Revolutionary Technology: Mass Production of Defect-Free Graphene Foil to Transform Battery Safety!

In lithium-ion batteries (LIBs), thermal runaway is a critical safety concern. When the heat generation rate within the battery surpasses its cooling capacity, localized temperatures can spike rapidly, triggering a chain reaction. This issue commonly arises during high-power output, overcharging, external heating, or mechanical damage, intensifying internal chemical reactions and further generating heat. Traditional current collectors made of metals like aluminum and copper, with relatively low thermal conductivity (200-400 W/mK), often fail to dissipate heat effectively, especially in high-energy-density batteries. This leads to localized heat buildup, which can cause electrolyte decomposition, gas generation, and, in severe cases, catastrophic fires or explosions.

Managing Thermal Runaway in Batteries

Managing and controlling internal heat is crucial for enhancing battery safety. Several methods are employed to prevent thermal runaway in LIB design:

- Effective thermal management systemsmonitor and regulate battery temperatures, preventing localized overheating.

- Battery management systems (BMS)track voltage, current, and temperature, taking actions like cutting off power or cooling the battery when abnormalities are detected.

- Optimized battery structure designprevents localized heat buildup, reducing the risk of thermal runaway.

Additionally, using materials with high thermal conductivity, such as graphene, can significantly improve heat dissipation, lowering the risk of thermal runaway.

Breakthrough in Graphene Foil Technology

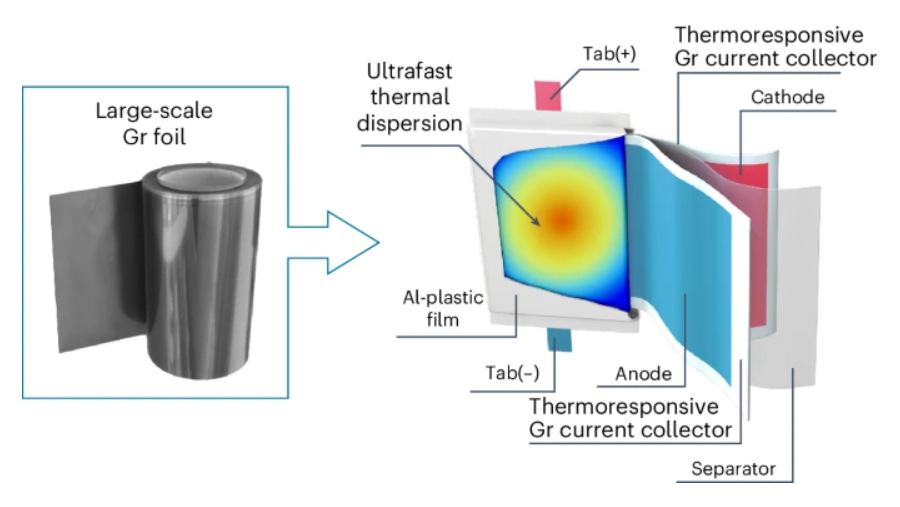

In a groundbreaking development, Professors He Daping and Mai Liqiang from Wuhan University of Technology, along with Professor Yang Jinlong from Shenzhen University, have pioneered a non-metallic current collector based on graphene, enabling the mass production of graphene current collectors. This breakthrough could significantly enhance the safety and performance of LIBs, addressing a major challenge in energy storage technology. Moreover, this is the first successful commercial-scale production of defect-free graphene foil.

This advancement is poised to revolutionize battery safety and efficiency, providing a robust solution to the longstanding issue of thermal management in high-performance batteries.

Graphene’s π-π Interlayer Interactions and Highly Ordered Stacking Structure: Enhancing Thermal Conductivity

The π-π interlayer interactions and highly ordered stacking of graphene enable it to efficiently propagate phonons, significantly boosting its thermal conductivity. In the study, the graphene foil exhibited an exceptionally high thermal conductivity of 1400.8 W·m⁻¹·K⁻¹—an order of magnitude higher than traditional aluminum and copper foils. This graphene current collector can effectively dissipate heat and prevent the exothermic reactions that lead to thermal runaway. The dense, well-aligned graphene structure acts as a robust barrier, preventing the formation of flammable gases and the penetration of oxygen into the battery cells, which is critical for avoiding catastrophic failures.

Enhancing Battery Safety and Performance

Integrated with temperature-responsive foils, LiNi₀.₈Co₀.₁Mn₀.₁O₂ || graphite batteries showed significantly faster heat dissipation, eliminating localized heat accumulation and preventing aluminum heat and hydrogen release reactions that could lead to thermal runaway in lithium-ion battery packs. This process removes critical factors that contribute to thermal failures in batteries, reducing the risk of accidents.

Mass Production of Customizable Graphene Foil

The newly developed process allows for the production of graphene foil in lengths ranging from meters to kilometers, with customizable thicknesses, making batteries more efficient and safer. To demonstrate its potential, researchers produced a 200-meter-long graphene foil with a thickness of 17 micrometers. Even after being bent more than 100,000 times, the foil maintained its high electrical conductivity, making it ideal for flexible electronics and advanced applications.

This breakthrough could have a profound impact on the future of energy storage, especially in electric vehicles and renewable energy systems, offering a more efficient and safer solution for high-performance batteries.

Key Applications of Graphene Foil

- Lithium-Ion Batteries:The high thermal conductivity of graphene foil significantly enhances thermal management in batteries, maintaining stable operating temperatures under high load and temperature conditions. This is crucial for applications requiring high energy density and safety, such as electric vehicles and high-performance portable electronics. Additionally, the lightweight nature of graphene foil can improve battery energy density, extending device runtime.

- Redox Flow Batteries:In large-scale energy storage systems, graphene foil boosts efficiency and reliability. Its high thermal conductivity helps manage heat within the battery stack, extending system lifespan and reducing maintenance costs.

- Electrolyzers and Fuel Cells:Graphene foil can be used as electrode material or current collector in electrolyzers and fuel cells, enhancing electrical conductivity and thermal management. The high surface area and excellent electrochemical stability of graphene make it highly effective for improving energy conversion efficiency and reducing energy consumption in these applications.

- Electronic Devices and Electric Vehicles:As the demand for high-performance batteries grows in electric vehicles and portable electronics, graphene foil’s application potential is expansive. It not only increases battery energy density and charge/discharge rates but also significantly improves safety by reducing the risk of fire or explosions.

- Multifunctional Energy Storage Systems:The flexibility and durability of graphene foil make it suitable for energy storage systems that undergo frequent charging and discharging and endure high mechanical stress. It maintains stable performance under extreme conditions, making it ideal for aerospace, grid storage, and military applications where safety and reliability are critical.

Summary: Graphene foil, with its unique physical and chemical properties, shows immense potential across various energy storage and electrochemical applications. Its advantages in enhancing battery safety, energy density, thermal management, and sustainability make it a key material for future high-performance battery and energy storage technologies. As production technology advances, graphene foil is expected to play a critical role in broader industrial applications.