Single-Walled Carbon Nanotubes (SWCNTs) in Fire-Resistant Coatings: A Next-Generation Solution

Fire safety has become a pressing issue across industries such as construction, transportation, energy storage, and aerospace. Traditional flame-retardant coatings—based on halogenated compounds, mineral fillers, or intumescent paints—have been widely used for decades. While effective to some extent, they suffer from drawbacks such as toxicity, high weight, poor durability, and limited long-term performance.、

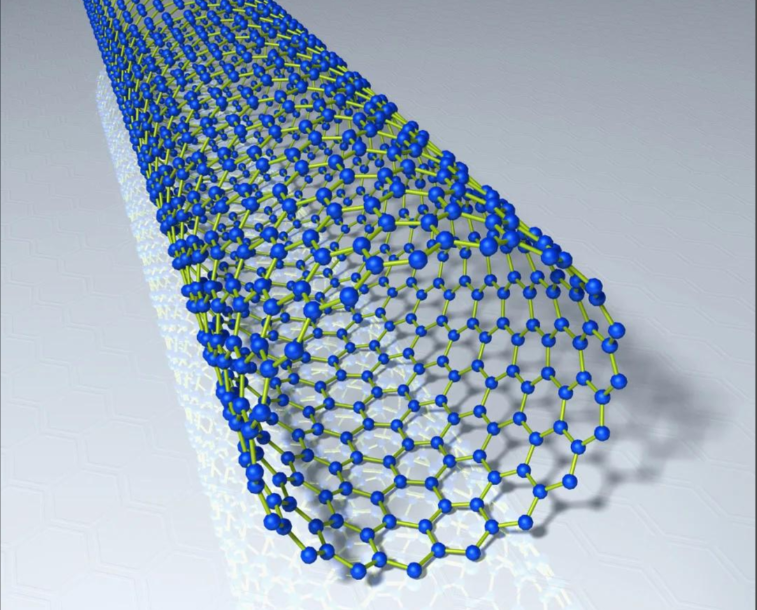

In recent years, nanomaterials have emerged as promising flame-retardant additives. Among them, single-walled carbon nanotubes (SWCNTs) are attracting significant attention. With their high aspect ratio, outstanding thermal stability, and electrical conductivity, SWCNTs offer a multifunctional pathway to improve fire-resistant coatings while also enhancing mechanical and conductive properties.

This article explores the mechanisms, advantages, applications, and commercialization challenges of using SWCNTs in fire-retardant coatings.

Why SWCNTs for Fire-Resistant Coatings?

SWCNTs are cylindrical nanostructures formed by rolling a single layer of graphene into a tube. Their unique structure grants them:

-

High Thermal Stability → Can withstand temperatures above 600–800°C.

-

Electrical Conductivity → Enables dissipation of heat and electromagnetic interference (EMI).

-

Mechanical Strength → Reinforces coatings, improving crack resistance.

-

Large Aspect Ratio → Creates highly effective barriers at very low loading (0.5–3%).

-

Lightweight Nature → Delivers performance without increasing coating bulk.

These properties make SWCNTs ideal candidates for multifunctional fire-retardant coatings that are lightweight, eco-friendly, and durable.

Mechanisms of Flame Retardancy with SWCNTs

SWCNTs improve fire resistance through several mechanisms:

-

Thermal Barrier Effect

-

SWCNTs form a dense network that slows down heat transfer.

-

Reduces the temperature rise in the underlying substrate.

-

-

Tortuous Path Effect

-

Creates a barrier that slows the diffusion of oxygen, flammable gases, and volatile products.

-

-

Char Formation Enhancement

-

Promotes the development of a stable char layer, insulating materials from heat and flame.

-

-

Synergy with Intumescent Systems

-

When combined with phosphorus-based intumescent coatings, SWCNTs increase foam stability and reduce flame spread.

-

-

Electrical Conductivity and Heat Dissipation

-

Conductive SWCNT networks help dissipate localized heat, lowering the risk of ignition.

