The Future of High-Performance Lithium-Ion Batteries: Prospects for Single-Walled Carbon Nanotube and Graphene Composites

The demand for high-performance lithium-ion batteries (LIBs) is intensifying as industries push the boundaries of energy storage for electric vehicles (EVs), renewable energy systems, and portable electronics. However, achieving greater energy density, faster charge-discharge rates, and enhanced safety remains a technical challenge. In response, advanced carbon nanomaterials—particularly single-walled carbon nanotubes (SWCNTs) and graphene—are emerging as game-changing components in LIB development.

This article explores the complementary advantages of SWCNTs and graphene, their synergies in composite materials, and their transformative potential in enabling next-generation LIBs.

1. Challenges in Lithium-Ion Battery Performance

1.1 Energy Density Limits

Conventional graphite anodes, while reliable and cost-effective, have a theoretical capacity of only 372 mAh/g, limiting LIB energy density. Meeting the demands for EVs and other applications requires materials with higher capacity.

1.2 Slow Charge-Discharge Rates

The rate capability of LIBs is constrained by ionic and electronic transport limitations in traditional electrode materials. Slow ion diffusion in the electrode matrix can lead to inefficiencies during high-current operations.

1.3 Mechanical Degradation

Repetitive lithiation and delithiation cycles cause volume expansion and structural degradation in LIB electrodes, leading to capacity fading and reduced cycle life.

1.4 Thermal and Safety Concerns

Thermal runaway, a major risk in LIBs, is exacerbated by inefficient heat dissipation and internal short circuits caused by dendrite growth or material degradation.

2. Single-Walled Carbon Nanotubes: A Game-Changing Material

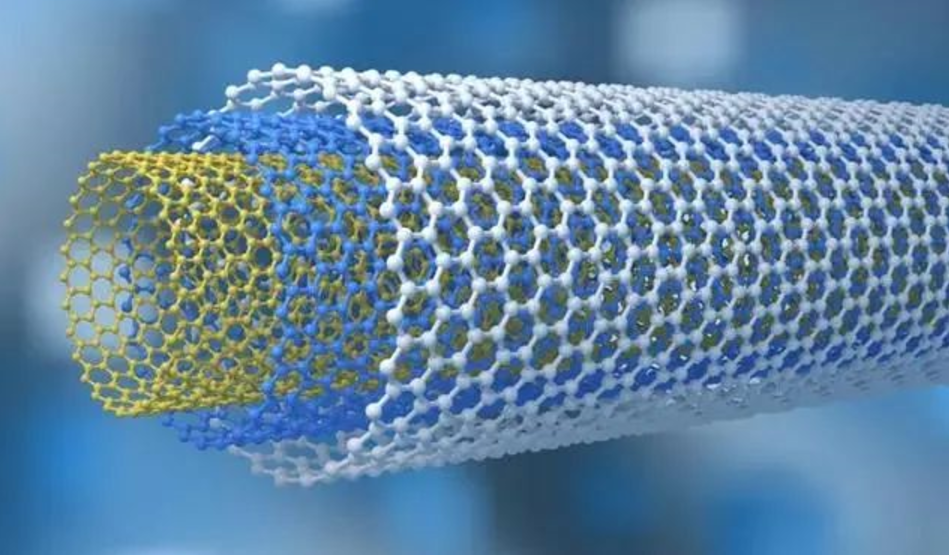

SWCNTs, with their unique one-dimensional structure, exhibit exceptional electrical conductivity, mechanical strength, and thermal stability, making them ideal candidates for LIB enhancement.

2.1 Superior Conductivity

- SWCNTs have a conductivity of approximately 10410^4104–10510^5105 S/cm, significantly higher than conventional carbon additives.

- As conductive networks in LIB electrodes, they reduce resistance and enable faster charge-discharge rates.

Example:

Studies have demonstrated that adding just 1%–2% SWCNTs to LIB cathodes improves electrical conductivity by up to 70%, significantly enhancing rate performance.

2.2 Mechanical Reinforcement

- SWCNTs have a tensile strength of over 100 GPa, providing structural support to mitigate electrode cracking during cycling.

- Their flexibility allows them to accommodate the volume changes of active materials like silicon or lithium metal.

