SWCNTs in High-Temperature Ceramics and Composites

Reinforcing the Future of Aerospace and Industrial Materials

Modern aerospace, defense, and industrial systems operate under extreme thermal and mechanical conditions.

Components such as turbine blades, heat shields, and armor panels must endure temperatures above 1000°C, rapid thermal cycling, and intense mechanical stress — all while maintaining low weight and long-term stability.

Ceramic materials (like SiC, Al₂O₃, and ZrO₂) are ideal for these applications due to their excellent hardness, corrosion resistance, and thermal stability.

However, ceramics are brittle by nature, prone to cracking and catastrophic failure under tensile or impact loads.

To overcome these inherent limitations, researchers are incorporating single-walled carbon nanotubes (SWCNTs) into ceramic matrices — creating a new generation of high-temperature ceramic composites that combine the best of both worlds:

-

Ceramics for thermal resistance and stiffness,

-

SWCNTs for strength, toughness, and electrical conductivity.

SWCNT-reinforced ceramics could redefine materials used in aerospace propulsion, hypersonic vehicles, and extreme industrial environments.

1. Why Use SWCNTs in Ceramics?

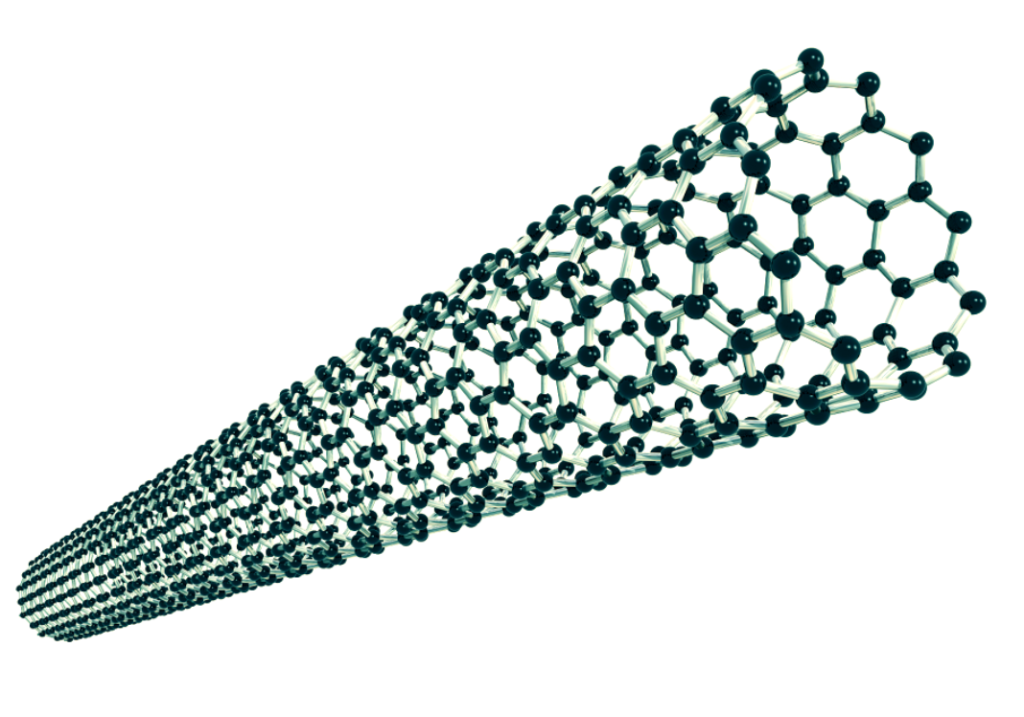

Single-walled carbon nanotubes are cylindrical carbon structures consisting of a single graphene sheet rolled into a tube, typically 1–2 nm in diameter and up to several micrometers long.

