Introduction: Graphene—The “Wonder Material of the Future”

Graphene, hailed as the “wonder material of the future,” has captivated both the scientific and industrial communities since its successful isolation in 2004. As the thinnest, strongest, and most conductive two-dimensional material known, graphene offers unprecedented potential across various technological fields. From electronic devices and energy storage to aerospace and medical applications, graphene has opened new avenues for breakthroughs in traditional material technologies. Its unique properties have not only fascinated researchers but also sparked waves of innovation from fundamental scientific research to large-scale commercialization.

II. The Origin and Applications of Graphite: The Predecessor of Graphene

1. Structure and Evolution of Graphite

Graphite is a typical carbon-based material, and its unique crystalline structure determines its physical and chemical properties. It consists of multiple layers of carbon atoms arranged in a hexagonal lattice, with each layer being a two-dimensional, single-atom-thick sheet. These layers are held together by weak van der Waals forces, giving graphite its excellent conductivity and lubricating properties. This weak interlayer interaction allows scientists to peel off thin layers of graphite, ultimately isolating a single atomic layer known as graphene.

Graphite is widely found on Earth in the form of ore deposits. Countries such as China, India, and Brazil are among the world’s leading producers of natural graphite. Graphite commonly forms within metamorphic rocks or volcanic environments through geological processes that span millions of years. Due to its layered structure and chemical stability, graphite has played a significant role in human civilization throughout history.

Often referred to as an “ancient material,” graphite has been used since ancient times to produce ink for writing and painting. During the European Renaissance, graphite became popular as a pencil core due to its ease of use, contributing to the advancement of written communication and knowledge dissemination. Graphite’s role extends beyond cultural relevance to serve as a key foundational material in modern industry.

2. Traditional Functions and Applications of Graphite

Graphite’s physical and chemical properties enable its use in both everyday life and industrial sectors. Thanks to its soft, layered structure, it excels in various applications:

- Everyday Applications

- Pencil Cores: Graphite mixed with clay is fired to create pencil cores, which are known for their easy writing and erasability.

- Lubricants: The layered structure of graphite reduces friction, making it ideal for use in machinery, particularly in high-temperature or humid environments.

- Refractory Materials: Due to its high-temperature resistance, graphite is widely used in furnace linings within the metallurgy industry.

- Industrial Applications

- Electrode Materials: Graphite electrodes are essential in electrolysis and metallurgical processes, especially in the production of aluminum and steel.

- Corrosion-Resistant Materials: Thanks to its chemical stability, graphite is used to manufacture corrosion-resistant equipment and pipelines for the chemical industry.

- Metallurgical Additives: In steelmaking, graphite powder serves as a deoxidizer and carburizing agent to enhance the quality of steel.

Despite graphite’s versatility, its limitations as a material have become increasingly apparent. Since it consists of multiple layers, its thickness constrains the performance of certain electronic components and conductive materials. In some industries, the need for more efficient and flexible materials has driven further research into graphite.

Graphite offers good electrical conductivity, but it still falls short of metals like copper. Additionally, its layered structure poses challenges for miniaturization in electronics. These limitations have prompted scientists to explore ways to peel graphite down to a single, ultrathin layer. In 2004, the breakthrough isolation of a single layer of carbon atoms—graphene—marked a new era in material science.

Graphite as the Precursor to Graphene: A Continuing Role

As the precursor material for graphene, graphite continues to play a crucial role in modern technology. It remains not only an important raw material for high-end industrial production but also a key source for obtaining graphene. With the advancement of science and technology, graphite is gradually transitioning from a traditional industrial material to the core of a new materials revolution.

The successful isolation of graphene from graphite has opened up revolutionary possibilities in electronics, energy storage, and aerospace. However, graphite itself remains indispensable, bridging the gap between conventional industrial uses and cutting-edge technological innovations.

