SWCNTs in Lightweight Aerospace Structural Materials: Redefining the Future of Aviation and Spacecraft Design

In aerospace engineering, weight reduction and strength optimization are two fundamental goals. Every gram saved in an aircraft or spacecraft translates into improved fuel efficiency, greater payload capacity, and enhanced maneuverability. Traditionally, metals such as aluminum and titanium have dominated aerospace structures, but the search for stronger and lighter alternatives continues.

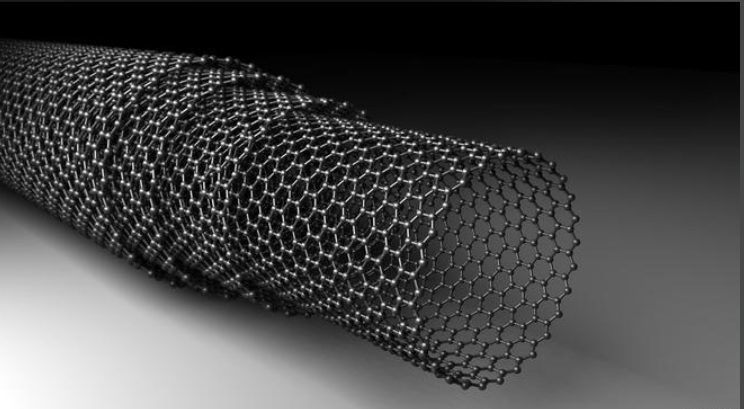

Enter Single-Walled Carbon Nanotubes (SWCNTs) — a material with extraordinary mechanical strength, thermal stability, and electrical conductivity, all packed into a nanoscale structure. These unique properties make SWCNTs a revolutionary additive for aerospace composite materials, promising the next generation of lightweight, durable, and multifunctional structures.

What Are SWCNTs?

Single-Walled Carbon Nanotubes (SWCNTs) are cylindrical carbon structures formed by rolling a single layer of graphene into a seamless tube. With diameters around 1 nanometer and lengths up to several micrometers, SWCNTs possess one of the highest strength-to-weight ratios known to science.

Key Properties of SWCNTs:

-

Tensile Strength: Up to 100 times stronger than steel.

-

Elastic Modulus: Exceeds 1 TPa, offering extreme stiffness.

-

Density: About one-sixth that of steel.

-

Thermal Conductivity: >3000 W/m·K — ideal for high-temperature aerospace environments.

-

Electrical Conductivity: Comparable to copper but at a fraction of the weight.

These characteristics make SWCNTs one of the most promising nanomaterials for advanced aerospace composites.

Why Aerospace Needs SWCNT-Reinforced Materials

Modern aerospace systems face multiple challenges:

-

The need for ultra-lightweight yet strong materials.

-

Thermal and mechanical stability at extreme temperatures.

-

Resistance to fatigue, impact, and radiation in harsh environments.

SWCNTs, when integrated into polymers, metals, or ceramics, can dramatically improve the mechanical strength, stiffness, and heat resistance of composite materials — all without adding significant weight.

How SWCNTs Enhance Aerospace Composite Materials

1. Mechanical Reinforcement

Even small additions (0.1–2 wt%) of SWCNTs can significantly improve tensile strength and Young’s modulus of epoxy and polymer matrices.

-

The high aspect ratio and strong interfacial bonding of SWCNTs create a reinforcing network, distributing stress more evenly across the composite.

-

Enhanced crack resistance and fatigue life make components more reliable under dynamic loads.

2. Thermal Stability and Heat Dissipation

SWCNTs’ exceptional thermal conductivity helps dissipate heat efficiently, preventing structural degradation in high-speed aircraft, jet engines, and spacecraft.

-

Used in thermal shielding, satellite panels, and propulsion systems.

3. Electromagnetic Shielding and Conductivity

SWCNT-reinforced composites offer lightweight EMI shielding, replacing heavy metallic layers.