They possess extraordinary intrinsic properties:

| Property | Typical Value | Relevance for Ceramics |

|---|---|---|

| Tensile Strength | 50–150 GPa | Reinforces brittle matrices |

| Elastic Modulus | ~1 TPa | Enhances stiffness |

| Thermal Conductivity | >3000 W/m·K | Improves heat dissipation |

| Electrical Conductivity | ~10⁶ S/m | Enables ESD protection and sensing |

| Thermal Stability | >600°C (in air), >2800°C (inert) | Compatible with high-temperature processes |

These attributes make SWCNTs the ultimate reinforcing additive for ceramics used in harsh environments, improving their toughness, conductivity, and reliability.

2. Challenges of Conventional Ceramics

Traditional ceramics like silicon carbide (SiC), alumina (Al₂O₃), and zirconia (ZrO₂) suffer from:

-

Low fracture toughness (2–5 MPa·m½)

-

Poor resistance to thermal shock

-

Brittle fracture under mechanical load

As a result, even small surface defects can initiate cracks, leading to sudden failure.

This brittleness limits their use in dynamic or high-stress conditions such as turbine blades, aerospace skins, and defense armor.

The introduction of nanoscale reinforcements such as SWCNTs provides a route to toughen ceramics without sacrificing their thermal or chemical stability.

3. Reinforcement Mechanisms of SWCNTs

SWCNTs strengthen ceramic matrices through multiple synergistic mechanisms at the nanoscale:

A. Crack Bridging and Deflection

When cracks form in a ceramic matrix, embedded SWCNTs can bridge across crack surfaces, transferring load and preventing crack propagation.

Their flexibility allows crack deflection and energy absorption, dramatically improving fracture toughness.

B. Pull-Out and Debonding

Under stress, SWCNTs can partially debond and slide within the matrix, dissipating energy through frictional pull-out — similar to the fiber-toughening effect in composite laminates.

C. Load Transfer

Due to their high stiffness and interfacial bonding, SWCNTs carry part of the applied load, effectively redistributing stress away from brittle ceramic grains.

D. Thermal and Electrical Pathways

SWCNT networks enhance thermal conductivity, reducing temperature gradients and preventing thermal shock.

Additionally, they introduce electrical conductivity to otherwise insulating ceramics — beneficial for self-heating de-icing systems or structural health monitoring.

4. Processing of SWCNT–Ceramic Composites

Producing uniform composites requires overcoming two key challenges:

(1) Homogeneous dispersion of SWCNTs, and

(2) Strong interfacial bonding with the ceramic matrix.

A. Dispersion Techniques

SWCNTs naturally agglomerate due to van der Waals forces. To achieve even distribution, researchers use:

-

Ultrasonic dispersion in solvents;

-

Surfactant-assisted mixing;

-

Covalent or non-covalent functionalization of nanotube surfaces;

-

Sol–gel and colloidal blending for uniform particle suspension.

B. Fabrication Methods

Once dispersed, SWCNT–ceramic composites are typically fabricated using:

-

Hot pressing / Spark plasma sintering (SPS) — rapid consolidation that preserves SWCNT integrity;

-

Chemical vapor infiltration (CVI) — allows coating or infiltration of nanotubes into porous ceramics;

-

Freeze casting or extrusion — for directional alignment of CNT networks.

Among these, SPS has shown the best combination of density, bonding, and nanotube retention.

5. Performance Enhancement with SWCNTs

The inclusion of even small amounts of SWCNTs (0.5–2 wt%) can lead to remarkable improvements in both mechanical and functional properties.

A. Mechanical Properties

| Composite System | Fracture Toughness | Flexural Strength | Improvement |

|---|---|---|---|

| SiC + 1 wt% SWCNT | 6.5 MPa·m½ | 720 MPa | +60% toughness |

| Al₂O₃ + 0.5 wt% SWCNT | 5.1 MPa·m½ | 550 MPa | +45% strength |

| ZrO₂ + 1 wt% SWCNT | 7.3 MPa·m½ | 800 MPa | +70% toughness |

SWCNTs create a ductile reinforcement phase, significantly delaying catastrophic crack propagation.

