photovoltaics was the emergence of perovskite solar cells, which caused some research institutions initially focused on OPV to shift their focus to developing perovskite photovoltaics. As a result, OPV industrialization projects received less attention in the capital market. However, with the gradual increase in the photovoltaic conversion efficiency of OPV, the industry is starting to recover from the lows following Konarka’s bankruptcy. This recovery is likely to stimulate significant market demand, attracting many researchers and companies into the field of printed OPV. It will also provide new development opportunities for printing technology in the photovoltaic sector.