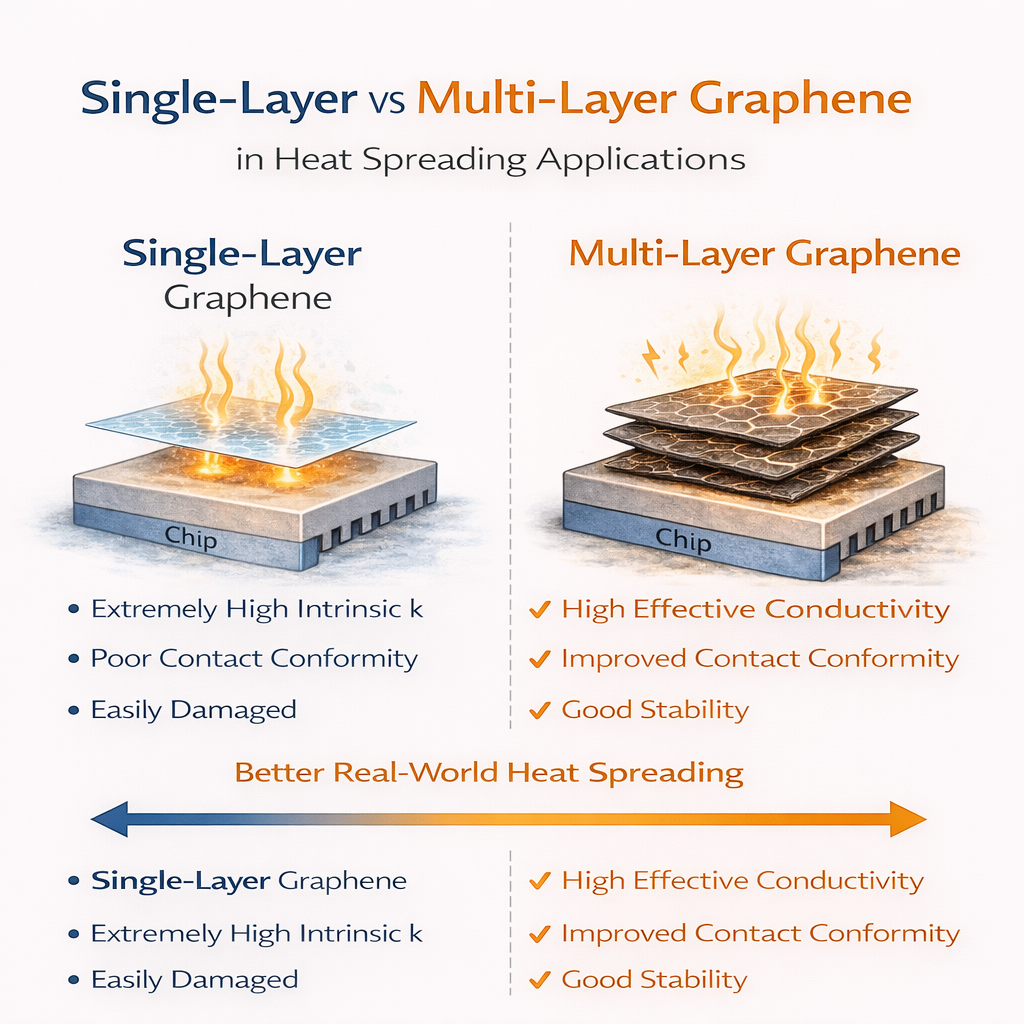

Single-Layer vs Multi-Layer Graphene in Heat Spreading Applications

1. Why Heat Spreading Is Different from Heat Conduction

In thermal management, heat spreading and heat conduction are often mixed up—but they solve different problems.

-

Heat conduction: moving heat from point A to point B

-

Heat spreading: distributing localized heat over a larger area to reduce hot spots

Heat spreading is critical in:

-

Power electronics

-

Battery modules

-

LEDs

-

Chip-level and module-level thermal design

Graphene, with its exceptional in-plane thermal conductivity, is a natural candidate—but single-layer and multi-layer graphene behave very differently in real systems.