B. Thermal and Electrical Conductivity

| Property | Pure Ceramic | SWCNT Composite | Gain |

|---|---|---|---|

| Thermal Conductivity (SiC) | 120 W/m·K | 200 W/m·K | +67% |

| Electrical Conductivity (Al₂O₃) | 10⁻¹² S/m | 10⁴ S/m | ~10¹⁶× increase |

This dual conductivity enables self-heating, thermal sensing, and EMI shielding, extending ceramics into multifunctional domains.

6. Applications in Extreme Environments

A. Aerospace and Aviation

-

Turbine blades and engine components: withstand >1300°C and thermal cycling;

-

Re-entry shields and hypersonic panels: improved ablation resistance and toughness;

-

Lightweight structural parts: reduced density and better damage tolerance.

SWCNT–SiC composites are already under investigation by NASA for next-gen propulsion systems.

B. Defense and Ballistics

-

Armor plates combining hardness and ductility for impact absorption;

-

Thermally stable radome materials with improved dielectric control.

SWCNTs also impart radar transparency with mechanical robustness, ideal for stealth applications.

C. Industrial and Energy Systems

-

High-temperature seals, bearings, and crucibles with increased lifespan;

-

Plasma-facing components in fusion reactors;

-

Thermal management coatings for heavy machinery.

These applications benefit from the durability, heat conduction, and crack resistance provided by SWCNT reinforcement.

7. Case Studies and Experimental Results

| Research Group / Institution | Composite Type | Key Findings | Year |

|---|---|---|---|

| Osaka University | Al₂O₃ + 1 wt% SWCNT | 2× fracture toughness; better thermal shock resistance | 2020 |

| Tsinghua University | SiC + SWCNT | 60% strength improvement, enhanced oxidation resistance | 2021 |

| University of Manchester | ZrO₂ + SWCNT | Improved ductility and conductivity | 2022 |

| NASA Ames | SWCNT–SiC matrix | Stable up to 1600°C, low weight for hypersonic panels | 2023 |

These studies confirm the scalable potential of SWCNT–ceramic composites for aerospace and industrial production.

8. Remaining Challenges

Despite the impressive progress, several challenges persist before widespread commercialization:

| Challenge | Description | Potential Solution |

|---|---|---|

| SWCNT agglomeration | Leads to non-uniform reinforcement | Improve dispersion and functionalization |

| Interface stability at high temperature | Weak bonding or reactions degrade performance | Use interfacial coatings (e.g., SiO₂, TiC) |

| Cost and scalability | High-purity SWCNTs remain expensive | Develop CVD mass production routes |

| Oxidation in air above 600°C | SWCNT degradation limits lifetime | Use protective ceramic coatings or inert atmospheres |

Ongoing R&D focuses on optimizing SWCNT dispersion, interfacial chemistry, and cost-effective fabrication to enable industrial-scale deployment.

9. The Future of SWCNT–Ceramic Composites

As synthesis and dispersion technologies mature, SWCNT–ceramic composites are expected to play a crucial role in:

-

Hypersonic and reusable spacecraft materials;

-

Advanced jet engine turbine blades;

-

Heat-resistant coatings for nuclear and fusion systems;

-

Smart high-temperature structures with integrated sensors.

In addition, their electrical conductivity opens new opportunities for embedded health monitoring and active temperature control — turning passive ceramics into intelligent structural materials.

Single-walled carbon nanotubes (SWCNTs) represent a transformative reinforcement for high-temperature ceramics, addressing long-standing challenges of brittleness and thermal shock sensitivity.

Through mechanisms like crack bridging, load transfer, and thermal conduction, SWCNT–ceramic composites achieve superior strength, ductility, and functionality at extreme conditions.

These materials are poised to revolutionize aerospace, defense, and industrial manufacturing, enabling lighter, stronger, and smarter systems capable of surviving the harshest environments.

SWCNT ceramics composites are not just the next step in materials engineering — they are the foundation of the next generation of high-temperature, intelligent, and resilient materials for a sustainable technological future.