Revolutionize Your Projects with Graphene Coatings – Applications, Advantages, and Market Potential

In this article, we’ll explore the costs, benefits, and transformative potential of graphene coatings—an innovative material solution that’s redefining industries from construction to electronics. Whether you’re a product developer, engineer, or business owner, understanding how graphene coatings can add value to your application is key to staying competitive.

If you’ve heard the buzz around graphene coatings and wondered whether they live up to the hype, you’re not alone. As industries demand more durable, conductive, and multifunctional coatings, graphene has emerged as a standout nanomaterial. But is it just a futuristic concept, or is it already reshaping real-world products?

Whether you want to enhance your product’s performance, reduce maintenance cycles, or break into high-tech markets, graphene coatings may offer exactly the edge you need. With unparalleled strength, conductivity, and barrier properties, graphene can outperform traditional additives and opens the door to new generations of smart coatings.

What Are Graphene Coatings?

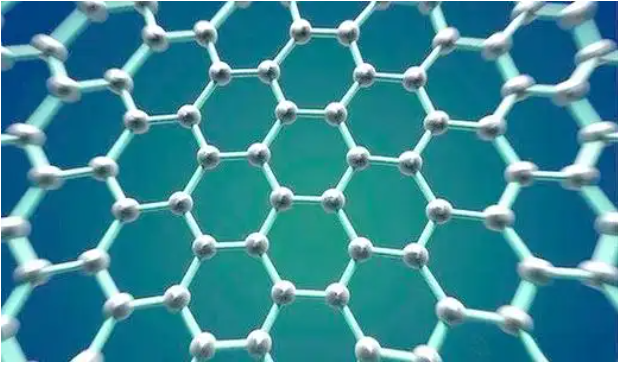

Graphene coatings are protective or functional layers that integrate graphene—a single layer of carbon atoms arranged in a hexagonal lattice—into a resin or paint matrix. These coatings can be applied on metals, plastics, textiles, and composites to enhance performance across a wide range of applications.

The core appeal lies in graphene’s multifunctionality: it is ultra-strong, thermally and electrically conductive, chemically stable, and impermeable to gases and liquids. When integrated properly into a coating, even at very low loading levels, it offers superior performance without drastically altering the host material’s properties.

Graphene Coating Applications in 2025

1. Corrosion Protection for Industrial Infrastructure

Graphene-enhanced anti-corrosion paints offer a major improvement over conventional zinc-based primers. A single coat can significantly extend the service life of steel structures in harsh environments like offshore platforms, bridges, and pipelines.

2. Thermal Management in Electronics

Graphene-based thermal interface coatings efficiently dissipate heat in devices such as smartphones, CPUs, and LED panels. These coatings improve reliability and allow for higher performance in compact designs.

3. Conductive Coatings for Smart Textiles

Textiles treated with graphene inks or sprays can become conductive while maintaining breathability and flexibility. These are being used in smart clothing, sensors, and wearable medical devices.

4. Anti-Static and EMI Shielding for Automotive and Aerospace

Graphene coatings provide lightweight yet effective electromagnetic interference (EMI) shielding and anti-static protection, critical in sensitive electronic modules used in electric vehicles and aircraft.

5. Anti-Fouling and Antimicrobial Coatings

The addition of graphene oxide in marine paints and medical device coatings helps inhibit microbial growth and prevent biofouling, extending the life of ships, implants, and water filtration units.

Is Investing in Graphene Coatings Worth It?

The Cost vs. Value Debate

Graphene coatings typically command a premium over conventional coatings, mainly due to material synthesis costs. However, the value they offer—such as reducing corrosion-related downtime, enabling next-gen devices, or lowering maintenance cycles—can more than justify the investment.

Mass production and the emergence of cost-effective graphene dispersions are narrowing the price gap. For high-value sectors like aerospace, medical, or advanced electronics, the return on investment (ROI) can be substantial.