2. Structural Difference: One Atomic Layer vs Layered Networks

2.1 Single-Layer Graphene (SLG)

-

Thickness: ~0.34 nm

-

Perfect sp² carbon lattice

-

Extremely high intrinsic in-plane thermal conductivity

(theoretical values > 3000 W/m·K)

2.2 Multi-Layer Graphene (MLG)

-

Typically 3–20 layers (or more)

-

Interlayer van der Waals bonding

-

Slightly lower intrinsic in-plane conductivity per layer

-

Much higher mechanical robustness

Key insight:

In heat spreading applications, effective performance matters far more than theoretical material limits.

3. In-Plane Thermal Conductivity: Not the Whole Story

| Property | Single-Layer Graphene | Multi-Layer Graphene |

|---|---|---|

| Intrinsic in-plane k | Extremely high | Very high |

| Real-system utilization | Low | High |

| Sensitivity to defects | Extremely sensitive | More tolerant |

| Scale-up feasibility | Poor | Good |

Single-layer graphene achieves record numbers only under ideal, defect-free, suspended conditions.

In real coatings, films, or interfaces:

-

Grain boundaries

-

Wrinkles

-

Contact resistance

-

Substrate coupling

severely limit its advantage.

Multi-layer graphene forms overlapping conductive pathways, which often results in better macroscopic heat spreading.

4. Thermal Contact and Interfacial Effects

Heat spreaders never work alone—they sit between:

-

Heat source

-

Substrate

-

Encapsulant or TIM

Single-Layer Graphene:

-

Ultra-thin → poor contact conformity

-

Highly sensitive to surface roughness

-

Interfacial thermal resistance dominates

Multi-Layer Graphene:

-

Greater thickness improves surface contact

-

Lower sensitivity to micro-roughness

-

Reduced effective thermal contact resistance

➡ In most assemblies, interface resistance outweighs intrinsic graphene conductivity.

5. Mechanical Reliability and Processing Reality

5.1 Mechanical Stability

| Aspect | SLG | MLG |

|---|---|---|

| Handling | Extremely fragile | Robust |

| Crack tolerance | Very low | High |

| Thermal cycling | Poor | Good |

Single-layer graphene often fails during:

-

Coating

-

Lamination

-

Curing

-

Thermal cycling

Multi-layer graphene survives real manufacturing conditions.

5.2 Processability

Multi-layer graphene integrates better into:

-

Thermal coatings

-

Polymer matrices

-

Heat-spreading films

-

Hybrid CNT–graphene systems

Single-layer graphene typically requires:

-

Transfer processes

-

Cleanroom handling

-

High cost and low yield

6. Thickness vs Heat Spreading Efficiency

Heat spreading efficiency scales with:

-

In-plane conductivity

-

Lateral continuity

-

Film thickness

While SLG has the highest per-layer conductivity, its negligible thickness limits total heat flux capacity.

MLG provides:

-

Higher total heat transport capacity

-

Better lateral heat distribution

-

More stable performance over time

This is especially important in:

-

Battery thermal management

-

Power modules

-

Structural heat spreaders

7. Typical Application Matching

| Application | Preferred Graphene Type |

|---|---|

| Chip-scale experimental devices | Single-layer |

| Transparent heat spreaders | Few-layer |

| Coatings & paints | Multi-layer |

| Battery module heat spreading | Multi-layer |

| CNT–graphene hybrid networks | Multi-layer |

| Industrial thermal films | Multi-layer |

8. Cost, Supply Chain, and Scalability

-

Single-layer graphene:

-

High cost

-

Limited supply

-

Inconsistent quality at scale

-

-

Multi-layer graphene:

-

Mature production

-

Better batch consistency

-

Lower cost per performance unit

-

For industrial heat spreading, repeatability and scalability dominate material choice.

9. Design Takeaways for Engineers

-

Do not select graphene based on intrinsic k alone

-

Heat spreading depends on network continuity, not atomic perfection

-

Multi-layer graphene delivers better real-world performance

-

Interface resistance often dominates total thermal resistance

-

SLG is ideal for research; MLG is ideal for products

Single-layer graphene represents the upper theoretical limit of thermal transport—but multi-layer graphene delivers the best practical heat spreading performance.

In real thermal assemblies, where interfaces, roughness, and durability matter, multi-layer graphene consistently outperforms single-layer graphene at the system level.

This is why most commercial heat-spreading solutions rely on engineered graphene networks, not isolated atomic layers.