SWCNTs in Next-Generation Lithium-Sulfur Batteries: Unlocking the Future of High-Energy Energy Storage

As the demand for high-energy-density, lightweight, and sustainable batteries continues to grow — especially for electric vehicles (EVs), drones, and renewable energy systems — traditional lithium-ion batteries are approaching their theoretical performance limits.

To move beyond this plateau, researchers have turned their attention to lithium-sulfur (Li–S) batteries, which promise 5–10 times higher theoretical energy density (2,600 Wh/kg) and use abundant, low-cost sulfur as a cathode material.

However, Li–S batteries face one major challenge: the “polysulfide shuttle effect.” This phenomenon leads to rapid capacity fading and poor cycle stability.

Here, Single-Walled Carbon Nanotubes (SWCNTs) have emerged as a game-changing nanomaterial — capable of suppressing polysulfide migration, improving conductivity, and stabilizing the overall electrochemical process.

The Promise and Challenge of Lithium-Sulfur Batteries

⚡ The Advantages

Lithium-sulfur batteries are considered one of the most promising “next-generation” energy storage systems due to:

-

Ultra-high theoretical energy density (2600 Wh/kg)

-

Abundant and low-cost sulfur resources

-

Environmental friendliness (no heavy metals like cobalt)

-

Potential for lightweight and flexible battery designs

⚠️ The Challenges

Despite these benefits, Li–S batteries suffer from several key problems:

-

Polysulfide Shuttle Effect

During discharge, sulfur (S₈) converts to lithium polysulfides (Li₂Sₙ, n=4–8), which dissolve in the electrolyte and migrate to the anode. This causes loss of active material, self-discharge, and capacity decay. -

Poor Conductivity

Both sulfur and lithium sulfide (Li₂S) are electrically insulating, resulting in sluggish redox kinetics and low utilization. -

Volume Expansion

The sulfur cathode undergoes a ~80% volume change during cycling, leading to structural degradation. -

Short Cycle Life

The combined effects of shuttle, poor conductivity, and mechanical stress limit the battery to fewer than 100 cycles in conventional designs.

How SWCNTs Solve the Polysulfide Problem

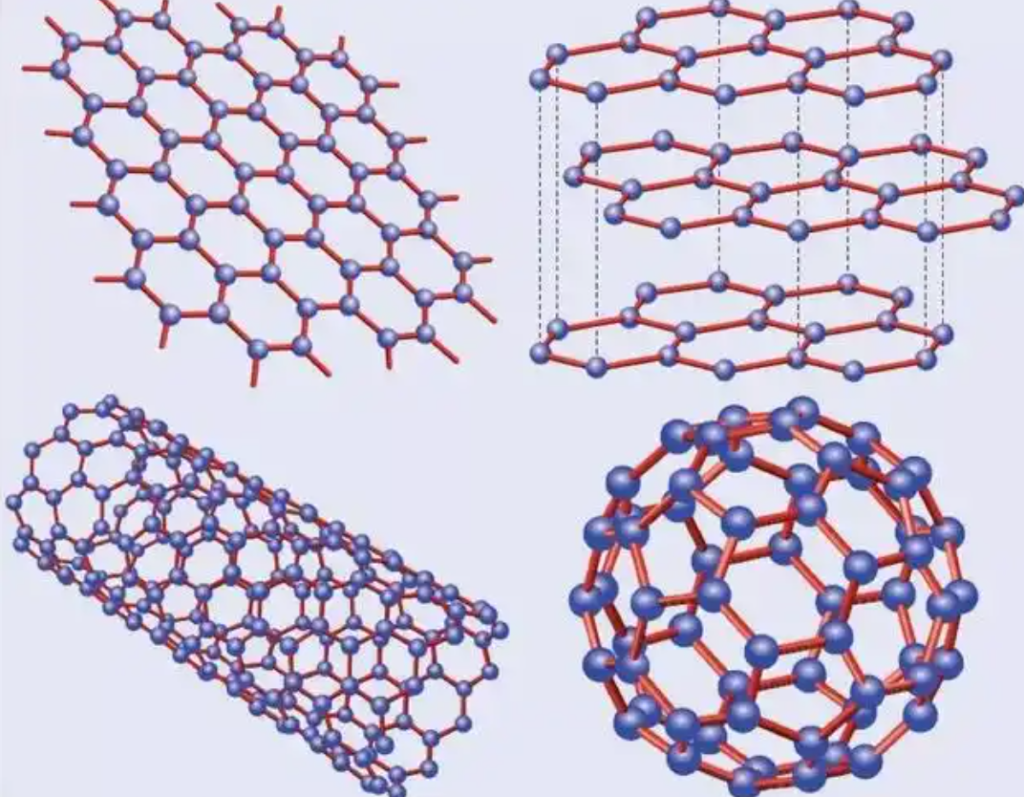

Single-Walled Carbon Nanotubes (SWCNTs) offer a unique combination of electrical conductivity, mechanical flexibility, and nanoscale porosity that directly address these issues.