-

Advantages of SWCNT-Based Fire-Resistant Coatings

-

High Efficiency at Low Loading → Only a few percent of SWCNTs can provide measurable flame-retardant benefits.

-

Lightweight and Thin → Unlike mineral fillers, SWCNTs do not require high concentrations, keeping coatings thin and lightweight.

-

Eco-Friendly Alternative → Free of halogens and toxic compounds.

-

Mechanical Enhancement → Improves adhesion, crack resistance, and wear resistance.

-

Multi-Functional Properties → Adds EMI shielding, antistatic behavior, and durability alongside fire protection.

Industrial Applications

1. Construction and Infrastructure

-

Steel structures, bridges, and tunnels can benefit from SWCNT coatings that combine fire resistance and corrosion protection.

2. Automotive and Electric Vehicles (EVs)

-

Battery packs, interiors, and underbody coatings require lightweight, flame-retardant systems.

-

SWCNT coatings can improve both fire safety and EMI shielding in EVs.

3. Aerospace and Aviation

-

Aircraft interiors demand lightweight, high-performance fire protection.

-

SWCNT-based paints provide safety without adding extra weight.

4. Marine and Offshore Structures

-

Ships and oil rigs need coatings that combine fire resistance, corrosion resistance, and durability.

-

SWCNTs offer a strong candidate for next-generation marine coatings.

5. Electronics and Energy Storage

-

Consumer electronics and lithium-ion batteries face fire hazards due to overheating.

-

SWCNT-enhanced coatings can delay ignition and reduce flammability in devices.

Research Highlights and Case Studies

-

Academic Studies: Research has shown that adding as little as 1 wt% SWCNTs to polymer coatings significantly reduces peak heat release rate (PHRR) during combustion tests.

-

Hybrid Systems: Studies demonstrate strong synergy between SWCNTs and phosphorus-based retardants, where SWCNTs reinforce intumescent char layers.

-

Battery Applications: Experimental SWCNT coatings on lithium-ion battery casings delayed thermal runaway and reduced fire propagation.

Commercialization Challenges

Despite strong potential, commercialization of SWCNT fire-resistant coatings faces several hurdles:

-

High Production Cost

-

SWCNTs are more expensive to produce than graphene or multi-walled CNTs.

-

Cost reduction through large-scale production is still in progress.

-

-

Dispersion Difficulties

-

SWCNTs tend to bundle together due to Van der Waals forces.

-

Achieving uniform dispersion in coatings requires functionalization or surfactants.

-

-

Standardization and Testing

-

Lack of standardized flame-retardant testing protocols specific to SWCNTs.

-

Regulatory approval processes are lengthy.

-

-

Market Inertia

-

Industries are cautious about replacing well-established flame-retardant systems.

-

Adoption requires proven long-term stability and certification.

-

Future Outlook

SWCNTs are not expected to completely replace traditional flame retardants in the short term. Instead, the future lies in hybrid formulations:

-

SWCNTs + Intumescent Additives → Stronger and more stable char formation.

-

SWCNTs + Graphene → Enhanced thermal and barrier performance.

-

SWCNTs + Phosphorus/Clay Nanocomposites → Cost-effective, eco-friendly flame-retardant paints.

Over the next decade, SWCNT fire-resistant coatings may find early adoption in aerospace, EVs, and electronics, where performance justifies higher costs. As scalable production methods lower prices, broader adoption in construction and marine industries is expected.

Single-walled carbon nanotubes (SWCNTs) bring a unique combination of thermal stability, electrical conductivity, and mechanical reinforcement, making them promising candidates for next-generation fire-resistant coatings. They offer clear advantages over traditional flame retardants, including low loading requirements, lightweight protection, and eco-friendliness.

However, challenges such as high production costs, dispersion issues, and regulatory uncertainty must be addressed before widespread commercialization. The most realistic near-term path is hybrid coatings, where SWCNTs work alongside traditional retardants to enhance performance.

As industries move toward sustainable, non-toxic, and multifunctional fire-protection systems, SWCNTs are positioned to play a transformative role in the evolution of flame-retardant paints.