This article aims to provide a comprehensive review of graphene’s past and present. We will explore the origins and traditional applications of graphite, the ancient material from which graphene was derived, and analyze graphene’s role in today’s technology landscape across various industries. Additionally, we will examine the current state of its commercialization and industry development. Finally, we will look into graphene’s future potential and challenges, highlighting its role in driving the next wave of technological revolutions.

Compared to conventional materials like silicon, copper, or carbon fiber, graphene stands out for its single-atom thickness, exceptional electrical conductivity, mechanical strength, and superior thermal properties. While traditional materials each have their strengths, none can match graphene’s versatility across so many areas. As a result, graphene not only offers new solutions for existing technologies but also promises to become a key material for future high-tech industries. Its remarkable properties make it not just a marvel of material science but also a critical catalyst for the next generation of technological advancements.

III. The Discovery of Graphene and Scientific Breakthroughs

1. Discovery of Graphene and the Nobel Prize

The discovery of graphene represents a groundbreaking achievement in material science. In 2004, two scientists from the University of Manchester, Andre Geim and Konstantin Novoselov, successfully isolated a single layer of carbon atoms from graphite through a simple yet ingenious experiment. Using common adhesive tape, they repeatedly peeled the surface of graphite, ultimately obtaining a one-atom-thick carbon sheet—graphene. This technique, known as mechanical exfoliation, unveiled the hidden potential of two-dimensional (2D) materials that had previously gone unnoticed.

The preparation of graphene was not only an experimental feat but also introduced a novel class of material to the scientific world. For their pioneering discovery, Geim and Novoselov were awarded the 2010 Nobel Prize in Physics. The Nobel Committee commended their work as “opening up a new field of 2D material science,” marking graphene’s immense scientific value and inspiring worldwide research into its potential.

The discovery of graphene holds significance far beyond academia, promising revolutionary applications across various industries. From electronics to energy systems, the arrival of graphene paves the way for future technological advancements. This breakthrough has also attracted substantial investments and research efforts into the development and commercialization of graphene-based technologies.

2. Unique Properties of Graphene

Graphene has garnered significant attention due to its remarkable properties. As a single atomic layer of carbon, it combines several exceptional characteristics, making it superior to many conventional materials. Its unique structure and physical properties offer unprecedented opportunities for applications across multiple fields.

- Ultra-thin, 2D Crystal Structure

Graphene is the thinnest known material, consisting of a single layer of carbon atoms with a thickness of approximately 0.34 nanometers. This ultra-thin structure not only provides high flexibility and transparency but also offers distinct advantages for miniaturization in nanotechnology and microdevices. - Mechanical Properties: 200 Times Stronger Than Steel

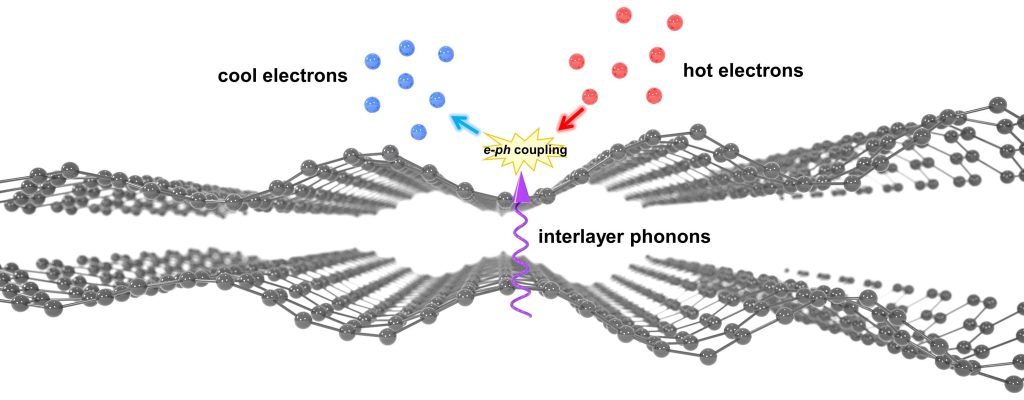

Despite its atomic thinness, graphene is 200 times stronger than steel under ideal conditions. It is also highly flexible and stretchable, capable of bending without breaking. These attributes make graphene an ideal material for flexible electronics and composite materials with high strength-to-weight ratios. - Electrical Properties: High Electron Mobility and Zero Bandgap