1. Conductive Network for Fast Electron Transport

SWCNTs create a continuous, highly conductive matrix throughout the sulfur cathode, ensuring efficient electron transport — even as sulfur converts between solid and liquid states.

-

Improves active material utilization

-

Accelerates redox reactions

-

Reduces internal resistance and polarization

2. Polysulfide Adsorption and Trapping

SWCNTs have large surface areas and can be functionalized (with oxygen or nitrogen groups) to chemically anchor polysulfides, reducing their diffusion into the electrolyte.

This suppresses the shuttle effect, stabilizing the sulfur cathode and prolonging cycle life.

3. Physical Barrier Formation

The interconnected nanotube network acts as a mechanical and electrochemical barrier, physically blocking polysulfide migration while allowing lithium-ion transport.

4. Structural Buffering and Mechanical Stability

SWCNTs’ flexibility accommodates sulfur’s volume expansion and contraction during cycling, preventing cathode cracking or pulverization.

Advantages of SWCNT-Integrated Li–S Batteries

| Property | Conventional Li–S | SWCNT-Enhanced Li–S |

|---|---|---|

| Conductivity | Poor | Excellent (10⁶ S/m) |

| Polysulfide Control | Weak | Strong adsorption + barrier |

| Cycle Life | <100 cycles | >1000 cycles demonstrated |

| Coulombic Efficiency | <80% | >98% |

| Mechanical Stability | Low | High (flexible matrix) |

These improvements make SWCNT-based Li–S systems a viable replacement for Li-ion batteries in high-performance applications.

Key Mechanisms at Work

1. SWCNT–Sulfur Composite Cathodes

By mixing sulfur particles with SWCNTs, researchers form uniform hybrid structures where sulfur is tightly wrapped in a conductive nanotube matrix.

-

This improves sulfur utilization up to 90%.

-

Cycle life extends beyond 500–1000 cycles with minimal capacity fade.

2. SWCNT-Modified Separators

Applying an SWCNT coating to the battery separator creates a selective barrier that intercepts migrating polysulfides while maintaining ionic conductivity.

This approach reduces shuttle effects and self-discharge.

3. SWCNT Conductive Interlayers

An additional SWCNT layer between the cathode and separator can trap diffused polysulfides and reconvert them into active sulfur species — effectively recycling lost capacity.

Research Highlights

-

Stanford University: Developed an SWCNT-sulfur cathode achieving 1200 mAh/g capacity after 500 cycles with 99% Coulombic efficiency.

-

MIT: Demonstrated an SWCNT-modified separator that reduced polysulfide crossover by 85%, maintaining stable operation for over 700 cycles.

-

Chinese Academy of Sciences: Produced flexible SWCNT/Li–S electrodes with areal capacity of 10 mAh/cm², paving the way for high-energy wearable batteries.

Applications and Industry Impact

1. Electric Vehicles (EVs)

SWCNT-enhanced Li–S batteries can double driving range while cutting weight by up to 30%. Their lower cost and environmental benefits make them ideal for next-generation EV platforms.

2. Aerospace and Drones

The high energy-to-weight ratio of SWCNT–Li–S systems enables longer flight times and higher payload capacities.

3. Grid-Scale Energy Storage

Combining low-cost sulfur with high performance makes SWCNT–Li–S batteries attractive for renewable energy storage, supporting solar and wind integration.

4. Portable and Wearable Electronics

SWCNT films’ flexibility allows Li–S batteries to power bendable or wearable devices, including smart clothing and flexible displays.

Challenges and Future Research

While promising, several barriers remain before SWCNT–Li–S batteries become commercially dominant:

-

SWCNT Production Cost – High-purity SWCNTs are still expensive; scalable synthesis methods like floating catalyst CVD are improving affordability.

-

Uniform Dispersion – Achieving homogeneous mixing of SWCNTs with sulfur requires advanced processing techniques.

-

Electrolyte Optimization – The compatibility between SWCNTs and new solid or quasi-solid electrolytes must be optimized.

-

Safety and Stability – Ensuring long-term thermal and chemical stability under real-world conditions remains a focus.

Future work aims to integrate SWCNTs with graphene frameworks, solid-state electrolytes, and AI-optimized architectures for commercial-scale Li–S batteries.

The Road to Commercialization

The pathway to market readiness involves:

-

Hybrid composite scaling – producing SWCNT–sulfur composites via roll-to-roll coating or 3D printing.

-

Cost reduction – leveraging mass-production advances from EV and nanocarbon industries.

-

Industry partnerships – companies like Oxis Energy, LG Chem, and Sion Power are exploring SWCNT integration for prototype cells.

-

Sustainability – SWCNT–Li–S batteries rely on sulfur (a waste byproduct) and carbon nanotubes (low environmental impact), aligning with circular economy goals.

By enhancing electrical conductivity, suppressing sulfur migration, and improving mechanical integrity, SWCNTs unlock the full potential of Li–S technology — achieving higher capacity, longer lifespan, and greater efficiency.

From electric vehicles to aerospace systems, SWCNT-enhanced Li–S batteries represent a major leap toward lightweight, sustainable, and high-energy power solutions for the next generation of clean technology.