Safety & Certification — Why Graphene Heating is Safer (No “Hot Spots”)

As graphene heating films gain popularity in EV battery packs, smart floors, wearable textiles, and household appliances, safety has become a top priority for OEMs and system integrators. Traditional resistive heating methods—like nichrome wires, carbon fiber mats, and PTC elements—can produce uneven heating or “hot spots” that compromise user comfort, product longevity, and safety certification compliance.

Graphene heating films inherently reduce these risks due to their ultra-uniform conductivity, flexible structure, and advanced production quality control. This article explains why graphene heating solutions are safer, how their performance supports global safety standards, and how OEMs can leverage certified graphene films to simplify product approvals.

1️⃣ Understanding the “Hot Spot” Problem

What is a Hot Spot?

A hot spot occurs when local regions of a heating element experience higher current density, resulting in:

-

Excessive local temperature

-

Material degradation

-

Electrical insulation breakdown

-

Increased fire risk

Traditional heating technologies are prone to hot spots because:

-

Wires or strips have discrete conductive paths

-

Carbon fiber mats can have variable density

-

PTC elements respond only after overheating occurs, not preemptively

For sensitive applications like EV battery pre-heating, wearable garments, and underfloor heating, hot spots are unacceptable.

2️⃣ How Graphene Heating Films Solve Hot Spot Issues

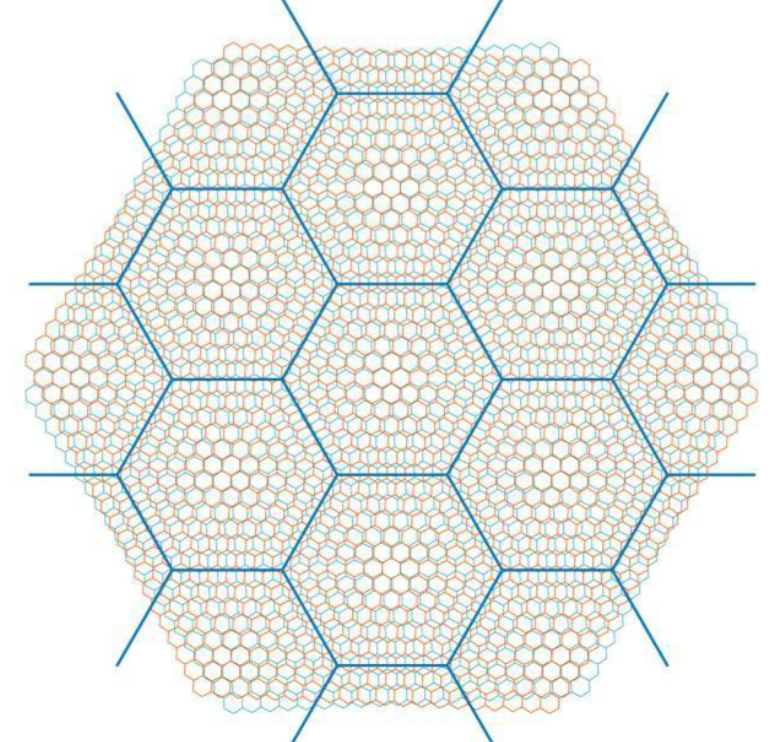

Graphene heating films are 2D conductive sheets made of single-layer or multi-layer graphene nanosheets embedded or laminated on flexible substrates (PET, PI, TPU, Fe-Al). Their key properties that prevent hot spots include:

2.1 Uniform Sheet Resistance

-

Graphene’s intrinsic conductivity allows for a homogeneous electrical path

-

Current spreads evenly across the entire film, preventing local overheating

2.2 High Thermal Conductivity

-

Graphene’s thermal conductivity (500–1500 W/m·K) ensures fast lateral heat spreading

-

Minor variations in current are smoothed out naturally, keeping temperature differences within ±2 °C

2.3 Flexible Substrate Integration

-

Films bend, fold, or conform to irregular surfaces without creating stress points

-

This reduces risk of cracks or localized current concentration

2.4 Advanced Etching & Printing Techniques

-

Laser or chemical etching allows precise heating zone definition

-

Customized patterns ensure uniform voltage distribution

Together, these factors eliminate the primary causes of hot spots seen in older heating technologies.