Graphene exhibits exceptional electrical conductivity, with an electron mobility of up to 200,000 cm²/V·s, far surpassing that of traditional semiconductors like silicon. This enables extremely fast electrical responses, making graphene suitable for applications in transistors, sensors, and quantum computing. Additionally, as a zero-bandgap material, graphene provides high electrical conductivity, which could significantly enhance the performance of electronic devices. - Thermal Conductivity: Superior Heat Dissipation

Graphene’s thermal conductivity reaches up to 5000 W/m·K, several times higher than most metals. This makes graphene an ideal candidate for heat management applications in smartphones and high-performance electronics, where effective heat dissipation can extend the lifespan of components.

Graphene’s superior properties establish it as a material of the future, with the potential to replace traditional materials in electronics, aerospace, medicine, and energy sectors. Scientists are now focusing on ways to translate graphene’s potential into practical, commercial solutions.

The birth of graphene is not just an experimental triumph but the beginning of a new era in material science. By integrating strength, conductivity, thermal performance, and flexibility in a single material, graphene offers unparalleled research opportunities. It also serves as a critical enabler for future technological advancements, supporting human progress in ways previously unimaginable.

IV. Graphene Today: Diverse Applications Across Industries

With its outstanding electrical, mechanical, and thermal properties, graphene is making the leap from laboratory research to real-world applications. Below is an in-depth exploration of how graphene is transforming various industries, including electronics, energy, healthcare, aerospace, and environmental engineering.

1. Electronics and Semiconductors

Graphene Electrodes and Transistors

Graphene’s high electron mobility (around 200,000 cm²/V·s) makes it an exceptional candidate for next-generation semiconductor materials. Graphene-based transistors can transmit signals at ultra-fast speeds, potentially replacing traditional silicon transistors and paving the way for more powerful computing chips. Moreover, graphene’s superior electrical conductivity enhances circuit stability and reduces energy losses, contributing to more energy-efficient electronic devices.

Graphene Sensors

Thanks to its ultra-thin structure and high sensitivity, graphene can detect even the smallest changes in gases or chemicals. This makes it ideal for sensors used in industrial safety and environmental monitoring. For example, graphene-based air sensors can detect trace levels of toxic gases, playing a critical role in improving workplace safety and public health.

2. Energy Sector

Supercapacitors and Lithium Batteries

Graphene is revolutionizing energy storage technologies. Its large surface area and high conductivity make it a perfect electrode material for supercapacitors, enabling faster charging and discharging than conventional materials. In lithium batteries, graphene enhances charging speed and storage capacity, significantly extending battery life for smartphones, laptops, and electric vehicles.

Solar Cells

Graphene’s transparency and conductivity make it a promising material for solar cells. When used as an electrode, graphene improves light-to-electricity conversion efficiency while reducing production costs. Solar cells that combine graphene with new materials like perovskite show great potential, indicating a promising future for affordable renewable energy.

3. Healthcare and Biotechnology

Biosensors and Drug Delivery

Graphene membranes are being developed into biosensors for real-time detection of biological markers such as glucose and uric acid, essential for personalized healthcare. Graphene’s high sensitivity and conductivity enable accurate monitoring and early detection of diseases. In drug delivery systems, graphene-based nanomaterials can precisely release drugs, improving treatment outcomes and minimizing side effects.

Antibacterial Materials and Medical Implants

Graphene’s inherent antibacterial properties make it ideal for medical equipment. For example, graphene-coated wound dressings effectively prevent infections, speeding up recovery. Additionally, research is ongoing into using graphene for biocompatible implants such as cardiac stents and neural implants, promising more durable and safer medical solutions.