2.3 Challenges in SWCNT Utilization

- Dispersion: Achieving uniform dispersion of SWCNTs within electrodes remains a technical challenge due to their tendency to aggregate.

- Cost: High production costs hinder their widespread adoption, though recent advances in chemical vapor deposition (CVD) are reducing these barriers.

3. Graphene: The Two-Dimensional Wonder Material

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers unparalleled properties that address LIB performance bottlenecks.

3.1 High Surface Area and Capacity

- Graphene’s theoretical surface area of 2630 m²/g provides abundant active sites for lithium-ion adsorption, enhancing specific capacity.

- Reduced graphene oxide (rGO) has been shown to achieve capacities of up to 540 mAh/g when used as an anode material.

3.2 Ionic and Electronic Transport

- Graphene’s high electronic conductivity (10610^6106 S/m) accelerates charge transfer, while its two-dimensional structure facilitates rapid ion diffusion.

- In composite electrodes, graphene acts as a conductive scaffold, reducing ionic resistance and enabling uniform lithium deposition.

3.3 Thermal Management

- Graphene’s thermal conductivity of 3000–5000 W/m·K efficiently dissipates heat, reducing the risk of thermal runaway.

Example:

Tesla’s incorporation of graphene-enhanced electrodes in experimental LIBs has shown improved thermal stability and cycle life, particularly for high-performance EV applications.

Challenges in Graphene Integration

- Scalable production of high-quality graphene remains challenging. Techniques like liquid-phase exfoliation and CVD are being optimized to address this.

- Restacking of graphene sheets can reduce its effective surface area, necessitating structural modifications.

4. Synergies of SWCNT-Graphene Composites

Combining SWCNTs and graphene in composite materials amplifies their individual strengths, offering a powerful solution to LIB performance challenges.

4.1 Conductive and Mechanical Networks

SWCNTs form one-dimensional conductive pathways, while graphene provides a two-dimensional scaffold, resulting in a three-dimensional conductive network. This structure:

- Enhances electron transport and charge uniformity.

- Mitigates mechanical degradation by distributing stress across the composite.

4.2 Boosting Energy Density

Graphene’s high capacity complements SWCNTs’ conductive properties, enabling higher active material utilization.

Example:

Researchers at MIT developed SWCNT-graphene hybrid anodes that achieved capacities of 600 mAh/g—60% higher than conventional graphite—while maintaining excellent rate performance.

4.3 Improved Cycling Stability

The composite’s flexibility accommodates volume changes in high-capacity materials like silicon, extending battery cycle life.

Example:

A team in South Korea demonstrated that SWCNT-graphene composites in silicon anodes reduced capacity fade by 30% after 500 cycles.

5. Real-World Applications and Case Studies

5.1 Electric Vehicles (EVs)

SWCNT-graphene composites are being tested in high-energy-density LIBs for EVs. By enabling faster charging and longer range, these batteries address critical adoption barriers.

Example:

Toyota is exploring graphene-SWCNT-enhanced batteries for next-generation EVs, targeting a 50% increase in energy density.

5.2 Consumer Electronics

For smartphones and laptops, the lightweight and high-capacity characteristics of these composites offer extended battery life without increasing size.

Example:

Samsung integrated graphene composites into experimental LIBs, achieving 30% faster charging times.

5.3 Renewable Energy Storage

In grid-scale storage, the durability and conductivity of SWCNT-graphene composites ensure stable performance under high-current cycling.

6. Overcoming Barriers to Commercialization

Despite their advantages, challenges remain:

- Cost Reduction: Scaling up the production of SWCNTs and graphene through methods like plasma-enhanced CVD and green exfoliation.

- Material Uniformity: Addressing dispersion and integration issues with advanced surfactants and processing techniques.

- Standardization: Developing industry standards for composite materials to streamline adoption in LIB manufacturing.

Conclusion

Single-walled carbon nanotubes and graphene composites represent the future of high-performance lithium-ion batteries, combining unmatched conductivity, mechanical strength, and thermal stability. By overcoming challenges such as cost and scalability, these materials will enable breakthroughs in energy density, fast charging, and safety, meeting the demands of EVs, consumer electronics, and renewable energy systems. As research advances and commercialization accelerates, the transformative potential of SWCNT-graphene composites will drive the next chapter of the energy revolution.