SWCNTs for High-Efficiency Thermoelectric Generators: Turning Waste Heat into Clean Energy

Every industrial process, vehicle engine, and electronic device produces one inevitable byproduct — waste heat. According to the International Energy Agency (IEA), over 60% of global energy is lost as heat during power generation, manufacturing, and transportation.

Thermoelectric generators (TEGs) offer a revolutionary way to convert this lost heat directly into electricity. However, their efficiency has long been limited by the performance of thermoelectric materials.

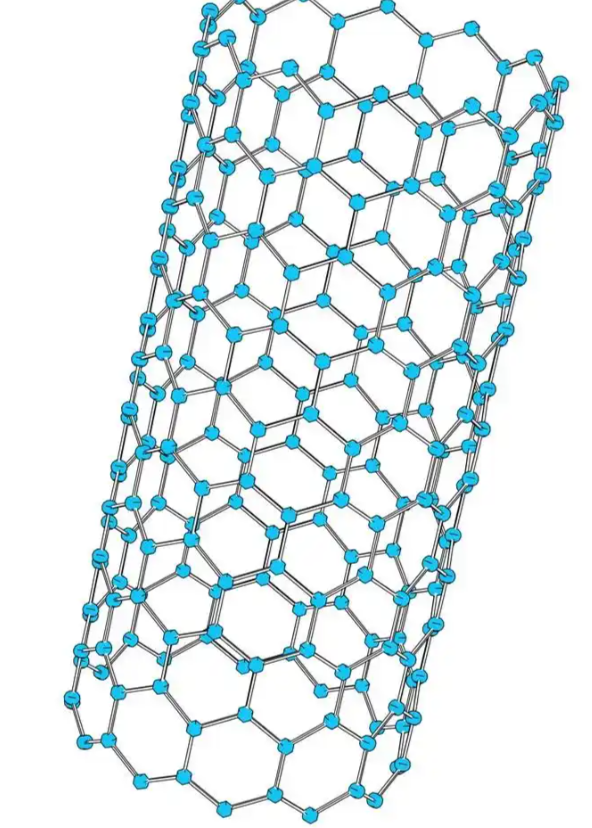

This is where Single-Walled Carbon Nanotubes (SWCNTs) come into play. With exceptional electrical conductivity, tunable band structure, and lightweight flexibility, SWCNTs are redefining what’s possible in high-efficiency, scalable thermoelectric systems.

What Are Thermoelectric Generators?

Thermoelectric generators (TEGs) work on the Seebeck effect — a phenomenon where a temperature difference across a material creates an electric voltage.

A TEG consists of two types of materials:

-

n-type (electron-dominant conductor)

-

p-type (hole-dominant conductor)

When heat flows from the hot side to the cold side, charge carriers move, generating electricity.

The performance of a thermoelectric material is determined by its figure of merit (ZT):

Where:

-

SS = Seebeck coefficient

-

σ\sigma = electrical conductivity

-

TT = temperature (K)

-

κ\kappa = thermal conductivity

A high ZT value requires a material that conducts electricity efficiently but blocks heat flow — a rare combination.

Why SWCNTs?

Single-Walled Carbon Nanotubes (SWCNTs) possess extraordinary properties that make them ideal candidates for advanced thermoelectrics:

-

Ultra-high electrical conductivity (10⁶–10⁷ S/m)

-

Low thermal conductivity when disordered

-

Lightweight and flexible

-

Bandgap tunability through doping and chirality control

-

Chemical stability and mechanical strength

These characteristics allow SWCNTs to enhance both the electrical and thermal performance of thermoelectric devices — improving efficiency while reducing weight and cost.

How SWCNTs Improve Thermoelectric Efficiency

1. Enhanced Electrical Conductivity

SWCNT networks form highly conductive pathways for charge carriers, increasing the Seebeck voltage and power factor (S2σS^2σ).

When aligned or doped, SWCNTs can surpass traditional materials like bismuth telluride in power density and flexibility.

2. Reduced Thermal Conductivity

In composite or disordered networks, SWCNT junctions scatter phonons (heat carriers), suppressing thermal conductivity (κκ) — which boosts the overall ZT value.

