R&D → Lab → Pilot → Industrial scale support available.

GrapheneRich provides graphene, CNT and conductive material solutions with pilot-line support for battery, thermal and coating applications.

From Materials Incubation to Application Integration

We focus on graphene thermal interface and heat dissipation materials, backed by a full incubation service — enabling rapid transition from lab-scale to industrial-scale.

Our integrated offering includes:

- Graphene materials incubation (formulation, prototyping, performance tuning)

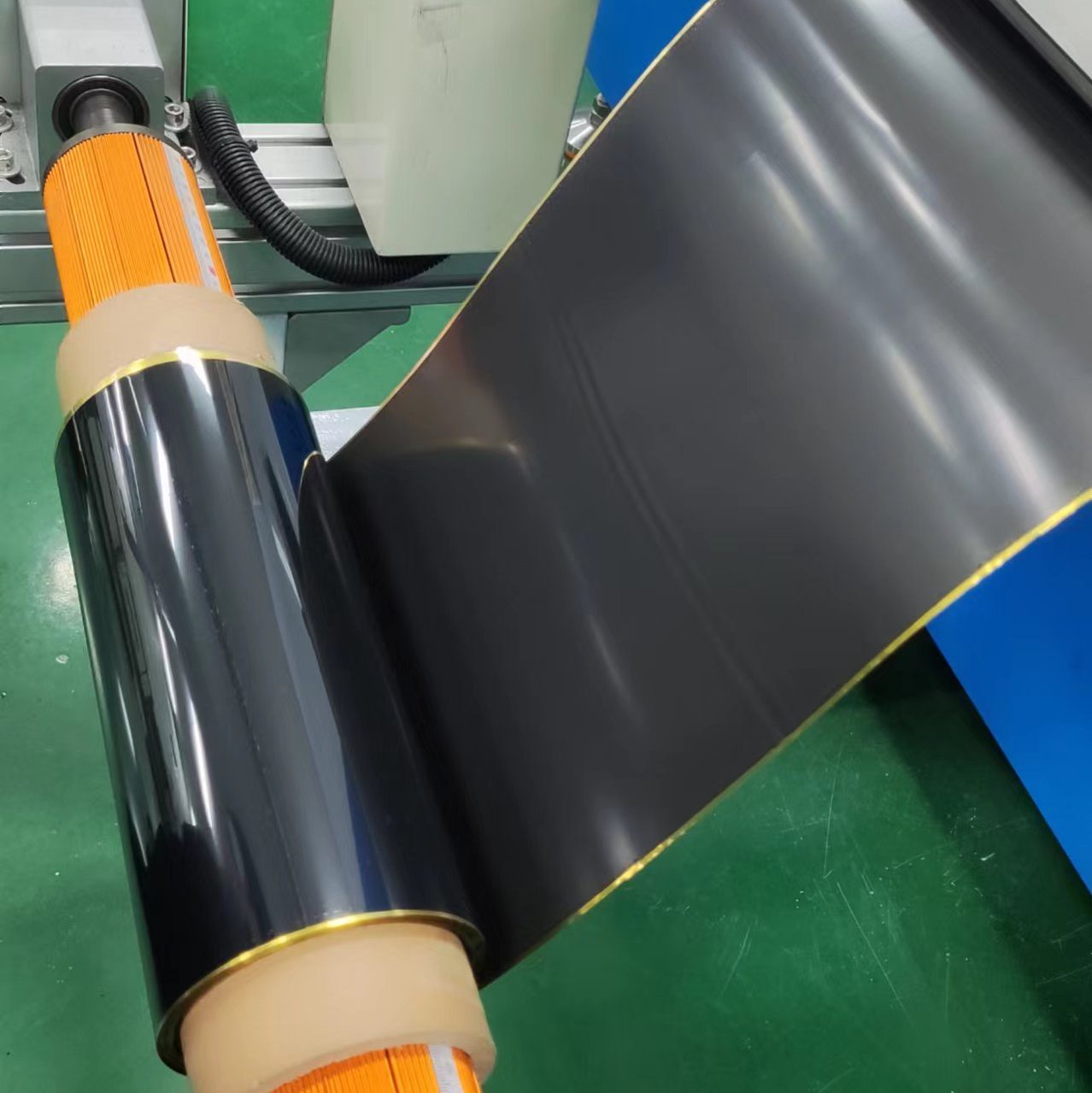

- Custom material engineering (powder, paste, film, and composite options)

- System-level thermal integration and product design

- Mass production support with traceable quality control

We do not just provide materials —

we accelerate graphene adoption in real products.

Key Advantages

End-to-End Incubation Capability

Accelerate material adoption from concept to production.

Ultra-High Thermal Conductivity

Superior heat dissipation unlocks better performance and stability.

Ultra-Thin & Lightweight

Enable compact design with lower weight vs. metal solutions.

Customizable & Form-Flexible

Adaptable to flat/curved surfaces and special shapes.

Industrial-Grade Reliability

Consistent performance across harsh thermal cycles.

Application Scenarios

From incubation stage to commercial deployment:

- Electronics Cooling

High-power LED, 5G base stations, servers - EV & Energy Storage Thermal Management

Battery pack and module cooling (>50kWh systems) - Power Electronics

Inverters, power modules, communication equipment - Consumer & Wearable Devices

Ultra-thin products requiring discreet thermal solutions

Typical performance benefits:

Temperature reduction 10–20% • Structural thickness reduced up to 50% • Longer device lifespan

Graphene Adoption Barriers

Long and uncertain path from lab innovation to mass productionPerformance gap between raw graphene materials and real thermal solutions

Lack of mature incubation and engineering support for rapid commercialization

Thermal Challenges Are Growing

Higher power density → excessive heat and reduced device lifetime

Limited space for traditional cooling components

Reliability risks under demanding operating conditions

— High surface area and superior conductivity for coatings, batteries, and composites.

— Strong, conductive, and scalable for energy and electronic systems.

Carbon Quantum Dots

— Luminescent nanocarbons for bioimaging, sensing, and optoelectronics.

Conductive Carbon & Carbon Black

— Reliable conductive fillers and additives for inks, plastics, and electrodes.

Hybrid & Composite Carbon Materials

— Engineered blends for multifunctional performance.

Advanced Carbon Structure

— Aerogels, foams, and films for cutting-edge applications.

– Li-ion, solid-state, and sodium-ion batteries, supercapacitors, and fuel cells.

– Flexible electronics, conductive inks, EMI shielding, and sensors.

Coating & Protection

– Corrosion resistance, thermal coatings, and high-performance surface protection.

Composites & Structural Materials

– Lightweight reinforcement and conductive composites.

Thermal Management & Insulation

– Heat dissipation, insulation, and fire protection systems.

What Our Customers Say?

🗣️Real feedback from customers demonstrates our commitment to quality and service. We continuously collect testimonials, product reviews, and satisfaction surveys to ensure our solutions meet your needs.

I🔍Identify the best graphite and graphene products for your business. Compare specifications, costs, and brand reputations to build a shortlist that matches your technical and budget requirements.

🧪Source reliable suppliers, test product samples with your design, and confirm performance before full-scale production.

🌐We provide end-to-end graphene solutions, collaborating with partners across advanced materials, electronics, and OEM industries — all compliant with ISO and RoHS standards.

🚚Finalize purchases smoothly with GrapheneRich. We handle contract processing, production, and timely delivery — ensuring you receive materials when you need them.