The Role of Graphene in Thermal Management for Smart Manufacturing: Enhancing Device Performance and Stability

Introduction

In the era of smart manufacturing, efficiency, and performance are paramount. As industries adopt advanced automation, robotics, and IoT devices, the need for effective thermal management has become crucial. Among the most promising materials for this challenge is graphene—a material that is revolutionizing multiple industries due to its remarkable thermal conductivity and other unique properties. This article explores how graphene can optimize thermal management, prevent overheating, and enhance the stability of manufacturing devices, offering a significant competitive edge in the rapidly growing smart manufacturing sector.

Understanding Graphene’s Thermal Properties

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. This simple structure imparts extraordinary properties, particularly high thermal conductivity—far superior to most other materials.

-

Thermal Conductivity of Graphene: Graphene has an impressive thermal conductivity of over 5000 W/m·K, making it one of the most effective heat conductors discovered. This is several times higher than traditional metals like copper, making it an ideal material for heat dissipation in high-performance devices.

-

Benefits in Thermal Management: The ability of graphene to efficiently spread heat across its surface means that it can prevent localized overheating, a common issue in high-performance electronics and manufacturing equipment. This results in more stable and longer-lasting equipment, which is crucial in industrial environments.

Graphene as a Thermal Conductor in Manufacturing Devices

Thermal management is particularly vital in smart devices and automated systems, where the efficiency and durability of machinery are critical. Graphene can be incorporated into several components of smart manufacturing systems to improve their thermal stability:

-

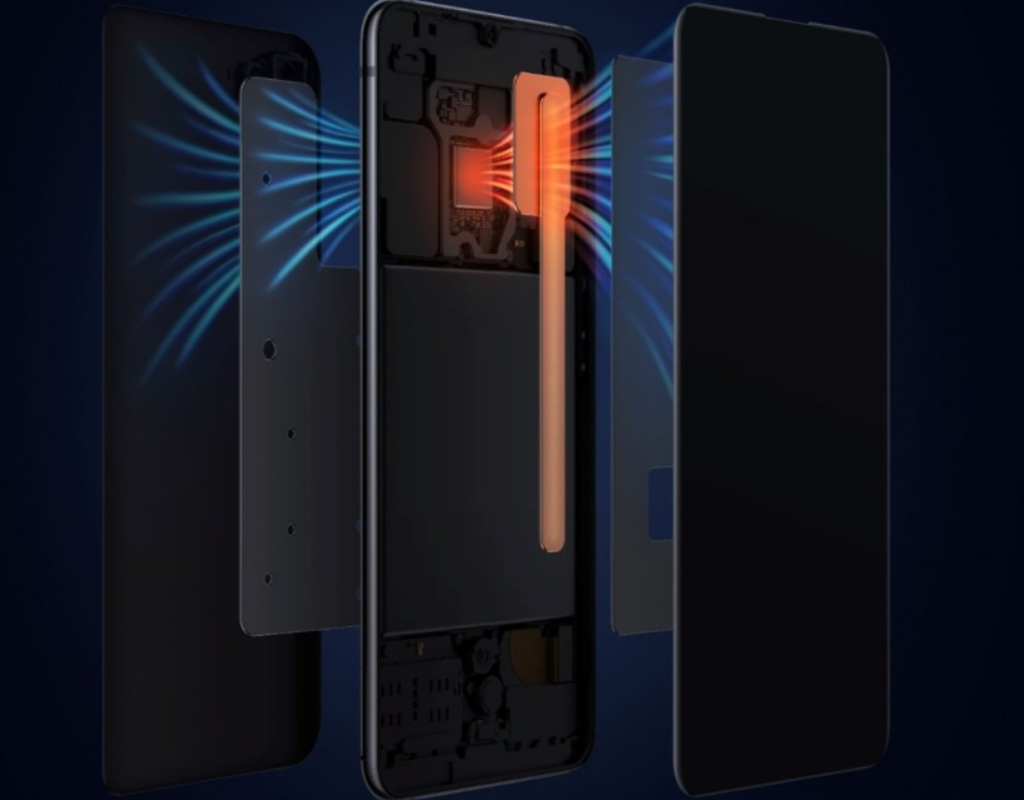

Graphene-based Heat Sinks: Graphene can be used to create efficient heat sinks, which are designed to absorb and dissipate excess heat from electronic components like microprocessors and power supplies. This ensures that sensitive components are not exposed to heat stress, which can degrade their performance over time.

