SWCNTs for High-Density Flexible Interconnects

Redefining Conductivity and Durability in Next-Generation Flexible Electronics

As electronics evolve toward thinner, lighter, and bendable designs, the demand for high-density flexible interconnects has grown dramatically. These interconnects—thin, conductive pathways that connect circuits and components in flexible displays, wearable devices, and foldable electronics—require materials that combine excellent conductivity, mechanical flexibility, and long-term reliability.

Traditional materials such as indium tin oxide (ITO), copper foils, or silver inks face serious challenges: cracking under bending, poor adhesion to flexible substrates, and limited patterning resolution.

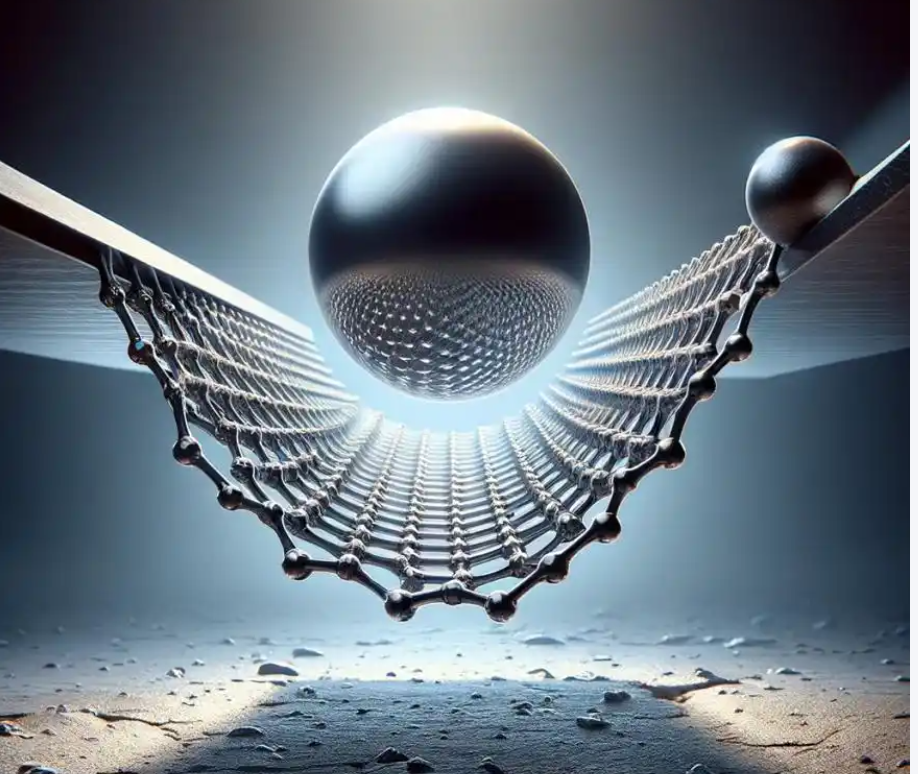

Enter Single-Walled Carbon Nanotubes (SWCNTs) — nanoscale carbon structures that offer metal-like conductivity, superb flexibility, and chemical stability. Their combination of high aspect ratio, quantum-level electron transport, and mechanical resilience makes SWCNTs ideal for flexible circuit interconnects where metals or brittle oxides fail.

Unique Properties of SWCNTs for Conductive Interconnects

Each SWCNT is a single graphene sheet rolled into a cylinder with diameters around 1–2 nm and lengths up to tens of micrometers. Their exceptional physical properties make them natural candidates for conductive pathways:

| Property | Typical Value | Function in Flexible Interconnects |

|---|---|---|

| Electrical Conductivity | ~10⁶–10⁷ S/m | Comparable to copper, enabling low-resistance signal transmission |

| Tensile Strength | >100 GPa | Maintains integrity under bending or stretching |

| Young’s Modulus | ~1 TPa | Provides flexibility without fatigue |

| Thermal Conductivity | 3000–6000 W/m·K | Prevents overheating in dense interconnects |

| Bending Radius | <1 mm | Ideal for wearable and foldable circuits |

(Data from Nano Letters, 2015; Carbon, 2019; ACS Applied Nano Materials, 2022)

Fabrication Approaches for SWCNT Interconnects

Several scalable fabrication strategies have been developed to pattern SWCNT films into dense, flexible circuit interconnects:

1. Spray-Coating and Inkjet Printing

-

SWCNT inks, stabilized with surfactants or polymers, can be directly printed onto PET, PI, or PDMS substrates.

-

Enables roll-to-roll manufacturing of large-area flexible circuits.

-

Achieves sheet resistances as low as 100–200 Ω/sq at 90% transparency.

2. Vacuum Filtration and Transfer Printing

-

Produces highly uniform SWCNT networks with controllable density and alignment.

-

Suitable for micro-patterned interconnect arrays in compact flexible devices.

3. Direct CVD Growth on Substrates

-

Grows aligned SWCNTs directly onto flexible polymer or metal foils.

-

Offers superior contact conductivity and long-term adhesion.

-

Used in stretchable transistors and sensor arrays.