-

Ideal for satellite housings and avionics enclosures that require signal protection.

4. Damage Sensing and Smart Structures

Due to their conductive network, SWCNT composites can function as self-sensing materials, detecting strain, cracks, or impact damage in real time — a critical advantage in aerospace maintenance and safety.

Applications in Aerospace and Aviation

1. Aircraft Structural Components

-

SWCNTs are incorporated into fuselage panels, wings, and control surfaces to reduce weight while maintaining rigidity.

-

Provide resistance against fatigue and environmental degradation.

2. Satellites and Spacecraft

-

In spacecraft, every gram counts. SWCNT composites are used in structural panels, antennas, and thermal protection systems.

-

Offer superior radiation shielding and thermal control for long-duration missions.

3. Unmanned Aerial Vehicles (UAVs)

-

SWCNT-reinforced polymers make UAVs lighter, faster, and more energy-efficient, extending flight duration.

4. Propulsion and Thermal Systems

-

SWCNT composites can withstand high temperatures and mechanical stress, ideal for turbine blades, engine housings, and exhaust systems.

Case Studies and Research Highlights

-

NASA and Boeing have investigated SWCNT-infused polymers for structural and EMI shielding applications, reporting up to 30–40% weight reduction over aluminum.

-

MIT researchers developed a SWCNT-reinforced epoxy composite achieving twofold improvement in strength-to-weight ratio.

-

European Space Agency (ESA) studies suggest SWCNT composites could reduce satellite mass by up to 20% without compromising performance.

Manufacturing and Processing Advances

1. Dispersion Techniques

Achieving uniform SWCNT dispersion remains critical. Advances in ultrasonication, surfactant-assisted processing, and functionalization ensure better bonding with matrix materials.

2. Functionalization for Compatibility

Chemical modification of SWCNT surfaces enhances adhesion to polymers and metals, preventing agglomeration and improving stress transfer.

3. Additive Manufacturing Integration

SWCNT-enhanced filaments are now being used in 3D printing lightweight aerospace components, enabling on-demand production and design flexibility.

Challenges in Aerospace Adoption

Despite their immense potential, several challenges must be addressed before SWCNTs see full-scale adoption in aerospace manufacturing:

-

Cost and Scalability — Producing high-purity SWCNTs in large quantities remains expensive.

-

Dispersion and Alignment — Achieving uniform alignment in composites is critical for maximizing performance.

-

Processing Compatibility — Integration with traditional aerospace manufacturing processes (like resin transfer molding) requires optimization.

-

Certification and Standardization — Aerospace materials demand rigorous testing and long-term validation before commercial deployment.

The Future of SWCNT Aerospace Composites

The roadmap for SWCNT-reinforced materials is rapidly evolving, with promising directions including:

-

Hybrid Carbon Nanomaterials — Combining SWCNTs with graphene or carbon fibers for synergistic performance.

-

Smart Aerospace Structures — Embedding SWCNTs for real-time structural health monitoring.

-

Eco-Friendly Manufacturing — Developing sustainable SWCNT synthesis and composite processing methods.

-

Next-Generation Aircraft and Satellites — Leveraging SWCNTs to achieve lighter, stronger, and more energy-efficient vehicles.

As aerospace engineers continue to push boundaries, SWCNTs are set to play a defining role in lightweight material innovation, paving the way for safer, faster, and more sustainable air and space travel.

Single-Walled Carbon Nanotubes (SWCNTs) represent a paradigm shift in aerospace material science. Their extraordinary mechanical strength, thermal conductivity, and low density make them an ideal additive for lightweight composite structures used in aircraft, satellites, and drones.

While challenges in cost, processing, and certification remain, ongoing advances in nanocomposite engineering are rapidly overcoming these barriers.

The result is clear: the future of aerospace materials lies not in heavier metals, but in nanostructured carbon. With SWCNTs leading the charge, the next generation of aerospace systems will soar higher, faster, and farther — all while being lighter and more efficient than ever before.