SWCNT vs. MWCNT: Conductive Mechanism and Performance Differences in Lithium Battery Applications

As the global lithium battery industry evolves toward higher energy density, faster charging, and improved safety, the role of carbon-based conductive additives becomes increasingly pivotal. Among these additives, single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) stand out as critical enablers of advanced battery performance.

While both forms of CNTs share a similar cylindrical nanostructure, their properties, conductive behavior, cost, and application scenarios differ substantially. This article provides a detailed comparison of SWCNTs and MWCNTs, with a special focus on their conductive mechanisms and implications for lithium battery manufacturers.

What Are SWCNTs and MWCNTs?

-

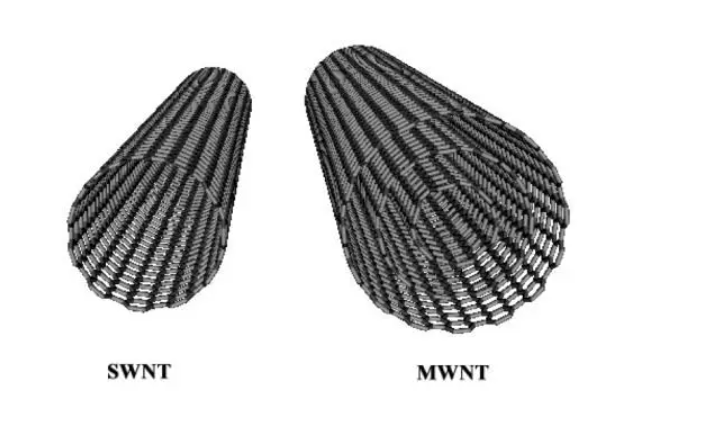

SWCNT (Single-Walled Carbon Nanotube): Composed of a single graphene sheet rolled into a tube with a typical diameter of 0.8–2 nm. Offers exceptional electrical, thermal, and mechanical properties.

-

MWCNT (Multi-Walled Carbon Nanotube): Consists of multiple concentric graphene cylinders (like a Russian nesting doll). Diameter ranges from 5–100 nm, depending on the synthesis method.

Though both fall under the category of CNTs, they function quite differently when dispersed in battery electrodes.

Conductive Mechanism in Lithium Batteries

Lithium battery electrodes (both cathode and anode) are composed of active materials (e.g., NMC, LFP, graphite), conductive additives, binders, and solvents. The goal of the conductive additive is to:

-

Establish an electron transport network through the electrode layer.

-

Maintain electrical contact between isolated or poorly conducting active material particles.

-

Enhance rate capability by reducing internal resistance.

Let’s now compare how SWCNTs and MWCNTs perform this function.

1. Electrical Conductivity

SWCNTs:

-

Exhibit ballistic electron transport due to their quasi-one-dimensional structure.

-

Intrinsic electrical conductivity can reach 10⁷ S/m, surpassing metals.

-

Even at low loadings (0.05–0.1 wt%), they form highly efficient networks.

MWCNTs:

-

Have lower intrinsic conductivity (10⁴–10⁵ S/m) due to more structural defects and interlayer resistance.

-

Require higher dosage (~0.2–0.5 wt%) to achieve similar conductivity effects.

-

Performance depends heavily on aspect ratio and defect density.

Conclusion: SWCNTs provide superior conductivity at lower dosage, which is critical for high-energy density cells where space is limited.

2. Percolation Network Formation

The ability of a conductive additive to form a percolation network—a continuous path for electrons—is key.

-

SWCNTs, with their ultrahigh aspect ratio (>1000) and flexibility, wrap around active particles, forming a robust 3D conductive web even at low concentrations.

-

MWCNTs also form networks but are stiffer, shorter, and more prone to agglomeration unless well-dispersed.

SWCNT Advantage:

-

Maintains contact during electrode swelling/shrinking cycles.

-

Ideal for fast-charging and high-silicon anode systems.

3. Impact on Battery Performance

a. Energy Density

-

SWCNTs allow for lower filler loading, maximizing the amount of active material in the electrode.

-

MWCNTs require higher loading, slightly reducing energy density.

b. Power Density

-

SWCNT-rich electrodes exhibit lower internal resistance and higher rate performance.

-

MWCNT-based systems can achieve good power, but require careful slurry formulation.

c. Cycle Life

-

SWCNTs improve mechanical integrity over cycles, especially in silicon-rich anodes.

-

MWCNTs perform well but may not match the flexibility and network resilience of SWCNTs.

4. Dispersibility and Processing

SWCNT Challenges:

-

More difficult to disperse uniformly due to strong van der Waals forces.

-

Require specialized surfactants or dispersants (e.g., XFZ20).

-

Sensitive to sonication and shear—can be damaged in processing.

MWCNT Advantages:

-

Easier to process in water or NMP-based systems.

-

More robust under high-shear mixing.

Industrial Note: Many manufacturers use MWCNT slurries for mass production but evaluate SWCNTs for performance-critical or premium cells.

5. Cost and Availability

SWCNTs:

-

Higher cost due to complex synthesis (e.g., CoMoCAT, HiPco).

-

Price range: ~$1000–10000/kg (industrial grade).

-

Lower global production capacity.

MWCNTs:

-

Economical at ~$30–500/kg for battery grade.

-

Available at scale from many Chinese producers.

Conclusion: MWCNTs dominate in cost-sensitive applications, while SWCNTs are reserved for premium markets like fast-charging EVs, aerospace cells, and silicon anodes.

6. Hybrid Systems: Combining Strengths

Many battery manufacturers now use hybrid conductive systems that blend:

-

MWCNT + Conductive Carbon Black: Cost-effective, stable performance.

-

SWCNT + Graphene or Carbon Black: High-performance, balanced cost.

-

MWCNT + SWCNT: Optimized network formation and cost-performance.

This allows for tunable conductivity, better dispersibility, and lower additive dosage.

Summary Table: SWCNT vs. MWCNT

| Property | SWCNT | MWCNT |

|---|---|---|

| Diameter | 0.8–2 nm | 5–100 nm |

| Conductivity (intrinsic) | ~10⁷ S/m | 10⁴–10⁵ S/m |

| Dosage in battery | 0.05–0.1 wt% | 0.2–0.5 wt% |

| Network Formation | Excellent (flexible, dense) | Good (stiff, prone to gaps) |

| Energy Density Impact | Minimal | Moderate (due to higher dosage) |

| Processing | Challenging | Easier |

| Cost | High | Moderate to Low |

| Applications | High-end, fast-charging, silicon anodes | Mass production, standard cells |

Conclusion

Choosing between SWCNT and MWCNT for lithium battery applications is a matter of performance, process, and price. While MWCNTs offer a cost-effective and scalable solution for standard cells, SWCNTs unlock performance for premium systems demanding ultra-high power, fast charging, or structural flexibility.

As battery chemistries evolve—especially with high-silicon anodes and solid-state technologies—SWCNTs may become indispensable, making it crucial for slurry and electrode developers to understand their behavior and optimize their usage.

Whether used alone or in combination, carbon nanotubes remain the invisible backbone of the next wave of lithium battery breakthroughs.