The Promise of Reduced Graphene Oxide (rGO): Properties, Production, and Applications

Reduced graphene oxide (rGO) is a derivative of graphene oxide (GO) that is partially restored to a graphene-like structure through various reduction processes. This restoration significantly enhances the material’s electrical conductivity and stability, making it a versatile and high-performing material for numerous applications. In this article, we explore the methods of producing rGO, its advantages, and the industries where it is driving innovation.

1. What is Reduced Graphene Oxide (rGO)?

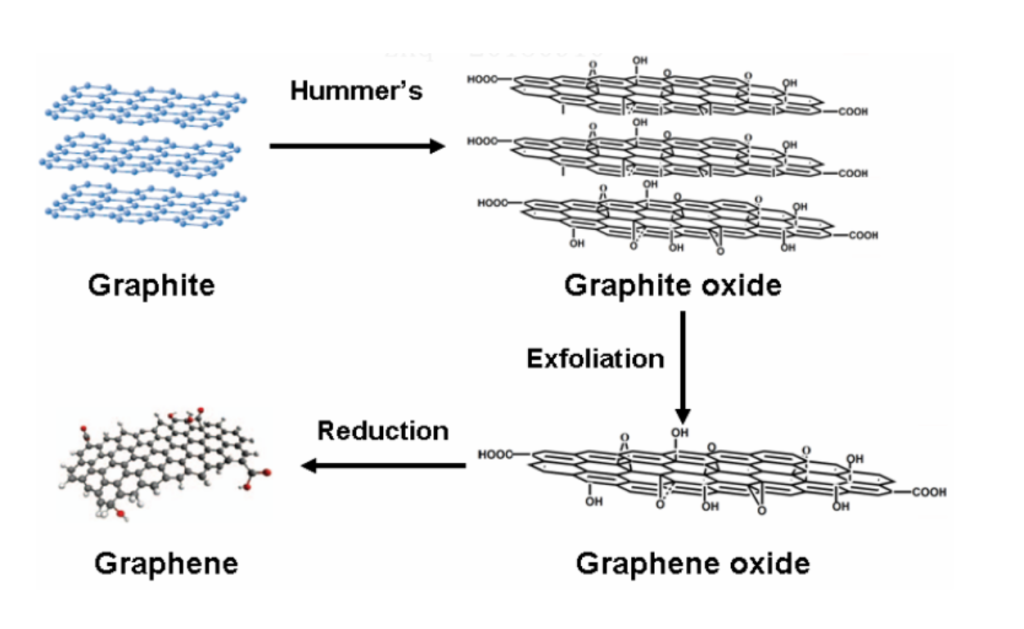

Reduced graphene oxide is obtained by reducing graphene oxide (GO) to remove a portion of its oxygen-containing functional groups. While it does not completely return to pristine graphene due to residual defects and oxygen groups, the reduction process restores much of the electrical conductivity and other properties that make graphene exceptional.

This partial restoration creates a material with a unique balance of functionality and performance: rGO retains some of the chemical versatility of GO while offering high electrical conductivity and a large specific surface area. These characteristics make it highly attractive for advanced applications in electronics, energy storage, sensing, and photonics.

2. Production Methods of Reduced Graphene Oxide

Reduced graphene oxide is synthesized by applying reduction techniques to graphene oxide. The choice of reduction method significantly influences the properties of the resulting rGO, such as its level of conductivity, stability, and functional group composition. Below are the main production methods:

2.1 Chemical Reduction

Chemical reduction involves treating graphene oxide with chemical agents that remove oxygen-containing groups. Common reducing agents include:

- Hydrazine Hydrate: A widely used reducing agent that effectively restores electrical conductivity to rGO.

- Sodium Borohydride (NaBH₄): Offers milder reduction conditions, which may preserve more structural integrity in rGO.

- Ascorbic Acid (Vitamin C): A greener alternative that provides moderate reduction and is environmentally friendly.

Chemical reduction is cost-effective and scalable, making it one of the most popular methods for producing rGO.

2.2 Thermal Reduction

Thermal reduction involves heating graphene oxide at high temperatures (typically above 1,000°C) in an inert or reducing atmosphere, such as nitrogen, argon, or hydrogen. The high temperatures remove oxygen groups and restore the sp²-bonded carbon lattice.

This method produces rGO with high conductivity and minimal residual oxygen, but it requires specialized equipment and consumes significant energy.

2.3 Electrochemical Reduction

In electrochemical reduction, an electrical current is applied to GO dispersed in an electrolyte solution, causing the removal of oxygen groups. This technique allows precise control over the reduction process and avoids the use of hazardous chemicals. However, it may not be as scalable as chemical or thermal reduction.