Electrical and Mechanical Performance

When compared with conventional materials, SWCNT films exhibit remarkable electrical and mechanical balance:

| Material | Sheet Resistance (Ω/sq) | Bending Durability (Cycles at 5 mm radius) | Transparency |

|---|---|---|---|

| ITO | 30–60 | <100 | 85–90% |

| Silver Nanowires | 20–100 | ~1000 | 90% |

| SWCNT Film | 100–200 | >10,000 | 90–95% |

(Based on ACS Nano, 2017; Nano Energy, 2020; Advanced Functional Materials, 2022)

The key advantage is that SWCNT networks maintain conductivity after 10,000+ bending or stretching cycles, far exceeding ITO or metal-based interconnects.

This resilience comes from their percolation network — a web of overlapping nanotubes that continue conducting even when some junctions shift or separate during deformation.

Applications in Emerging Technologies

1. Flexible Displays and Foldable Devices

SWCNT interconnects serve as transparent, flexible conductive lines in OLED and micro-LED displays.

Their smooth film structure avoids cracking and maintains low resistance even when bent to tight radii — critical for foldable smartphones, tablets, and e-paper devices.

2. Wearable and Stretchable Electronics

SWCNT films printed on elastomers like PDMS or TPU create stretchable conductors that move naturally with the human body.

They can function as signal transmission lines, electrodes, and sensors in smart clothing, fitness bands, and medical patches.

3. High-Density Flexible PCBs

Replacing metal traces with SWCNT-based conductive networks allows ultra-thin circuit architectures without sacrificing reliability.

Such interconnects can reduce weight and thickness by over 50%, enabling integration into bio-implantable and soft robotics systems.

4. Transparent Electrode Networks for Touch Panels

SWCNT transparent electrodes can form the interconnect grid in touch sensors, combining optical transparency, low resistance, and mechanical flexibility—perfect for curved or foldable displays.

Thermal and Electromagnetic Advantages

SWCNTs not only conduct electricity efficiently but also exhibit excellent thermal and EMI (Electromagnetic Interference) performance:

-

Thermal Management: Their high thermal conductivity allows heat dissipation along the circuit plane, preventing hot spots in dense flexible electronics.

-

EMI Shielding: Networks of interconnected nanotubes can absorb and reflect electromagnetic waves, providing lightweight EMI protection for compact wearable devices.

Recent studies (Nano Energy, 2021) show SWCNT networks achieving 30–50 dB EMI shielding effectiveness at frequencies up to 10 GHz while maintaining flexibility — ideal for 5G and IoT circuits.

Integration with Other Materials

SWCNTs are often combined with other materials to enhance functionality:

-

SWCNT–Graphene Hybrids: Improve electrical percolation and mechanical strength simultaneously.

-

SWCNT–Polymer Composites: Enhance stretchability and adhesion to substrates.

-

SWCNT–Metal Nanoparticle Networks: Boost conductivity via hybrid charge transfer pathways.

These multifunctional composites expand the design window for smart flexible circuits capable of enduring repeated bending, twisting, and stretching without signal degradation.

Challenges and Future Prospects

Despite rapid progress, several challenges remain before SWCNT interconnects become mainstream in commercial products:

1. Uniformity and Purity

SWCNT synthesis often yields a mixture of metallic and semiconducting tubes. High-purity metallic SWCNTs (>95%) are required for low-resistance interconnects.

Current chirality-sorting techniques, such as density-gradient ultracentrifugation or selective chemistry, are improving but remain expensive.

2. Contact Resistance

At junctions and interfaces, tube-to-tube and tube-to-metal resistance can still limit overall conductivity. Engineering better contact materials (e.g., silver paste, graphene bridging) is a key research area.

3. Scalable Manufacturing

Ink-based printing and CVD growth methods must achieve uniformity at wafer scale for high-yield flexible circuit production.

Advances in roll-to-roll printing and aerosol jet deposition are paving the way for industrial-scale fabrication.

Theoretical Insights (Based on Open Research)

-

Quantum Conductivity: The ballistic electron transport length in metallic SWCNTs can reach up to 1 μm, minimizing scattering losses in nanoscale interconnects.

-

Percolation Threshold: For effective conductivity, a percolation network forms at ~0.1–0.3 wt% loading, much lower than other nanomaterials (graphene ~1 wt%).

-

Thermal Stability: SWCNT films maintain conductivity at temperatures up to 250–300 °C, suitable for flexible device encapsulation processes.

(Sources: Physical Review B, 2018; Nano Research, 2020; Carbon, 2023)

Single-Walled Carbon Nanotubes (SWCNTs) are emerging as the ultimate solution for high-density flexible interconnects in next-generation electronics. Their combination of metal-like conductivity, exceptional flexibility, and thermal and chemical stability positions them as a superior alternative to traditional metal or oxide conductors.

By enabling lightweight, durable, and transparent conductive pathways, SWCNTs can drive innovation in wearable devices, foldable displays, medical electronics, and smart textiles.

As scalable synthesis and printing technologies mature, SWCNT-based flexible interconnects are expected to play a central role in shaping the future of flexible, stretchable, and transparent electronics.