3. Doping and Bandgap Engineering

Through chemical doping (e.g., with nitric acid, gold chloride, or polymers), the Fermi level of SWCNTs can be precisely tuned to optimize p-type and n-type performance.

4. Hybrid Nanocomposites

SWCNTs are often blended with polymer matrices (PEDOT:PSS, PANI) or inorganic nanoparticles (Bi₂Te₃, SnSe), combining flexibility with high ZT performance.

Applications of SWCNT-Based Thermoelectrics

1. Waste Heat Recovery in Industry

Factories, refineries, and data centers release massive amounts of heat. SWCNT-based TEGs can capture and convert this energy into electricity, improving energy efficiency and lowering emissions.

2. Automotive and Aerospace Energy Harvesting

Vehicles and aircraft engines produce substantial heat. SWCNT TEGs can recover this energy for battery recharging, sensor power, or onboard electronics, reducing fuel consumption.

3. Wearable and Portable Power Sources

Flexible SWCNT thermoelectric films can harvest body heat to power wearable sensors, smart textiles, or medical monitors, enabling continuous self-powered operation.

4. Renewable Energy Systems

SWCNT TEGs integrated into solar panels or geothermal systems can convert unused heat into additional electricity — pushing renewable efficiency to new heights.

Case Studies and Experimental Progress

-

MIT and RIKEN Collaboration: Developed flexible SWCNT/polymer composites with ZT values exceeding 0.4, capable of powering small devices from body heat.

-

Korea Institute of Science and Technology (KIST): Created aligned SWCNT films showing up to three times higher Seebeck coefficients than random networks.

-

UC Berkeley Research Group: Demonstrated SWCNT–Bi₂Te₃ hybrid structures achieving up to 60% increase in energy conversion efficiency.

These findings confirm that SWCNTs are not just theoretical candidates but practical enablers for next-generation thermoelectrics.

Advantages Over Traditional Thermoelectric Materials

| Feature | Traditional Materials (Bi₂Te₃, PbTe) | SWCNT-Based Materials |

|---|---|---|

| Toxicity | Often toxic (tellurides, lead) | Non-toxic, carbon-based |

| Flexibility | Brittle | Highly flexible and lightweight |

| Temperature Range | Limited | Tunable for low- to mid-temperature |

| Sustainability | Rare elements | Abundant and eco-friendly |

| Manufacturing | Rigid bulk processing | Scalable printing and coating methods |

This makes SWCNT thermoelectrics particularly attractive for portable, wearable, and green energy applications.

Challenges and Research Directions

While the potential is undeniable, SWCNT-based TEGs still face several challenges:

-

Purity and Chirality Control – Metallic vs. semiconducting SWCNT ratios greatly affect performance; large-scale separation remains complex.

-

Interfacial Resistance – Junction resistance in networks limits carrier mobility; better alignment and bonding methods are needed.

-

Cost and Scalability – High-purity SWCNTs are still expensive, though prices are dropping with improved synthesis.

-

Thermal Stability – Long-term operation under fluctuating temperatures requires further optimization of dopants and encapsulation.

Future Outlook

The next generation of SWCNT thermoelectric materials will focus on:

-

Hybrid architectures combining SWCNTs with 2D materials like MoS₂ or graphene for enhanced ZT.

-

Printable thermoelectric inks for low-cost, flexible device fabrication.

-

Self-powered IoT and biomedical sensors harvesting ambient or body heat.

-

Integration with waste heat systems in factories, vehicles, and spacecraft for continuous energy recovery.

With advancements in chirality control, large-scale production, and hybrid design, SWCNTs are poised to play a pivotal role in turning waste heat into renewable electricity — a cornerstone of sustainable energy innovation.

Single-Walled Carbon Nanotubes (SWCNTs) are transforming the thermoelectric landscape by combining high electrical conductivity, tunable electronic properties, and lightweight flexibility.

From industrial heat recovery to wearable energy harvesting, SWCNT-based thermoelectric generators offer a path toward cleaner, more efficient, and decentralized power generation.

As materials science continues to push boundaries, SWCNTs stand at the forefront of energy harvesting and sustainable innovation — where every degree of wasted heat becomes a new source of clean power.