2.4 Microwave-Assisted Reduction

Microwave-assisted reduction is a relatively fast and energy-efficient method. Graphene oxide is exposed to microwave radiation, which generates localized heating and triggers rapid reduction. This approach is particularly attractive for large-scale production.

3. Advantages of Reduced Graphene Oxide

Reduced graphene oxide offers a unique combination of properties that make it suitable for advanced technological applications. Some of the key advantages include:

3.1 High Electrical Conductivity

The reduction process restores much of the electrical conductivity lost in GO, making rGO an excellent material for applications requiring high-performance electrical or electronic components.

3.2 Large Specific Surface Area

rGO retains the two-dimensional structure of graphene, giving it a large surface area. This property is critical for energy storage applications like supercapacitors and batteries, where surface area impacts charge storage capacity.

3.3 Good Stability

Reduced graphene oxide exhibits good thermal, chemical, and mechanical stability, enabling its use in harsh or demanding environments. It can maintain its properties under high temperatures or prolonged operation.

3.4 Customizable Properties

The residual functional groups on rGO’s surface allow further chemical modification, enabling its use in tailored applications, such as composites or sensing materials.

4. Applications of Reduced Graphene Oxide

Reduced graphene oxide has found applications across various high-tech industries, from energy storage to optoelectronics. Below, we delve into some of its most promising use cases:

4.1 Energy Storage: Supercapacitors and Lithium-Ion Batteries

Energy storage is one of the most prominent applications of rGO. Its high conductivity, large surface area, and stability make it an excellent candidate for use in supercapacitors and lithium-ion batteries (LIBs).

- Supercapacitors: rGO is widely used as an electrode material in supercapacitors due to its high surface area and conductivity. It enables rapid charge and discharge cycles, making supercapacitors ideal for applications requiring burst energy delivery, such as in electric vehicles or power backup systems.

- Lithium-Ion Batteries: In LIBs, rGO serves as an advanced anode or cathode material. It improves the battery’s energy density, cycle life, and charge-discharge rates. This contributes to the development of high-performance batteries for consumer electronics, electric vehicles, and renewable energy systems.

4.2 Sensors

Reduced graphene oxide is a versatile material for sensor applications due to its high sensitivity to environmental changes and the presence of residual functional groups.

- Gas Sensors: rGO-based gas sensors can detect trace amounts of gases such as ammonia, nitrogen dioxide, and carbon monoxide. The high conductivity of rGO allows for quick response and recovery times.

- Humidity Sensors: The functional groups on rGO’s surface interact with water molecules, making it suitable for detecting humidity levels with high precision.

4.3 Optoelectronics

In optoelectronic devices, rGO plays a crucial role as a transparent conductive material, a photodetector, or an active layer in photovoltaics.

- Photodetectors: rGO can be used to fabricate photodetectors for detecting light across a broad spectrum, from ultraviolet to infrared. Its tunable properties allow for the design of devices with high sensitivity and fast response times.

- Photovoltaics: rGO is being explored as a component in next-generation solar cells. Its ability to conduct electricity while remaining lightweight and flexible makes it attractive for flexible and wearable solar technologies.

4.4 Composites and Coatings

The addition of rGO to polymers, metals, or ceramics enhances the mechanical, thermal, and electrical properties of the host material.

- Structural Composites: rGO-reinforced composites are used in aerospace, automotive, and construction industries to produce lightweight, durable materials with improved performance characteristics.

- Conductive Coatings: rGO-based coatings provide electrical conductivity, anti-corrosion properties, and thermal management capabilities, making them valuable for electronics, heat sinks, and protective finishes.

5. Challenges and Future Perspectives

While rGO has demonstrated significant promise, challenges remain in its commercialization. Key issues include achieving consistent quality in large-scale production, optimizing reduction methods to balance cost and performance, and overcoming limitations associated with residual defects.

Looking ahead, the continued development of advanced reduction techniques and hybrid materials combining rGO with other nanomaterials is expected to unlock new applications. rGO will likely play a pivotal role in next-generation energy devices, flexible electronics, and sustainable technologies.

6. Conclusion

Reduced graphene oxide is a powerful material that bridges the gap between graphene oxide’s versatility and pristine graphene’s exceptional properties. Its unique combination of conductivity, surface area, and modifiability has positioned it as a cornerstone in the development of advanced materials and technologies.

From energy storage to sensors and optoelectronics, rGO’s applications span a wide range of industries, making it an indispensable material in modern nanotechnology. As research progresses and production methods evolve, rGO is poised to make an even greater impact on the future of science and engineering.