3️⃣ Safety Certifications and Compliance

Graphene heating films are designed for international compliance, which is critical for OEMs exporting globally.

3.1 Common Certifications

| Certification | Purpose |

|---|---|

| CE (EU) | Electrical safety, EMC compliance, RoHS environmental standards |

| UL (North America) | Safety testing for insulation, fire resistance, and electrical load |

| IEC / ISO Standards | Global quality and performance benchmarks |

| EMC / EMI Compliance | Ensures heating films don’t interfere with electronics (especially in EVs) |

3.2 Testing Protocols

-

Thermal imaging to confirm uniform heating

-

Insulation resistance (>100 MΩ)

-

Dielectric strength testing

-

Mechanical fatigue tests (10,000+ bending cycles)

-

Waterproof / IP rating tests

-

Overheat protection verification

These tests ensure the heating film maintains safety under long-term operation, even in extreme temperatures or harsh environments.

4️⃣ Advantages Over Traditional Heating Methods

| Feature | Graphene Heating Film | Nichrome Wire / PTC |

|---|---|---|

| Hot spot risk | Extremely low | Medium to high |

| Uniform temperature | ±2 °C | ±5–10 °C |

| Flexibility | High, conforms to surfaces | Low, rigid wires or strips |

| Safety under bending | Excellent | Poor (risk of wire break) |

| Energy efficiency | High | Medium |

| Fast response | Seconds | Tens of seconds |

Graphene films achieve stable, low-voltage operation and distributed heat generation, ensuring user safety while improving energy efficiency.

5️⃣ Applications Where Safety Matters Most

A. EV Battery Packs

-

Even small temperature variations can trigger lithium plating or thermal runaway

-

Graphene heating films maintain cell-to-cell uniformity and prevent local overheat

B. Smart Floor Heating

-

Eliminates hot tiles or uneven warming

-

Safe for direct contact with feet or children

C. Wearable Heating

-

Maintains uniform heat on garments and medical pads

-

Prevents burns or discomfort during prolonged use

D. Appliances & Industrial Equipment

-

Heaters for tea warmers, mirrors, and industrial panels benefit from reduced fire risk

-

Enhanced insulation and film uniformity improve reliability

6️⃣ Best Practices for OEMs

To maximize safety benefits:

-

Select certified graphene films with verified uniformity

-

Integrate NTC/PTC sensors for overheat protection

-

Follow manufacturer wiring & layout guidelines to prevent stress points

-

Avoid folding/creasing films beyond specified limits

-

Test with thermal cameras to validate uniformity before production

OEMs who follow these practices gain regulatory confidence, faster certification, and superior product reliability.

7️⃣ Why Certified Graphene Heating Films Simplify Product Approval

Using pre-certified graphene films can:

-

Reduce in-house safety testing

-

Shorten time-to-market for EV, appliance, or wearable products

-

Ensure compliance with multiple global standards simultaneously

-

Build trust with downstream integrators and end-users

This is especially valuable for SME clients and small-volume OEMs, who may lack extensive in-house testing capabilities.

8️⃣ Conclusion

Graphene heating films provide a safer, more reliable, and more efficient alternative to traditional resistive heaters. By combining:

-

Uniform electrical conductivity

-

High thermal spreading

-

Flexible, durable substrates

-

Proven international certifications

Graphene films eliminate hot spots, reduce fire risk, and simplify global regulatory compliance. OEMs, integrators, and contractors can confidently adopt graphene heating films for EVs, smart floors, wearables, appliances, and industrial applications, ensuring safety, comfort, and long-term performance.