4. Aerospace and Defense Industries

Lightweight Materials

Graphene is 200 times stronger than steel yet has an extremely low density, making it a game-changer for lightweight composite materials. These composites can improve the structural strength of aircraft and automobiles while reducing weight, enhancing performance, and lowering fuel consumption and carbon emissions.

Stealth Materials and Radar Protection

Graphene’s conductivity offers immense potential in stealth technologies. By absorbing radar waves and minimizing reflected signals, graphene-based coatings improve the stealth capabilities of military aircraft and naval vessels. This strategic application is critical to the development of next-generation defense technologies.

5. Environmental Engineering

Water Treatment and Air Purification

Graphene membranes demonstrate exceptional filtration capabilities, making them effective for desalination and wastewater treatment. These membranes can efficiently separate impurities while conserving energy. Additionally, graphene is being incorporated into air purifiers to capture fine particles and toxic gases, helping to improve air quality in urban environments.

Hydrogen Storage and Green Energy

Graphene and its derivatives play a crucial role in the development of hydrogen storage technologies, essential for the advancement of hydrogen fuel cells. Due to its large surface area and unique structure, graphene can store substantial amounts of hydrogen, paving the way for clean energy solutions such as fuel-cell vehicles and renewable energy systems.

Graphene’s diverse applications represent not only a leap forward in material science but also a driving force for technological innovation across various sectors. From electronics to energy, healthcare to defense, graphene is gradually transforming the way we live and work, bringing us closer to a smarter and more sustainable future.

As research progresses, scientists are unlocking even more possibilities for graphene. Its unparalleled properties, combined with advances in commercialization, are expected to revolutionize industries in the coming years, contributing significantly to global sustainability efforts.

V. Development and Current Status of the Graphene Industry: Production and China’s Industrial Layout

1. Global and China’s Graphene Industry Development

Since the discovery of graphene in 2004, research institutions and enterprises worldwide have heavily invested in its production and application, gradually forming a complete industrial chain from R&D to commercialization. In Europe and North America, institutions like the University of Manchester, IBM, and MIT are leading in fundamental graphene research and technological innovation. South Korea’s Samsung has also made significant progress in applying graphene in batteries and sensors for consumer electronics.

China, as the largest graphite producer globally, is actively developing its graphene industry chain. Several cities, including Changzhou, Qingdao, and Wuxi, have become graphene hubs, attracting numerous companies and research institutes. Qingdao, known for its abundant natural graphite resources, has fostered many graphene-focused enterprises, such as Qingdao Haoxin Graphene Technology Co., Ltd.. Meanwhile, Changzhou has established the China Innovation Alliance of the Graphene Industry, facilitating collaboration between government, academia, and industry to accelerate graphene commercialization. Shenzhen and Chongqing are also advancing graphene applications in consumer electronics and energy technologies.

2. Graphene Production Processes and Technical Challenges

Current industrial graphene production relies mainly on two methods:

- Mechanical Exfoliation:

This technique, the earliest used to isolate graphene, involves peeling layers from graphite to obtain single or few-layer graphene. Although it yields high-quality graphene, it is not suitable for mass production. - Chemical Vapor Deposition (CVD):

CVD is the most widely used technique in industry, where carbon atoms are deposited on a metal substrate to form graphene films. This method enables the large-scale production of graphene films, making it ideal for electronics, sensors, and display technologies.

However, cost control remains a significant challenge. CVD production involves expensive equipment and complex processes, driving up the price of graphene products. On the other hand, while mechanical exfoliation offers high quality, it is not scalable. Chemical reduction methods, though more cost-effective, yield lower-quality graphene, limiting its use in high-end applications.

To address these challenges, researchers are exploring new production techniques, such as electrochemical exfoliation and biocatalytic methods, which offer potential for cost-effective and scalable production. Companies are also seeking to integrate upstream and downstream supply chains to enhance graphene production efficiency and facilitate market penetration.

China has made significant strides in establishing a graphene industry chain and developing regional industrial clusters. Despite the challenges of high production costs, quality control, and technological maturity, government policies and research investments are driving graphene toward commercialization. As production techniques continue to improve, graphene is poised to become a key material in the next wave of industrial and technological revolutions, positioning China to play a leading role in global materials science.