-

Graphene-enhanced Cooling Systems: Graphene can be used in combination with other materials to create hybrid cooling systems. For example, graphene can be added to water-based coolants or combined with polymers to create more effective thermal interface materials. These systems are ideal for cooling larger machinery in automated factories or robotic systems.

-

Graphene Composite Materials: By integrating graphene into other materials, such as ceramics, polymers, or metals, manufacturers can create graphene composites that have both structural strength and thermal conductivity. These materials can be used in a variety of applications, from industrial robots to automated assembly lines.

The Advantages of Graphene in Thermal Management

The advantages of graphene’s thermal properties extend far beyond its raw heat conductivity. Here’s a breakdown of the key benefits it provides in smart manufacturing:

-

Enhanced Efficiency: Effective heat dissipation improves the efficiency of manufacturing systems. As machines and electronics maintain optimal operating temperatures, they can function at peak performance without the need for frequent downtime due to overheating.

-

Increased Lifespan of Equipment: Overheating is one of the main causes of wear and tear in industrial devices. Graphene’s ability to regulate heat helps extend the lifespan of equipment by protecting sensitive components from thermal degradation.

-

Compact Design: Graphene’s incredible heat conductivity allows for more compact thermal management solutions. Manufacturers can create smaller, lighter, and more energy-efficient devices without compromising on performance or durability.

-

Sustainability: By improving the efficiency of smart manufacturing systems, graphene helps reduce energy consumption. Efficient heat dissipation minimizes the need for high-energy cooling systems, contributing to green manufacturing practices and reducing operational costs.

Applications of Graphene in Smart Manufacturing Devices

Given its versatile properties, graphene has already begun to find applications in a wide range of smart devices used in manufacturing. Here are some key areas where graphene is making a significant impact:

-

Robotic Systems: Industrial robots, especially those used in automated assembly lines, rely on efficient thermal management to operate at high speeds and precision. Graphene-based materials in robotic components help reduce overheating and ensure continuous operation.

-

Autonomous Machines: Autonomous vehicles and mobile robots used in manufacturing and warehouses require efficient thermal management to ensure their electronic systems perform without failure. Graphene can be integrated into these systems to optimize heat flow and prevent overheating.

-

Sensors and IoT Devices: The Internet of Things (IoT) is transforming manufacturing by connecting various devices for real-time data collection and analysis. Graphene’s exceptional thermal properties are particularly useful in sensor systems, where heat fluctuations can affect sensor accuracy and device reliability.

-

Energy-efficient Lighting: In modern smart factories, energy-efficient LED lights are essential. Graphene is increasingly being used in LED thermal management, where it helps dissipate heat from light-emitting diodes, ensuring longer lifespans and better efficiency.

-

Advanced Electronics: Printed electronics and flexible displays in smart manufacturing equipment can benefit from graphene’s thermal properties, ensuring that electronic components such as microchips, processors, and batteries don’t overheat, extending the device’s functionality and lifespan.

-

Battery Management Systems: As electric vehicles (EVs) and battery-powered machinery become more common in manufacturing, graphene can be used to enhance the heat dissipation in battery management systems, helping to improve energy efficiency and charge cycles.

Market Potential and Growth Opportunities

The integration of graphene into smart manufacturing’s thermal management systems presents numerous market opportunities, both in terms of technological innovation and economic benefits.

-

Growing Demand for Advanced Thermal Management: As industries move towards high-performance automation, robotics, and IoT, the demand for effective thermal management will continue to increase. Graphene is poised to become a key material in this space, thanks to its unique properties and versatility.

-

Expansion in Electronics: The consumer electronics and industrial electronics markets are expected to see significant growth in the coming years. Graphene’s ability to improve the performance of electronics through superior thermal management will drive demand in these sectors, particularly in the development of wearables, smart sensors, and 5G networks.

-

Sustainability in Manufacturing: The global push towards sustainable manufacturing opens doors for graphene-based solutions. Graphene’s ability to enhance energy efficiency and reduce waste positions it as a green material that helps manufacturers reduce their environmental impact and operating costs.

Conclusion

Graphene’s superior thermal conductivity makes it an invaluable material in the world of smart manufacturing. By effectively managing heat, graphene enhances the stability, efficiency, and lifespan of manufacturing devices, ensuring high performance even under demanding conditions. As industries continue to adopt automation and advanced technologies, graphene’s role in thermal management will only become more critical. The integration of graphene into manufacturing systems promises to unlock new levels of efficiency, sustainability, and innovation, driving the growth of a smart manufacturing future.