The Business Potential of Graphene Coatings

Profit Potential for Manufacturers and Resellers

By incorporating graphene into your product line—whether it’s industrial paints, automotive parts, or flexible electronics—you can offer differentiated solutions that command higher margins. Companies like Tesla and Boeing are already exploring such innovations.

Niche Applications Driving Growth

The combination of strength, flexibility, and conductivity means graphene coatings are being adopted in niche but fast-growing markets like EV batteries, printed electronics, hydrogen fuel cells, and fire-resistant materials.

Global Market Access

Due to their eco-friendly and high-performance nature, graphene coatings also align well with global sustainability goals, opening doors in Europe, North America, and Asia for companies looking to stand out in “green innovation.”

Is Graphene Coating Just Hype or a Game-Changer?

For DIY Enthusiasts and R&D Labs

If you’re a hobbyist or a research lab, using graphene-based sprays and resins for custom projects can yield fascinating results—from conductive drone components to self-healing composites. Small-scale use is accessible and growing thanks to dispersion kits and ready-to-use formulations.

For Industrial Producers and Startups

Those looking to scale products with unique performance traits will find graphene coatings a strategic differentiator. With the right partners and technical know-how, you can enter markets that previously required complex material systems.

Graphene Coating Integration: Is It Difficult?

Ease of Use and Processing

Modern graphene dispersions are compatible with common solvents, resins, and waterborne systems. They can be blended into existing coating lines with minimal adjustments. Formulating does require attention to dispersion stability and particle size, but suppliers now offer pre-formulated concentrates for plug-and-play use.

Learning Curve

For formulators, understanding the interaction between graphene and your matrix—such as epoxy, polyurethane, or acrylic—is crucial. However, industry-wide knowledge and academic research have made it easier than ever to access technical support, case studies, and sample recipes.

Maintenance and Longevity of Graphene-Enhanced Products

Graphene’s barrier properties significantly slow down moisture and oxygen ingress, meaning coated surfaces resist corrosion, delamination, and microbial attack far better than traditional coatings. This translates into longer-lasting infrastructure, electronics, and consumer products, ultimately lowering lifecycle costs.

Periodic reapplication might be needed depending on the host environment, but the intervals are often much longer than with standard coatings.

Portable vs. Industrial Use: Which One Suits You?

Small Batch or R&D?

Portable spray kits or brush-on graphene coatings are ideal for small-scale prototyping, educational demonstrations, and experimental applications.

Industrial Coating Lines

For mass production, graphene coatings can be integrated into roller-coating, dip-coating, or electrostatic spray lines with suitable modifications. Industrial-grade dispersions can also be used in resin casting, powder coating, or inkjet applications.

Creative Ways to Use Graphene Coatings for Business

Custom Coated Products

-

Fire-resistant furniture and building panels

-

Wearable tech fabrics with embedded circuits

-

Graphene-coated helmets and protective gear for enhanced impact resistance

Value-Added Industrial Coatings

-

Smart anti-corrosion systems for oil & gas pipelines

-

Conductive floor coatings for ESD-safe environments

-

Transparent conductive coatings for displays and solar panels

Eco-Friendly Coating Solutions

-

Low-VOC waterborne graphene coatings for architectural use

-

Bio-based graphene composites for packaging and agriculture

-

Marine-grade coatings that reduce chemical leaching

Should You Invest in Graphene Coatings?

If you’re in the business of innovation, the answer is likely yes. Graphene coatings are not only futuristic—they’re functional today. They offer high performance, multi-industry relevance, and strong economic returns when applied to the right use case.

Yet, the decision depends on your needs, application scale, and product lifecycle goals. For some, outsourcing coating services or testing with sample kits may suffice. For others, adopting graphene into the production line could be the differentiator between mediocrity and market leadership.

Graphene Coatings aren’t just science fiction—they’re your next strategic advantage.

Ready to explore graphene coatings for your next project? Contact Ningbo GrapheneRich NanoTech at graphenerich.com to get started with customized solutions, dispersions, and technical support tailored to your industry