VI. Future Prospects and Challenges

1. Graphene’s Potential in Future Industries

Graphene’s unique properties position it as a critical material in emerging technologies:

- Artificial Intelligence (AI) and Quantum Computing

Thanks to its high electron mobility and excellent conductivity, graphene holds promise as a key material for next-generation quantum computers. In quantum devices, graphene can facilitate high-speed data transfer and precise circuit control, supporting the widespread adoption of quantum computing. Additionally, graphene-based sensors and chips can significantly enhance AI systems by delivering faster processing speeds and enabling more advanced algorithms. - Support Material for 5G/6G Communication Technologies

As communication technology advances toward 6G, devices demand higher speeds, stability, and energy efficiency. Graphene films, with their superior conductivity and transparency, are ideal for use in high-frequency components, antennas, and filters. Moreover, graphene’s thermal conductivity offers a solution to the heat dissipation challenges of base stations and communication equipment, ensuring long-term stable operation.

2. Current Challenges and Solutions

Despite its promising applications, the commercialization of graphene faces significant challenges:

- Mass Production and Technical Breakthroughs

Achieving large-scale production of high-quality graphene is a central issue. While mechanical exfoliation produces pure graphene, it is not scalable and incurs high costs. CVD is suitable for mass production but still requires improvements in uniformity and quality. Future breakthroughs may lie in electrochemical exfoliation or plasma processes, which could reduce costs, increase output, and achieve standardization in quality. - Eco-Friendly Processes and Sustainable Development

Many current graphene production methods rely on large amounts of chemical reagents, posing environmental risks. To align with sustainability goals, the industry is exploring green production technologies, such as the use of biodegradable materials and environmentally friendly waste treatment methods. The development of energy-efficient and eco-friendly processes will be essential for the long-term growth of the graphene industry.

Graphene, as a revolutionary material, holds enormous potential in future technologies, especially in AI, quantum computing, and next-generation communication systems. However, scalable production and eco-friendly manufacturing processes remain key bottlenecks. With advances in science and the maturation of the industrial chain, graphene’s widespread application will further accelerate technological innovation and lay the foundation for a smarter, greener economy.

VII. Conclusion

Graphene, as both an extension and breakthrough of graphite, has transformed from an ancient material into a pioneer of high technology. Its discovery has not only ushered in a new era of two-dimensional materials but has also sparked revolutionary applications across multiple sectors—from electronics and energy to healthcare and defense. Graphene is steadily reshaping the technological landscape of various industries.

Looking ahead, graphene will play a vital role in artificial intelligence, quantum computing, and next-generation communication technologies, accelerating society’s transition toward intelligent and sustainable development. While the road to industrialization presents challenges in mass production and environmental sustainability, continuous technological advancements and deeper applications will unlock graphene’s full potential. Graphene is poised to become a driving force in future innovations, offering new momentum for sustainable growth and human progress.

VIII. References and Appendix

- Geim, A. K., & Novoselov, K. S. (2004). The rise of graphene. Nature Materials, 6(3), 183-191.

- Novoselov, K. S., et al. (2005). Two-dimensional gas of massless Dirac fermions in graphene. Nature, 438(7065), 197-200.

- Zhu, Y., et al. (2010). Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Advanced Materials, 22(35), 3906-3924.

- 青岛昊鑫石墨烯科技有限公司 (2022). 中国石墨烯产业白皮书(2022年版).

- 曹原, 吴海龙. (2019). 石墨烯的产业化发展与挑战. 中国材料科学学报, 45(12), 1234-1243.

- China’s graphene strategy: How the next industrial revolution is unfolding. (2023). Financial Times.

- Global Graphene Industry Report 2022. (2022). IDTechEx Market Research.

These references cover graphene’s foundational research, technological developments, industrial landscape, and future trends, providing both theoretical insights and practical data for this report.